Core-shell structure positive material based on phase diagram design and design method of core-shell structure positive material

A core-shell structure and design method technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of seldom commercialization, reduced material cycle performance, affected safety performance, etc., and achieve good cycle stability and thermal stability. Safety and safety performance, electrochemical performance improvement, high discharge specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

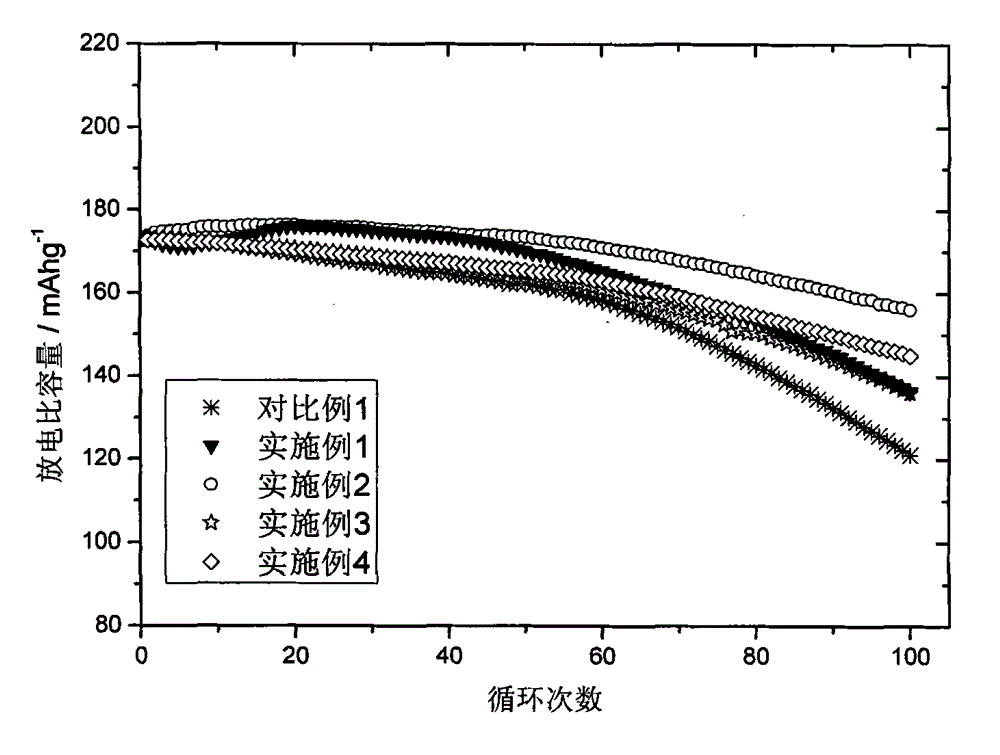

[0041] Prepare 23.5L of 2M salt solution with 11233g of nickel sulfate, 676g of cobalt sulfate and 397g of manganese sulfate. Inject the prepared solution into the reaction kettle at a speed of 1.5L / h at a speed of 400rps, and at the same time inject 4M NaOH solution, pay attention to adjusting the flow rate of the alkali solution, and keep the pH value between 10-11 until the salt solution is completely injected into the reaction In the kettle, continue to inject 26.5L of a salt solution with a concentration of 2M prepared by 4692g of nickel sulfate, 5078g of cobalt sulfate, and 2986g of manganese sulfate into the reactor until the salt solution is completely injected into the reactor, and the precursor preparation reaction is completed. After the reaction, the solid-liquid mixture was separated by centrifugation, washed to neutrality and then dried at 120°C for 24 hours. The dried precursor and lithium carbonate were evenly mixed in a molar ratio of 1:1.05, and then calcined...

