Coating and method capable of decreasing uncoated areas of curtain

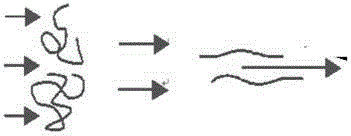

A curtain coating and coating technology, used in paper coatings, coatings, textiles and papermaking, etc., can solve the problems of high vehicle speed and low coating amount, and achieve improved coverage quality, low solid content, and good extension. The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A paint that can improve the whiteness of curtain coating. The composition and dosage of raw materials are: wheat starch: 50 parts; phosphorylated potato starch: 12 parts; styrene-butadiene latex: 6 parts; polyacrylamide: 0.5 parts; microcapsules: 100 parts parts; polyamide polyurea epichlorohydrin: 0.8 parts; 0.3 parts of succinate sulfonate, 0.3 parts of sodium hydroxide.

[0037] Add each raw material in sequence according to the above formula, and disperse at high speed to obtain a uniform coating. The solid content of the paint is 28%, the viscosity is 108cps, and the surface tension is 28mN / m.

[0038] Purchase the common common paint on the market separately, and send Styron Company together with the paint prepared by the present invention to test the extensional viscosity with an ACAV ultra-high shear viscometer. The test results are shown in Figure 4 .

[0039] The extended viscosity (viscosity) is represented by the Euler number at different shear rates. Th...

Embodiment 2

[0042] A kind of paint that can improve the whiteness of curtain coating. The raw material composition and dosage are: hydroxymethyl cellulose: 65 parts; acetate corn starch: 6 parts; styrene-acrylic latex: 8 parts; vinyl acetate resin: 1 part; Capsule: 80 parts; Melamine formaldehyde resin: 1 part; Sodium alkylbenzene sulfonate: 0.1 part; Disodium hydrogen phosphate: 0.5 part.

[0043] Add each raw material in sequence according to the above formula, and disperse at high speed to obtain a uniform coating. The solid content of the paint is 27%, the viscosity is 100cps, and the surface tension is 27.5mN / m.

Embodiment 3

[0045]A paint that can improve the whiteness of curtain coating. The composition and dosage of raw materials are: wheat starch: 70 parts; phosphorylated wheat starch: 20 parts; vinegar-acrylic latex: 2 parts; epoxy resin: 0.8 parts; microcapsules: 120 parts parts; glyoxal: 0.5 parts; acetylene glycol: 0.5 parts, ammonia water: 0.5 parts.

[0046] Add each raw material in sequence according to the above formula, and disperse at high speed to obtain a uniform coating. The solid content of the paint is 25%, the viscosity is 90cps, and the surface tension is 26.9mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com