Liquid crystal display device

A technology of liquid crystal display device and liquid crystal layer, applied in liquid crystal materials, instruments, optics, etc., can solve the problems of increased ion density, reduced voltage holding ratio, white spot, etc., and achieves the effect of preventing white spot and preventing reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

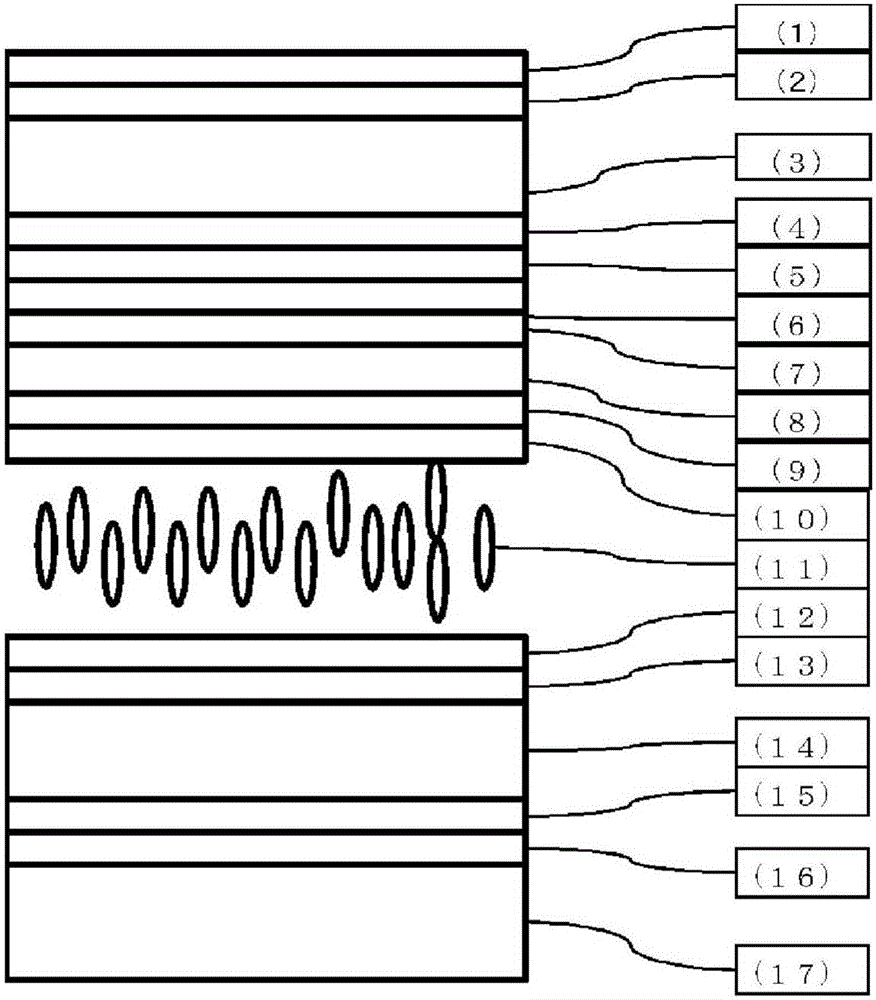

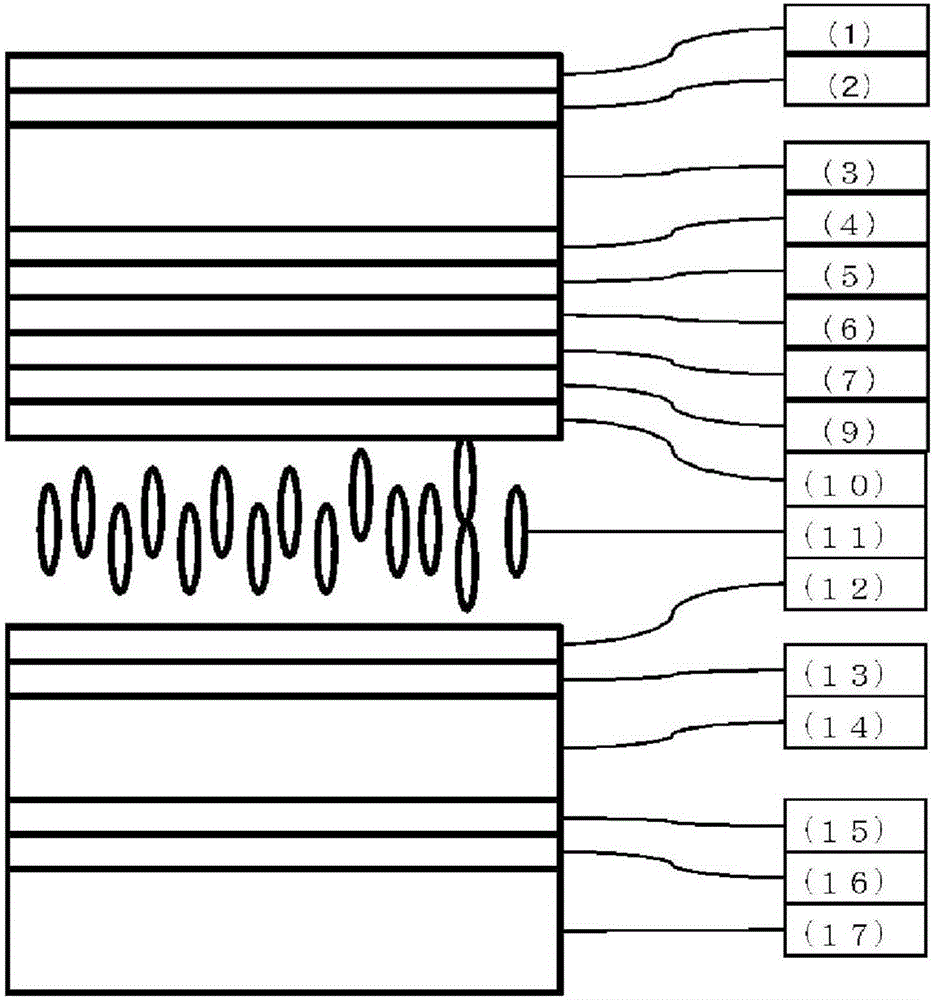

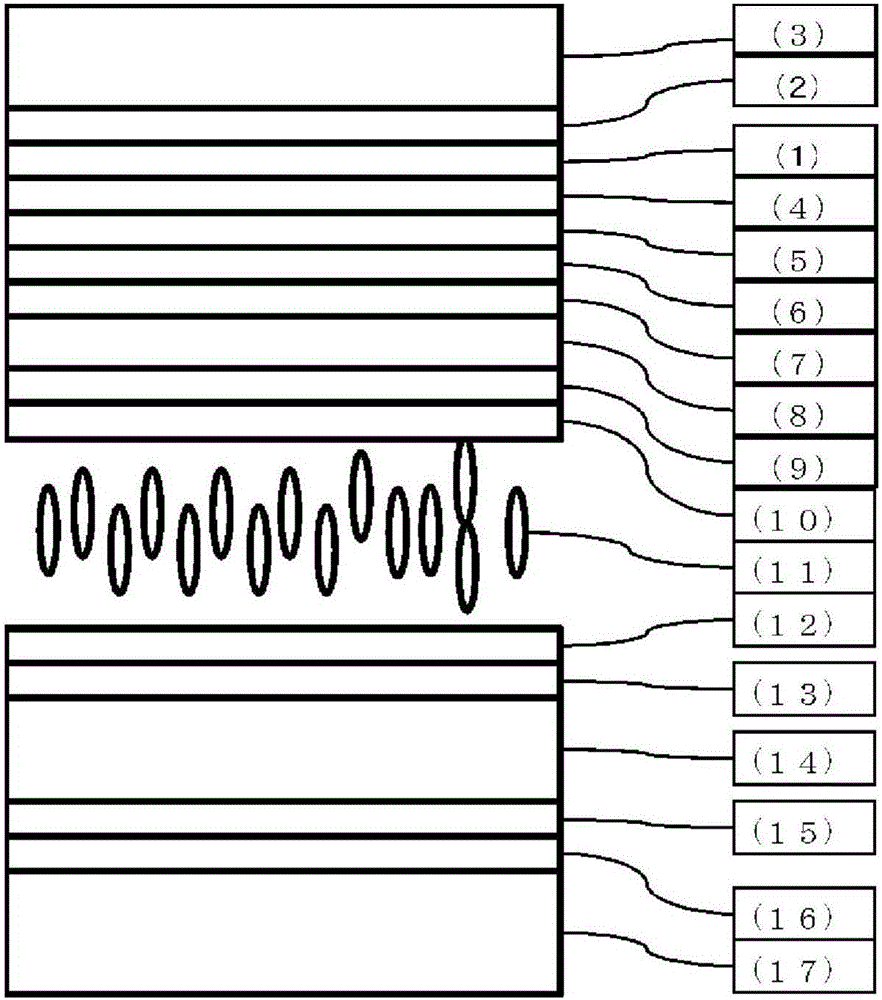

[0563] For the first translucent substrate (3), after the color filter layer (4) is installed, a horizontal alignment film (6) is formed and subjected to weak rubbing treatment. On the rubbed horizontal alignment film (6), use a spin coater to coat polymerizable liquid crystal composition 1, dry it at 80°C for 2 minutes, cool it at room temperature, and irradiate it with a high-pressure mercury lamp at 500mJ / cm 2 Ultraviolet light to make the first retardation layer (7) of the positive type A plate. Use a spin coater to coat the polymerizable liquid crystal composition 2 on the retardation layer, dry it at 80°C for 2 minutes, cool it at room temperature, and irradiate it with a high-pressure mercury lamp at 500mJ / cm 2 The ultraviolet light of making the second retardation layer (8) of negative type C plate. The transparent electrode layer (9) is vapor-deposited on the first retardation layer (7) and the second retardation layer (8) to form an alignment film (10). For the sec...

