Special general polymer material for machine cleaning and preparation method thereof

A polymer and general-purpose technology, which is applied in the field of general-purpose polymer washing machine special materials and its preparation, can solve the problems of high storage conditions for active agents, environmental pollution, damage to equipment, etc., and achieve easy use, storage and transportation, and guarantee Machine washing effect and high washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preparation methods of Examples 1-4 provided by the present invention include the following steps:

[0028] S01. Preparation of modified polymer alloy: Weigh high-density polyethylene, polymethyl methacrylate and calcium carbonate fillers according to the weight percentages in Table 1, and first add high-density polyethylene and polymethyl methacrylate to 300 Fully mix for 5 minutes in a high-speed mixer at revolutions per minute, then add the calcium carbonate filler to the high-speed mixer and stir for 12 minutes, and then extrude, stretch, water-cool, and pelletize the modified polymerization through a co-rotating twin-screw machine. Material alloy

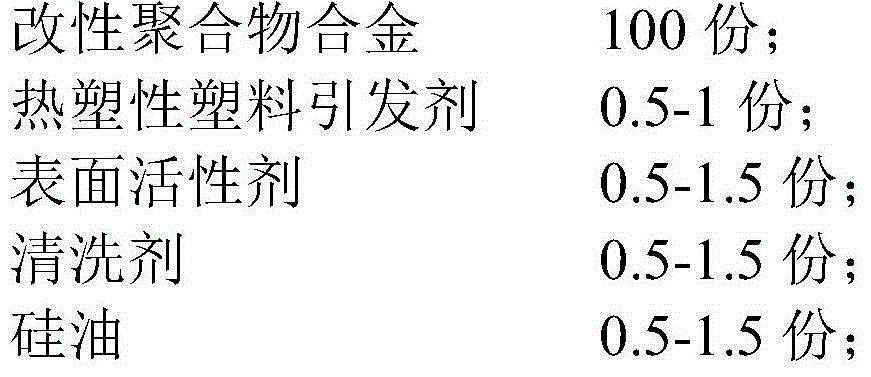

[0029] S02. Weigh the modified polymer alloy prepared in step S01 according to the parts by weight in Table 2, and add it to the low-speed high-speed mixer, and then add silicone oil according to the parts by weight in Table 2 through the air gun atomization device, and stir for 3 minutes ;According to the weight parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com