Liquid-crystal display

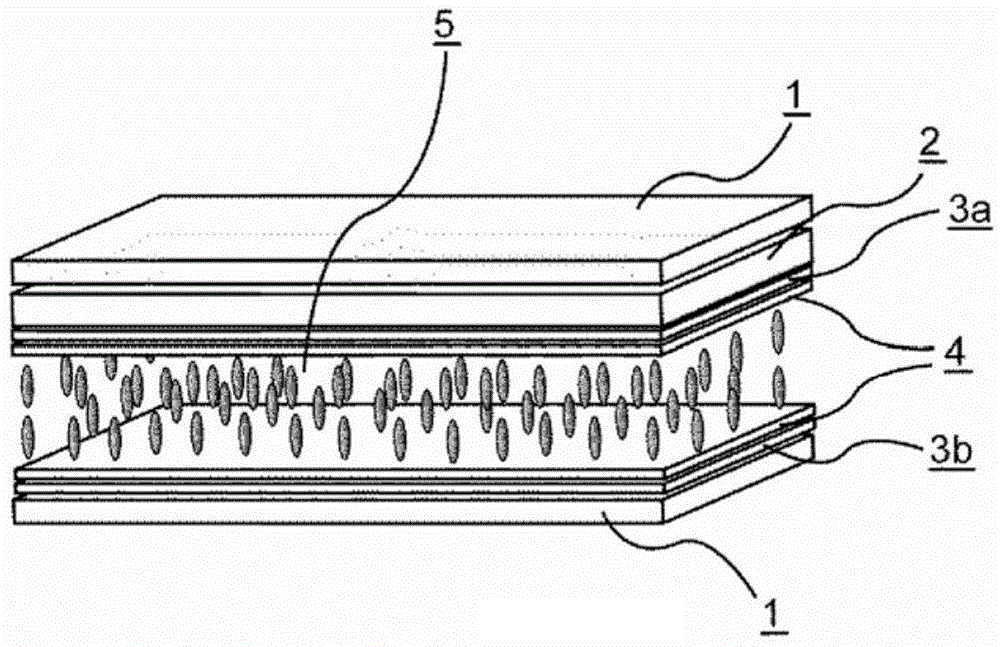

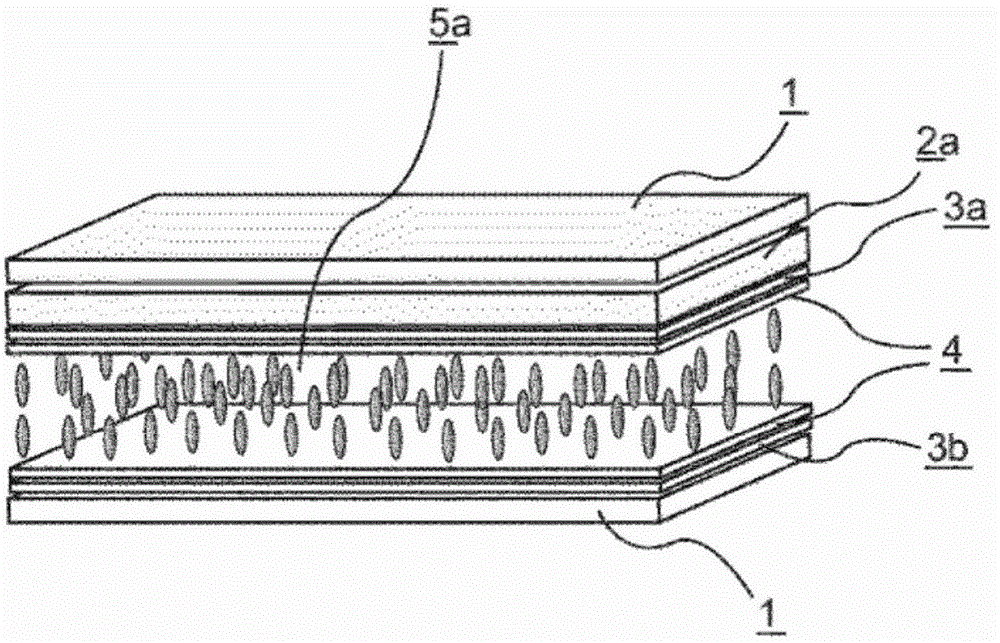

A technology of liquid crystal display device and liquid crystal composition, which is applied in the directions of liquid crystal materials, optics, instruments, etc., can solve problems such as uneven orientation, burns, and white space, and achieve the effect of preventing reduction and white space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0219] Hereinafter, although an Example is given and some best modes of this invention are described in detail, this invention is not limited to these Examples. In addition, "%" in the composition of a following Example and a comparative example shows "mass %".

[0220] In the examples, the characteristics measured are as follows.

