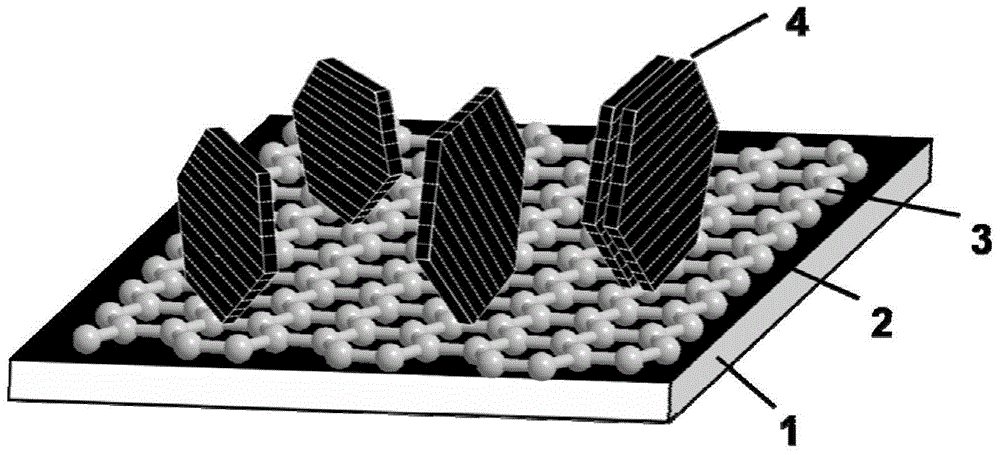

Titanium disulfide nano sheet/graphene composite material counter electrode and preparation method thereof

A technology of titanium disulfide and composite materials, applied in the field of solar cells, can solve the problems of large charge transfer resistance and comparable electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

