A kind of rare earth aluminum alloy and preparation method thereof

A technology of aluminum alloy and aluminum alloy rod, which is applied in the field of alloy, can solve the problems of electrical properties and tensile properties to be improved, and achieve the effects of improving low-temperature anti-corrosion performance, improving processing plasticity, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

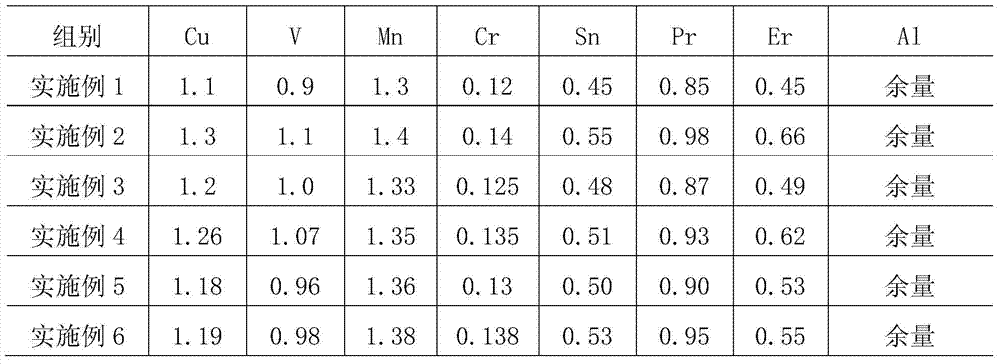

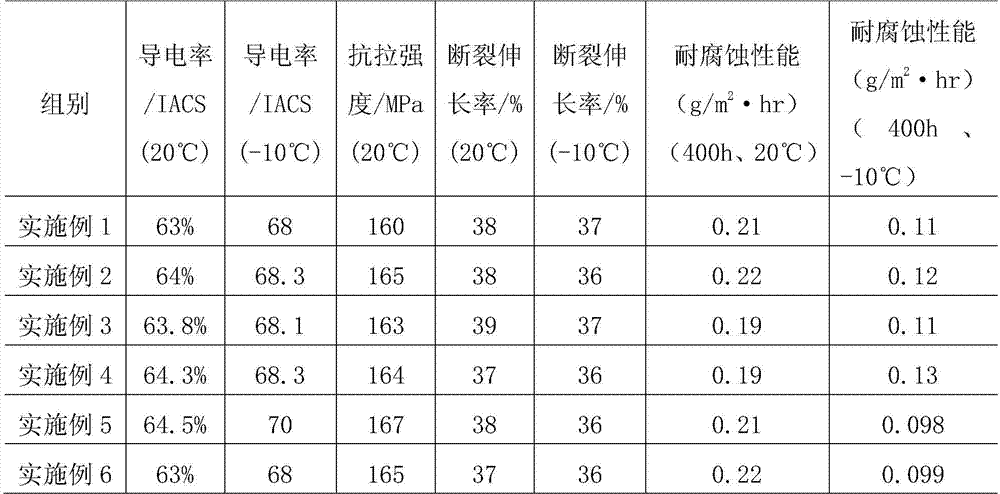

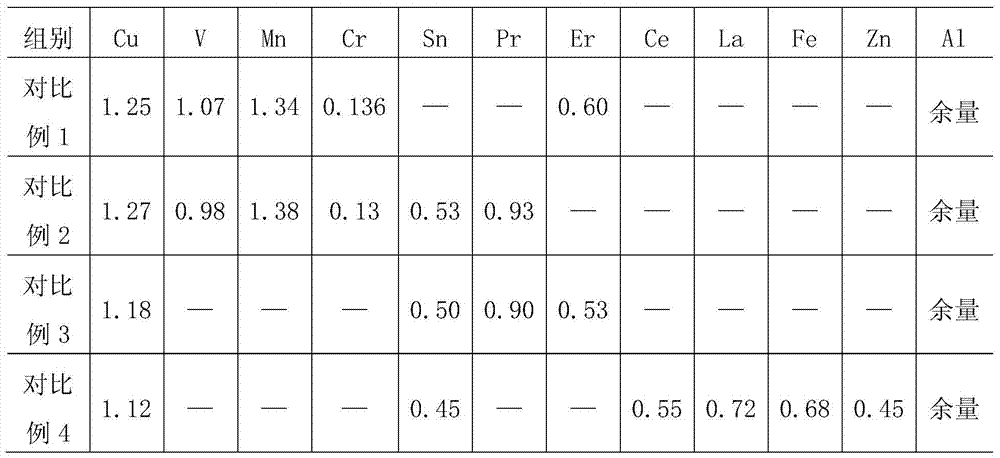

Examples

Embodiment 1

[0040] (1) Put the aluminum ingot into the melting furnace, heat it to 700°C to melt it, raise the temperature to 830°C, and keep it for 30 minutes; then add Cu, Sn, rare earth Pr, raise the temperature to 950°C to melt it, and keep it warm for 20 minutes Then add V, Mn, Cr, the temperature rises to 1200°C, and keep it warm for 30 minutes; then add rare earth Er, raise the temperature to 1450°C, stir for 10 minutes, and keep it warm for 30 minutes; cool down to 735°C, and then melt the above alloy Refining in the furnace; adding refining agent to the alloy melt, stirring evenly, and then standing and keeping warm for 30 minutes. After refining, remove slag, let it stand still, and adjust the temperature to 660°C. The alloy liquid is poured out of the furnace, and after degassing and slag removal, it enters the casting machine for casting. The speed of the casting machine is controlled at 2.5m / min, and the aluminum alloy casting is obtained. Ingot, the composition of the ingot ...

Embodiment 2

[0044] (1) Put the aluminum ingot into the furnace, heat it to 750°C to melt it, raise the temperature to 850°C, and keep it for 30 minutes; then add Cu, Sn, rare earth Pr, raise the temperature to 1050°C to melt it, and keep it warm for 20 minutes Then add V, Mn, Cr, the temperature rises to 1300°C, and keep it warm for 30 minutes; then add rare earth Er, raise the temperature to 1550°C, stir for 10 minutes, and keep it warm for 30 minutes; drop the temperature to 740°C, and then melt the above alloy Refining in the furnace; adding refining agent to the alloy melt, stirring evenly, and then standing and keeping warm for 30 minutes. After refining, remove slag, let it stand still, and adjust the temperature to 660°C. The alloy liquid is poured out of the furnace, and after degassing and slag removal, it enters the casting machine for casting. The speed of the casting machine is controlled at 3.5m / min, and the aluminum alloy casting is obtained. Ingot, the composition of the in...

Embodiment 3

[0048] (1) Put the aluminum ingot into the melting furnace, heat it to 730°C to melt it, raise the temperature to 835°C, and keep it for 30 minutes; then add Cu, Sn, rare earth Pr, raise the temperature to 1000°C to melt it, and keep it warm for 20 minutes Then add V, Mn, Cr, the temperature rises to 1250°C, and keep it warm for 30 minutes; then add rare earth Er, raise the temperature to 1500°C, stir for 10 minutes, and keep it warm for 30 minutes; drop the temperature to 738°C, and then melt the above alloy Refining in the furnace; adding refining agent to the alloy melt, stirring evenly, and then standing and keeping warm for 30 minutes. After refining, remove slag, let it stand still, and adjust the temperature to 660°C. The alloy liquid is poured out of the furnace, and after degassing and slag removal, it enters the casting machine for casting. The speed of the casting machine is controlled at 3.0m / min, and the aluminum alloy casting is obtained. Ingot, the composition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com