Embodiment 2

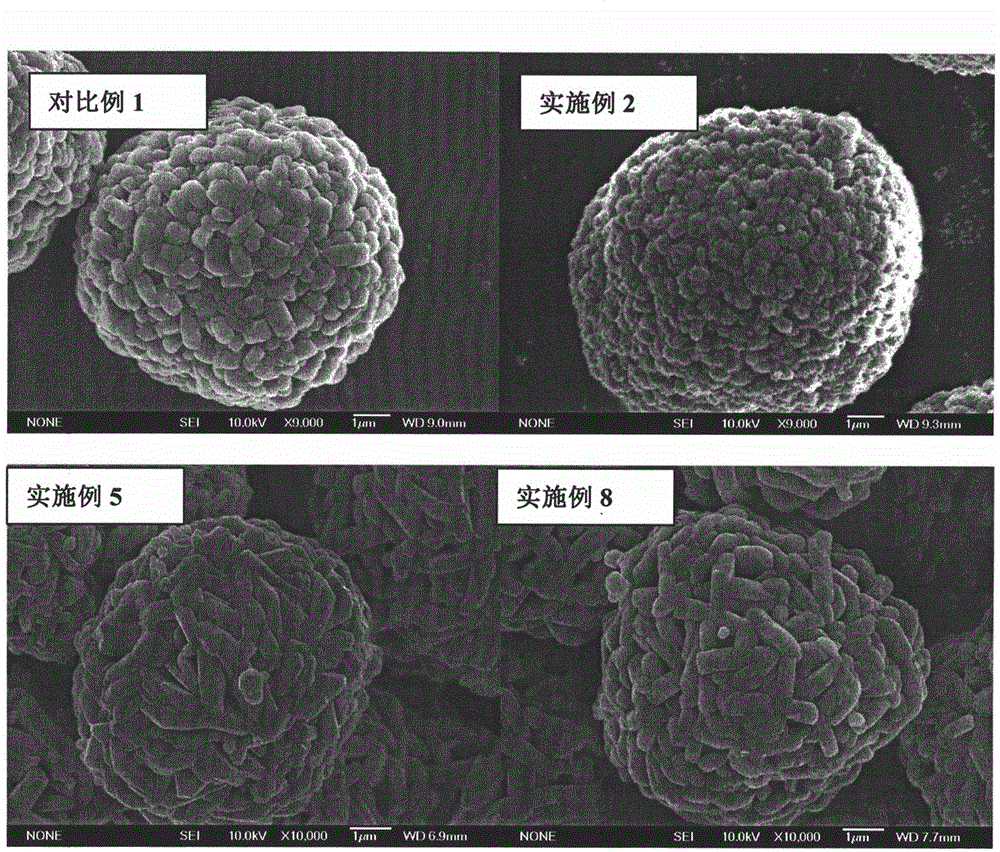

[0043]With 12747g of nickel sulfate, 1724g of cobalt sulfate and 1014g of manganese sulfate, 30L of salt solution with a concentration of 2M was prepared. Inject the prepared solution into the reaction kettle at a speed of 1.5L / h at a speed of 400rps, and at the same time inject 4M NaOH solution, pay attention to adjusting the flow rate of the alkali solution, and keep the pH value between 10-11 until the salt solution is completely injected into the reaction In the kettle, continue to inject 10L of a salt solution with a concentration of 2M prepared by 3540g of nickel sulfate, 3830g of cobalt sulfate, and 2246g of manganese sulfate into the reactor until the salt solution is completely injected into the reactor, and the precursor preparation reaction is completed. After the reaction, the solid-liquid mixture was separated by centrifugation, washed to neutrality and then dried at 120°C for 24 hours. The dried precursor and lithium carbonate were evenly mixed in a molar ratio o...

Embodiment 3

[0045] Prepare 16.7L of 2M salt solution with 7082g of nickel sulfate, 958g of cobalt sulfate and 552g of manganese sulfate. Inject the prepared solution into the reaction kettle at a speed of 1.5L / h at a speed of 400rps, and at the same time inject 4M NaOH solution, pay attention to adjusting the flow rate of the alkali solution, and keep the pH value between 10-11 until the salt solution is completely injected into the reaction In the kettle, continue to pour 8852g of nickel sulfate, 4792g of cobalt sulfate, and 2818g of manganese sulfate to prepare 33.3L of a salt solution with a concentration of 2M into the reactor until the salt solution is completely injected into the reactor, and the precursor preparation reaction is completed. After the reaction, the solid-liquid mixture was separated by centrifugation, washed to neutrality and then dried at 120°C for 24 hours. The dried precursor and lithium carbonate were evenly mixed in a molar ratio of 1:1.05, and then calcined in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com