Noble metal ordered nanostructure array and its preparation method and use

A nanostructure and precious metal technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of time-consuming consumables, complicated production process, product growth, etc., and achieve good consistency and repeatability , The preparation method is simple, and the consistency is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The concrete steps of preparation are:

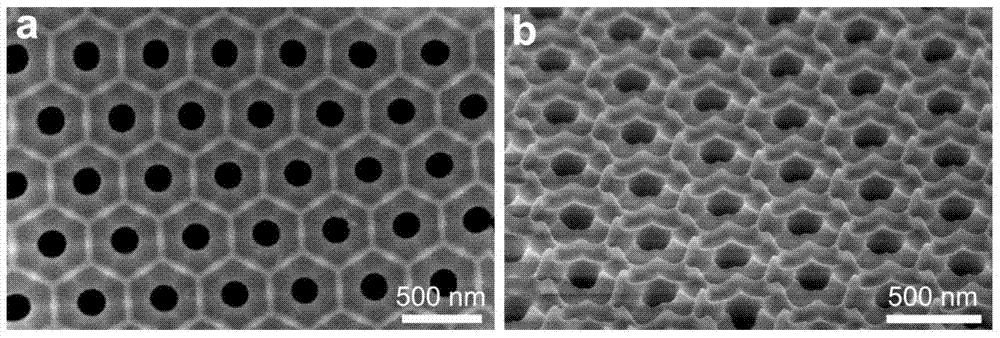

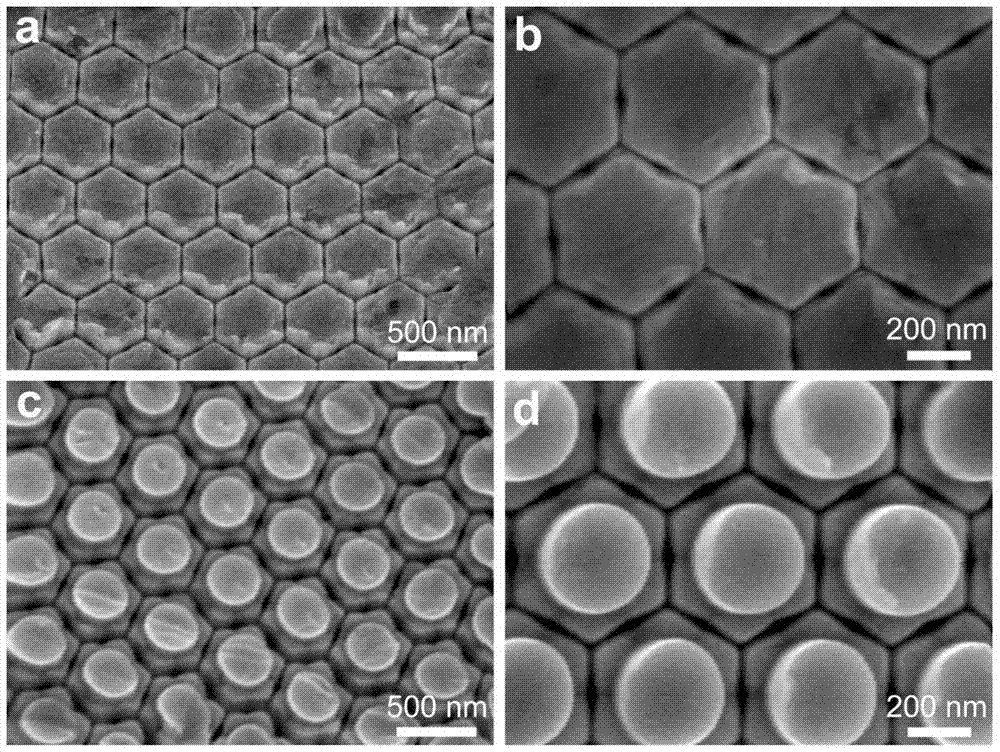

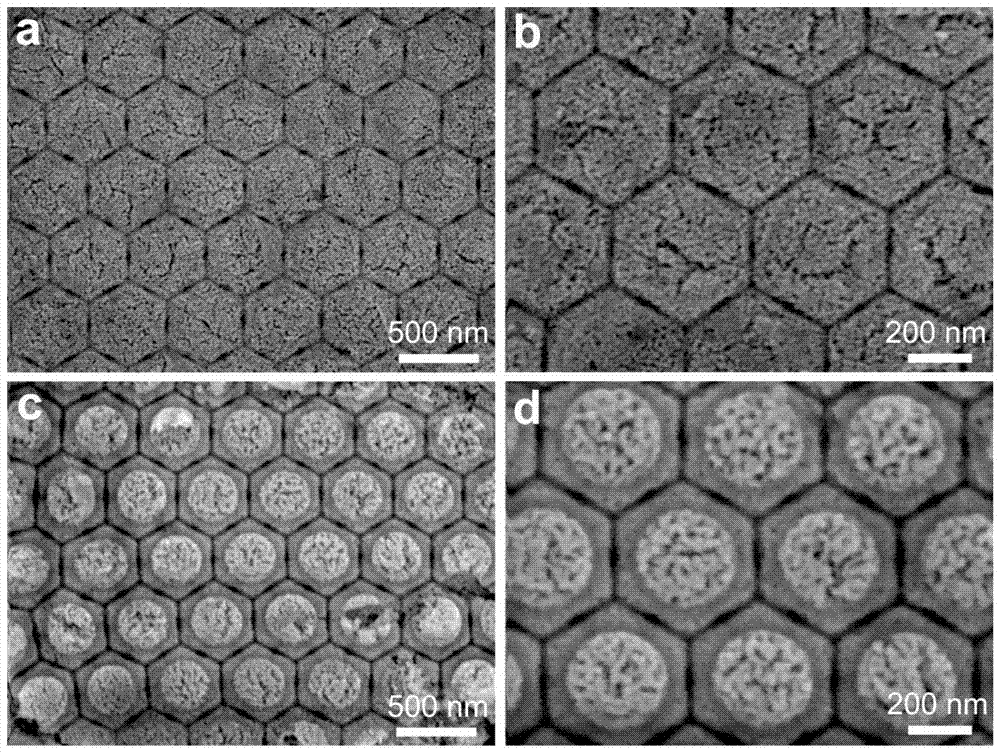

[0051] Step 1: First place the aluminum sheet in -1°C, 1.5wt% phosphoric acid solution, anodize it at 190V DC constant voltage for 4.5h, and then soak it in 55°C phosphochromic acid mixture for 11h. Next, put it again under the same process conditions for the second anodic oxidation for 13 hours, first remove the unoxidized aluminum on the back with a saturated tin chloride solution, and then place it in a 12wt% phosphoric acid solution at 48°C to remove After the barrier layer, the hole was expanded for 5 minutes to obtain a through-hole alumina template with a hole diameter of 160nm, a hole period of 470nm, and a hexagonal concave-convex structure array between the holes; wherein, the hexagonal concave-convex structure is formed by the outer wall of the hole and the surrounding pits, the hole The inner wall is formed between adjacent pits, the pits are all located at the hexagons of the hexagonal concave-convex structure, the t...

Embodiment 2

[0054] The concrete steps of preparation are:

[0055] Step 1: first place the aluminum sheet in 0°C, 1.3wt% phosphoric acid solution, anodize it at 193V DC constant voltage for 4.3h, and then soak it in 58°C phosphoric chromic acid mixture for 10.5h. Next, put it under the same process conditions for the second anodic oxidation for 13.5 hours, remove the unoxidized aluminum on the back with a saturated tin chloride solution, and then place it in an 11wt% phosphoric acid solution at 49°C After removing the barrier layer, the hole was expanded for 10 minutes to obtain a through-hole alumina template with a hole diameter of 215nm, a hole period of 478nm, and an array of hexagonal concave-convex structures between the holes; where the hexagonal concave-convex structure is formed by the outer wall of the hole and the surrounding pits, The inner wall formed between the adjacent pits between the holes is composed of the pits located at the hexagons of the hexagonal concave-convex st...

Embodiment 3

[0058] The concrete steps of preparation are:

[0059] Step 1: first place the aluminum sheet in a 1°C, 1wt% phosphoric acid solution, anodize it at a DC constant voltage of 195V for 4 hours, and then soak it in a phosphochromic acid mixture at 60°C for 10 hours. Then, put it again under the same process conditions for the second anodic oxidation for 14 hours, first remove the unoxidized aluminum on the back with a saturated tin chloride solution, and then place it in a 10wt% phosphoric acid solution at 50°C to remove After the barrier layer, the hole was expanded for 15 minutes to obtain a through-hole alumina template with a hole diameter of 270nm, a hole period of 486nm, and an array of hexagonal concave-convex structures between the holes; wherein, the hexagonal concave-convex structure is formed by the outer wall of the hole and the surrounding pits, the hole The inner wall is formed between the adjacent pits, the pits are all located at the hexagons of the hexagonal conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com