Liquid crystal display device

一种液晶显示装置、液晶组合物的技术,应用在液晶材料、仪器、化学仪器和方法等方向,能够解决取向不均、电压保持率离子密度增加、白斑等问题,达到防止白斑、防止降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

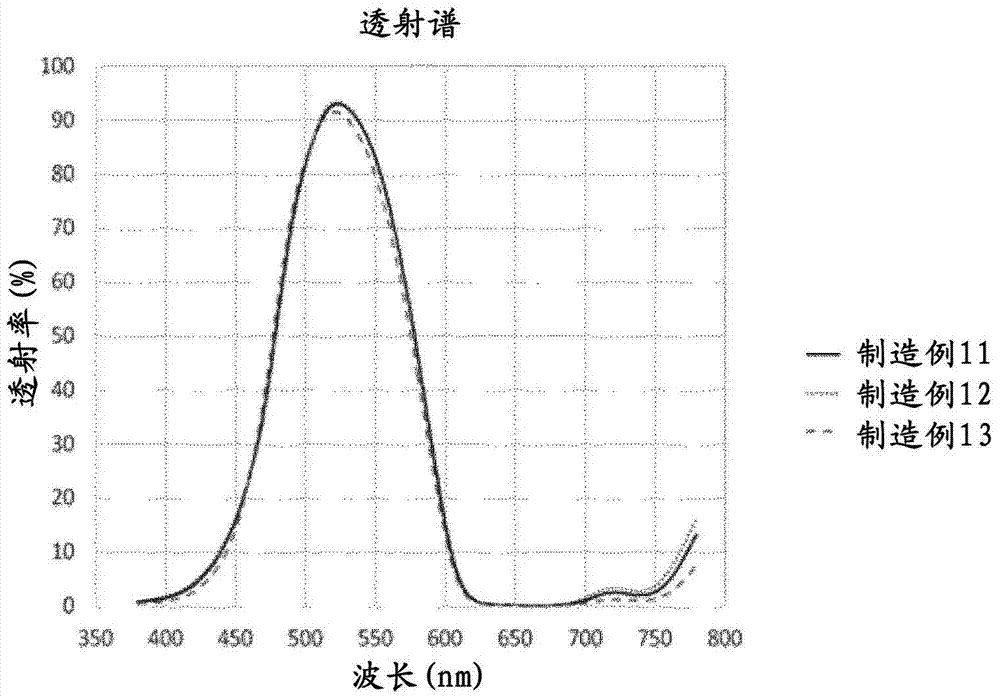

[0214] The following examples are given to further describe the present invention in detail, but the present invention is not limited to these examples. In addition, "%" in the composition of a following Example and a comparative example means "mass %".

[0215] In the examples, the characteristics measured are as follows.

[0216] T ni : Nematic-isotropic liquid phase transition temperature (°C)

[0217] Δn: Refractive index anisotropy at 25°C

[0218] Δε: Dielectric constant anisotropy at 25°C

[0219] η: Viscosity at 20°C (mPa·s)

[0220] γ1: rotational viscosity at 25°C (mPa·s)

[0221] VHR: Voltage retention rate at 70°C (%)

[0222] (A liquid crystal composition is injected into a cell with a cell thickness of 3.5 μm, and the ratio of the measured voltage to the initial applied voltage when measured under the conditions of applying 5 V, a frame time of 200 ms, and a pulse width of 64 μs is expressed in %)

[0223] ID: ion density at 70°C (pC / cm 2 )

[0224] (Ion...

Synthetic example 1

[0240] Synthesis of Copolymer a

[0241] 100 parts of xylene was kept at 80°C in a nitrogen stream, and while stirring, 68 parts of ethyl methacrylate, 29 parts of 2-ethylhexyl methacrylate, 3 parts of thioglycolic acid, and a polymerization initiator ("PERBUTYL (registered trademark) O" [active ingredient tert-butyl peroxy 2-ethylhexanoate, manufactured by NOF Co., Ltd.]) 0.2 parts of the mixture was dripped over 4 hours. After completion of dripping, 0.5 part of "PERBUTYL (registered trademark) O" was added every 4 hours, and it stirred at 80 degreeC for 12 hours. After completion of the reaction, xylene was added to adjust the non-volatile content to obtain a xylene solution of the copolymer a having a non-volatile content of 50%.

Synthetic example 2

[0242] Synthesis of Copolymer b

[0243] 100 parts of xylene was kept at 80°C in a nitrogen stream, and while stirring, 66 parts of ethyl methacrylate, 28 parts of 2-ethylhexyl methacrylate, 6 parts of thioglycolic acid, and a polymerization initiator ("PERBUTYL (registered trademark) O" [active ingredient tert-butyl peroxy 2-ethylhexanoate, manufactured by NOF Co., Ltd.]) 0.3 parts of the mixture was dripped over 4 hours. After completion of dripping, 0.5 part of "PERBUTYL (registered trademark) O" was added every 4 hours, and it stirred at 80 degreeC for 12 hours. After completion of the reaction, an appropriate amount of xylene was added to adjust the non-volatile content to obtain a xylene solution of the copolymer b having a non-volatile content of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com