Biomass gas burner

A biomass gas and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of reduced combustion efficiency, small load adjustment range, low calorific value of biomass gas, etc., and achieve high thermal efficiency and high combustion efficiency. Completely full, stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

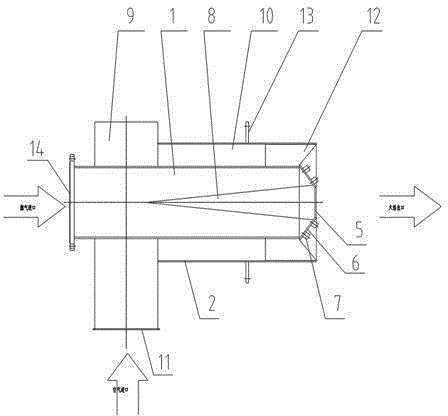

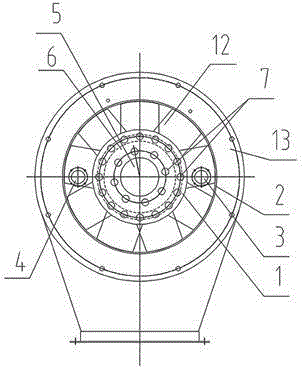

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as figure 1 , figure 2 As shown, the biomass gas burner includes a gas pipe 1 located at the axis, an air pipe 2 sleeved outside the gas pipe 1, an ignition device 3 and a flame detection device 4, and the rear end of the gas pipe 1 is provided with a gas inlet 14. The front end surface of the gas pipe 1 is composed of a circular sealing plate 5 whose front diameter is smaller than that of the gas pipe 1 and a conical surface 6 connecting the front edge of the pipe body and the circular sealing plate 5. On the conical surface 6 There are two circles of gas distribution nozzles 7 perpendicular to the conical surface 6. A booster cylinder 8 is arranged inside the gas pipe 1. The booster cylinder 8 is a conical cylinder. The large diameter end of the booster cylinder 8 is fixed on the circular seal. On the inner side of the plate 5, the booster tube 8 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com