Embodiment 5~12

[0574] Except having used the liquid crystal composition and polymerizable liquid crystal composition shown below, the liquid crystal display devices of Examples 5-12 were produced similarly to Example 1, and the VHR and ID were measured. Moreover, the burn-in evaluation of this liquid crystal display device was performed. The results are shown in the table below.

[0575] [Table 7]

[0576]

[0577] [Table 8]

[0578]

[0579] [Table 9]

[0580]

[0581] The liquid crystal display devices of Examples 5 to 12 can realize high VHR and small ID. Also, in the burn-in evaluation, there was no image sticking, or even if there was, it was very small, which was at an allowable level.

Embodiment 13~24

[0583] Except having used the liquid crystal composition and polymerizable liquid crystal composition shown below, the liquid crystal display devices of Examples 13-24 were produced similarly to Example 1, and the VHR and ID were measured. Moreover, the burn-in evaluation of this liquid crystal display device was performed. The results are shown in the table below.

[0584] [Table 10]

[0585]

[0586] [Table 11]

[0587]

[0588] [Table 12]

[0589]

[0590] [Table 13]

[0591]

[0592] The liquid crystal display devices of Examples 13 to 24 can realize high VHR and small ID. Also, in the burn-in evaluation, there was no image sticking, or even if there was, it was very small, which was at an allowable level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com