Molasses addition system of mixer and molasses addition technology of molasses addition system

A technology of organic molasses and molasses, which is applied in the field of mixer molasses adding system and molasses adding process, which can solve the problems of inability to add, molasses leakage, and difficult addition, etc., to facilitate transportation and processing, reduce work pressure, and facilitate uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

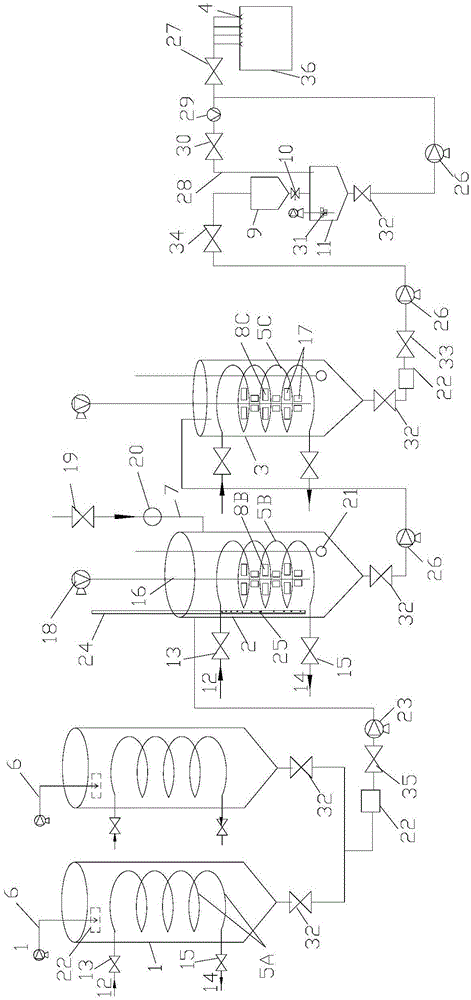

[0027] refer to figure 1 , this embodiment includes a raw material tank 1, a dilution tank 2, a storage tank 3, a metering component, and a nozzle 4 that are sealed and connected by pipelines,

[0028] The raw material tank 1 comprises a raw material tank body, a heating coil 5A, and a feed pipe 6, and the discharge port of the raw material tank body is connected with the feed port of the dilution tank 2;

[0029] The dilution tank 2 includes a dilution tank body, a heating coil 5B, a water inlet pipe 7, and an agitator 8B. The water inlet pipe 7 is connected to the upper part of the dilution tank body, and the agitator 8 is located in the center of the dilution tank body and passes through the heating coil pipe. 5B; the discharge port of the dilution tank is connected to the feed port of the storage tank 3;

[0030] The storage tank 3 includes a storage tank body, a heating coil 5C, and an agitator 8C. The agitator 8C is located in the center of the storage tank body and pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com