Electrode doped with nano-gold for dye-sensitized solar cell and preparation method thereof

A solar cell and dye sensitization technology, applied in the field of electrodes and their preparation, can solve problems such as difficult large-scale application, increased interface resistance, and electronic difficulties, so as to improve light absorption efficiency, enhance electromagnetic field strength, and reduce large interface The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

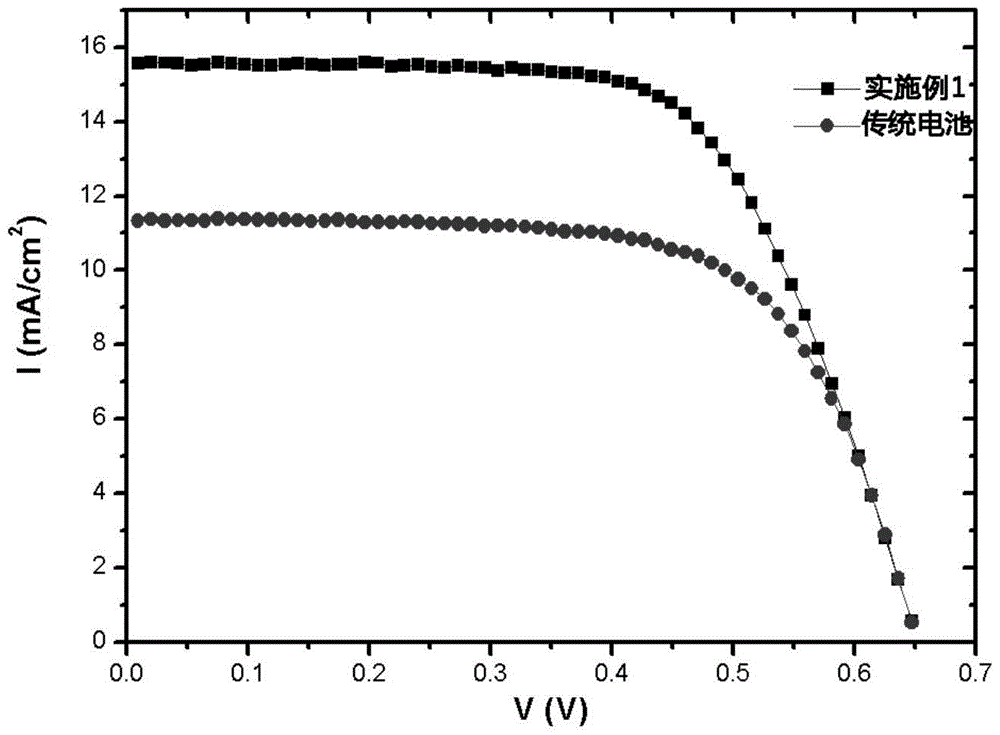

Embodiment 1

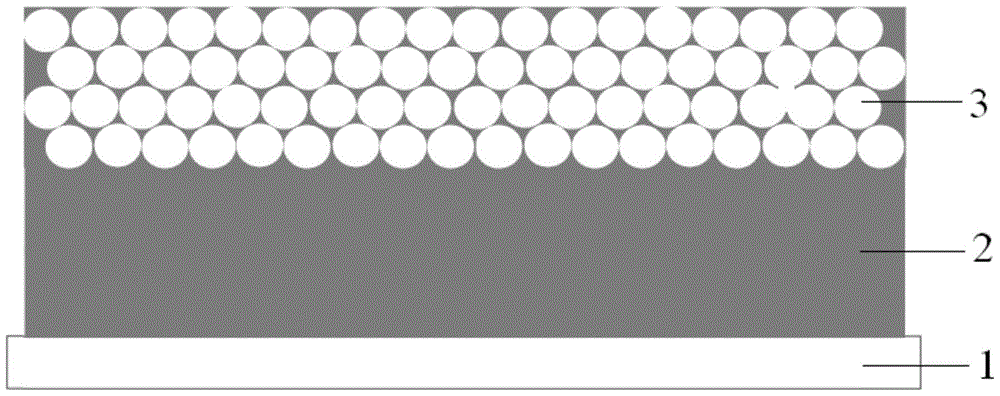

[0032] The preparation method of the electrode doped with nano gold for dye-sensitized solar cells adopts the following steps:

[0033] (1) The FTO conductive glass was cut into 1cm×4cm slides, soaked in piranha solution (3:1H2SO4:30%H2O2) for 24 hours and then washed with deionized water.