[0221] T ni : Nematic phase - isotropic liquid phase transition temperature (°C)

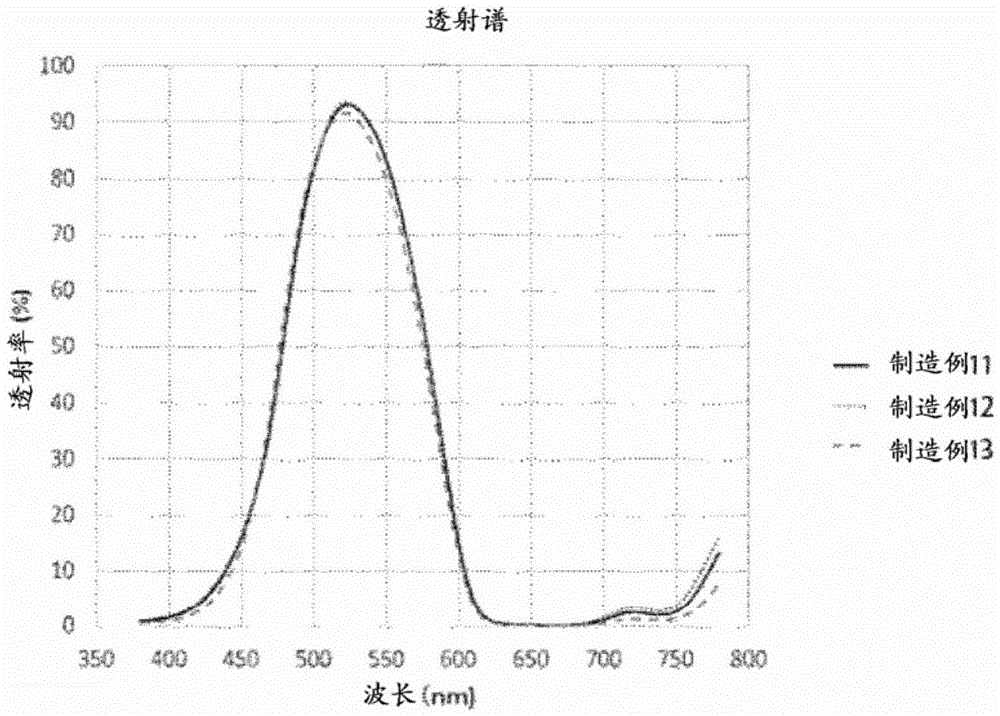

[0222] Δn: Refractive index anisotropy at 25°C

[0223] Δε: Dielectric constant anisotropy at 25°C

[0224] η: Viscosity at 20°C (mPa·s)

[0225] gamma 1 : Rotational viscosity at 25°C (mPa·s)

[0226] d gap : Gap between the first substrate and the second substrate of the unit (μm)

[0227] VHR: Voltage retention rate at 70°C (%)

[0228] (The ratio of the measured voltage to the initial applied voltage when the liquid crystal composition is injected into a cell with a cell thickness of 3.5 μm and measured under the conditions of an applied voltage of 5 V, ...

Synthetic example 1

[0255] Synthesis of Copolymer a

[0256] Keep 100 parts of xylene at 80°C in a nitrogen stream, and dropwise add 68 parts of ethyl methacrylate, 29 parts of 2-ethylhexyl methacrylate, 3 parts of mercaptoacetic acid and polymerization initiator over 4 hours while stirring. Agent (“PERBUTYL (registered trademark) O” [active ingredient tert-butyl peroxy-2-ethylhexanoate, manufactured by NOF Co., Ltd.]) 0.2 parts. After completion of the dropwise addition, 0.5 parts of "PERBUTYL (registered trademark) O" was added every 4 hours, and it stirred at 80 degreeC for 12 hours. After the reaction was completed, xylene was added to adjust the non-volatile content to obtain a xylene solution of the copolymer a having a non-volatile content of 50%.

Synthetic example 2

[0257] Synthesis of Copolymer b

[0258] Keep 100 parts of xylene at 80°C in a nitrogen stream, and dropwise add 66 parts of ethyl methacrylate, 28 parts of 2-ethylhexyl methacrylate, 6 parts of mercaptoacetic acid and polymerization initiator over 4 hours while stirring. Agent (“PERBUTYL (registered trademark) O” [active ingredient tert-butyl peroxy-2-ethylhexanoate, manufactured by NOF Co., Ltd.]) 0.3 parts. After completion of dropping, 0.5 parts of "PERBUTYL (registered trademark) O" was added every 4 hours, and it stirred at 80 degreeC for 12 hours. After completion of the reaction, an appropriate amount of xylene was added to adjust the non-volatile content to obtain a xylene solution of copolymer b having a non-volatile content of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com