MnCoNi oxide ceramic infrared sensitive element densifying method

An oxide ceramic and densification technology, applied in the field of infrared detectors, can solve problems such as poor mechanical strength, increased detector noise, voids, etc., to achieve improved electrical performance qualification rate, reduced internal damage, and good process stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

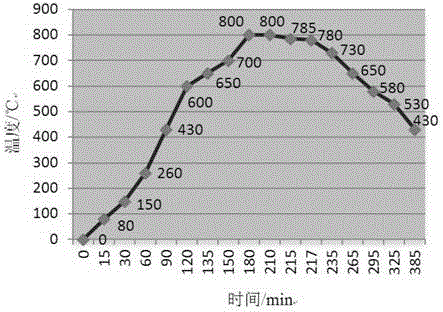

[0058] Embodiment 1 (width is the sensitive element flake of 130 μm)

[0059] Concrete implementation steps of the present invention are as follows:

[0060] (1) Preparation of sensitive element flakes:

[0061] The first step is to prepare MnCoNi oxide powder according to the MnCoNi atomic ratio of 52:32:16, and spread the powder evenly between two plexiglass plates to form a circular area of about Φ5cm~8cm;

[0062] In the second step, place the above-mentioned double-layer plexiglass plate in the hydraulic press, and keep the pressure for 10s after the pressure reaches 15±0.1MPa;

[0063] The third step is to open the plexiglass plate after the pressure is removed from the hydraulic press, and gently sweep the pressed sheet from the plexiglass plate onto the glass plate with a small brush, and use a measuring microscope equipped with a special blade holder to cut the sheet with a special blade It is a strip with a width of 0.17mm to 0.20mm and a length of not less than ...

Embodiment 2

[0102] Embodiment 2 (width is the sensitive element sheet of 300 μm)

[0103] Concrete implementation steps of the present invention are as follows:

[0104] (1) Preparation of sensitive element flakes:

[0105] The first step is to prepare MnCoNi oxide powder according to the MnCoNi atomic ratio of 52:32:16, and spread the powder evenly between two plexiglass plates to form a circular area of about Φ5cm~8cm;

[0106] In the second step, place the above-mentioned double-layer plexiglass plate in the hydraulic press, and keep the pressure for 10s after the pressure reaches 15±0.1MPa;

[0107] The third step is to open the plexiglass plate after the pressure is removed from the hydraulic press, and gently sweep the pressed sheet from the plexiglass plate onto the glass plate with a small brush, and use a measuring microscope equipped with a special blade holder to cut the sheet with a special blade It is a strip with a width of 0.38mm to 0.43mm and a length of not less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com