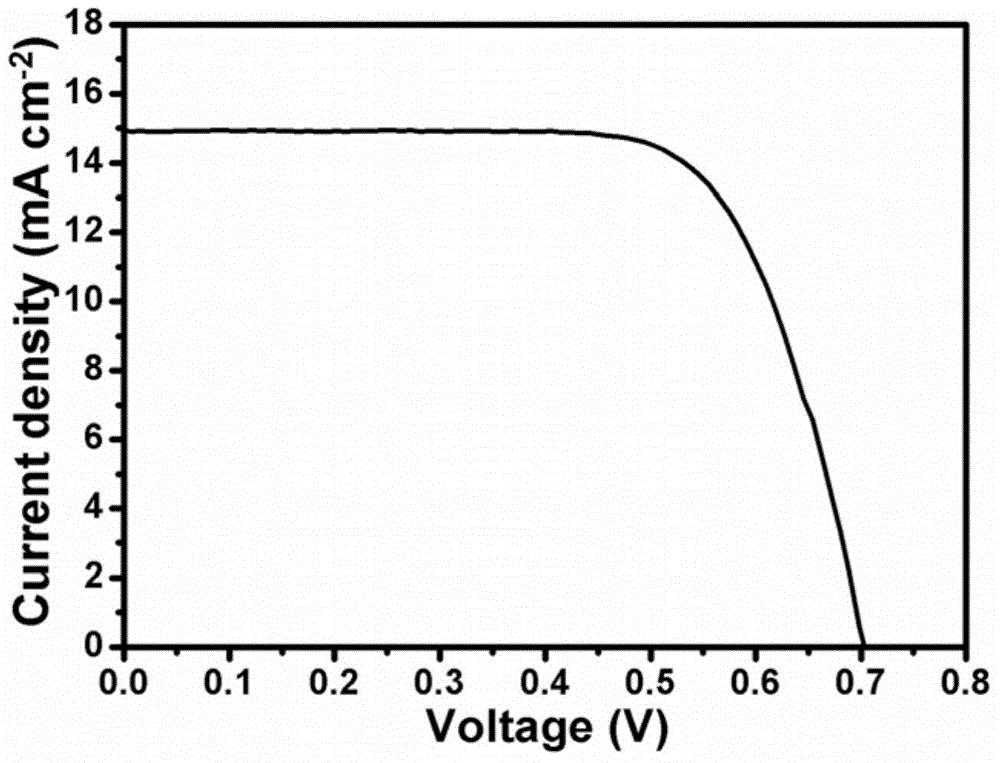

Examples

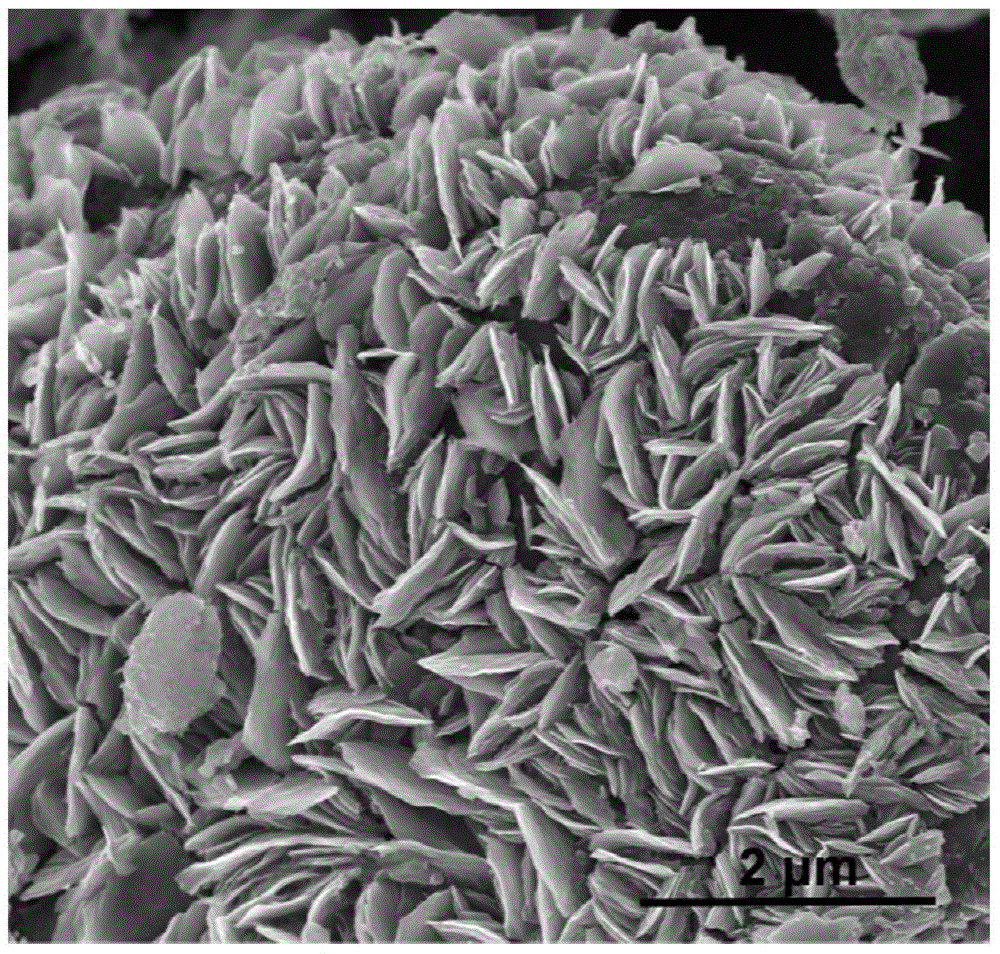

Embodiment 1

[0025] Weigh 0.2g of graphene oxide, 0.3g of titanium powder and 1.0g of sulfur powder respectively and place them in a 150mL stainless steel ball mill jar for ball milling pretreatment. The mass ratio of the material to stainless steel balls with a radius of 2.5mm was 1:50, the tank was protected by argon, the ball mill speed was 300r / min, and the ball milling time was 8h. After ball milling finishes, the resulting mixture is taken out from the ball mill jar, weigh 0.3g of the mixture and place it in the first ceramic boat, weigh 0.3g of sulfur powder and place it in the second ceramic boat, and place the first ceramic boat containing the mixture in the second ceramic boat. Upstream of the nitrogen gas flow, place the second ceramic boat filled with sulfur powder downstream of the nitrogen gas flow, the distance between the two ceramic boats is 1cm, heat-up annealing treatment, the temperature rises from room temperature to 600°C at a heating rate of 5°C / min, and keeps the tem...

Embodiment 2

[0027] Weigh 0.2g of graphene oxide, 0.2g of titanium powder and 0.5g of sulfur powder respectively and place them in a 150mL stainless steel ball mill jar for ball milling pretreatment. The mass ratio of the material to the stainless steel ball with a radius of 1.5mm is 1:80, the tank is protected by argon, the ball mill speed is 300r / min, and the ball milling time is 12h. After the ball milling, the resulting mixture is taken out of the ball mill tank , weighing 0.3g of the mixture is placed in the first ceramic boat, weighing 0.5g of sulfur powder is placed in the second ceramic boat, the first ceramic boat containing the mixture is placed upstream of the nitrogen gas flow, and the second ceramic boat containing the sulfur powder The ceramic boat is placed downstream of the nitrogen gas flow, the distance between the two ceramic boats is 0cm, and the temperature is raised to annealing treatment, the temperature is raised from room temperature to 650 °C at a heating rate of 5...

Embodiment 3

[0029] Weigh 0.2g of graphene oxide, 0.2g of titanium powder and 0.5g of sulfur powder respectively and place them in a 100mL stainless steel ball mill jar for ball milling pretreatment. The mass ratio of the material to the stainless steel ball with a radius of 1.5mm is 1:80, the tank is protected by argon, the ball mill speed is 400r / min, and the ball milling time is 12h. After the ball milling, the resulting mixture is taken out from the ball mill tank , take by weighing 0.3g mixture and place it in the first ceramic boat, take by weighing 0.5g sulfur powder and place it in the second ceramic boat, place the first ceramic boat containing the mixture on the upstream of the nitrogen gas flow, place the sulfur powder filled The second ceramic boat is placed downstream of the nitrogen gas flow, the distance between the two ceramic boats is 0 cm, the temperature is raised to annealing treatment, the temperature is raised from room temperature to 700 ° C at a heating rate of 10 ° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com