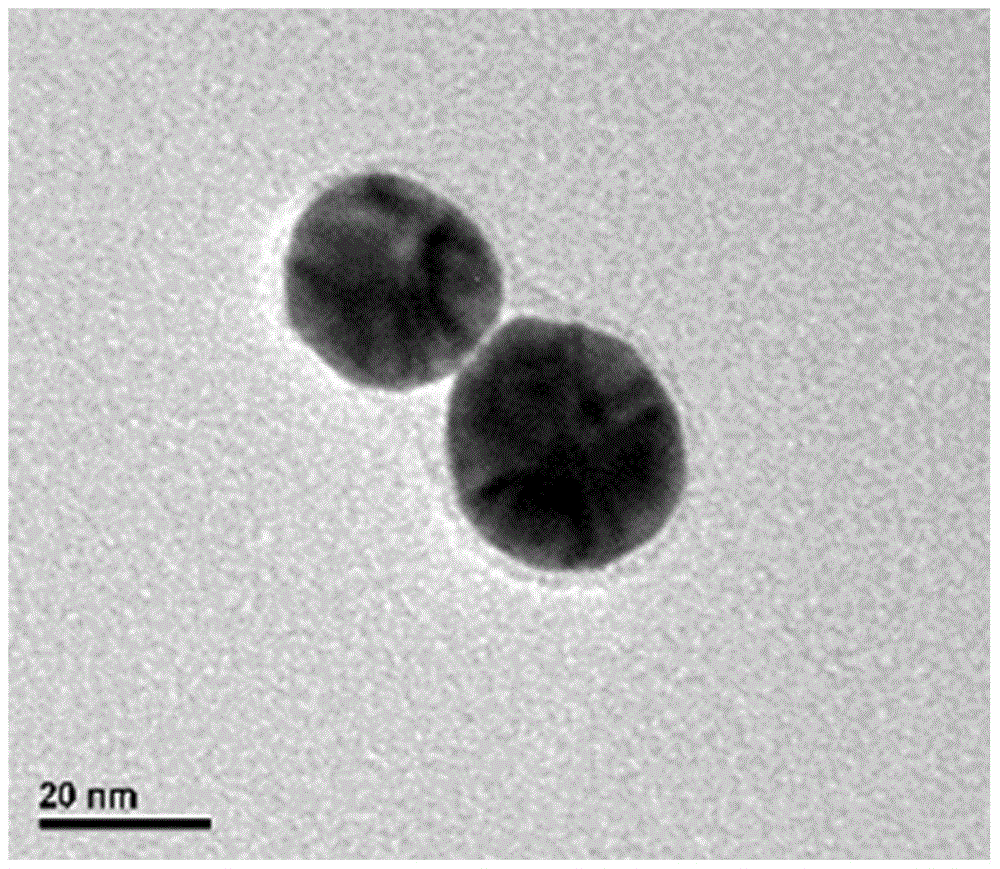

[0034] (2) Concentration is 1000ml of the chloroauric acid aqueous solution of 0.01%wt, boils under magnetic stirring heating, and adds the sodium citrate 10~100ml of concentration 1%wt rapidly, reacts and breaks away from heat source after 1~20 minutes. A nano-gold solution is prepared. After the solution is cooled, add 20 ml of triethoxysilane (APTES) aqueous solution with a concentration of 1.71 μM dropwise to the solution, stir vigorously for 40 minutes, add 40 ml of 0.54% wt sodium silicate aqueous solution, continue to stir for 12 minutes, and let stand Three days later, a solution of gold nanoparticles coated with silicon dioxide was obtained, and the pH value was adjusted to 10-11...

Embodiment 2

[0045] The preparation method of the electrode doped with nano gold for dye-sensitized solar cells adopts the following steps:

[0046] (1) The FTO conductive glass was cut into 1cm×4cm slides, soaked in piranha solution (3:1H2SO4:30%H2O2) for 24 hours and then washed with deionized water.

[0047] (2) Concentration is 1000ml of the chloroauric acid aqueous solution of 0.01%wt, boils under magnetic stirring heating, and adds the sodium citrate 10~100ml of concentration 1%wt rapidly, reacts and breaks away from heat source after 1~20 minutes. A nano-gold solution is prepared. After the solution is cooled, add 20 ml of triethoxysilane (APTES) aqueous solution with a concentration of 1.71 μM dropwise to the solution, stir vigorously for 40 minutes, add 40 ml of 0.54% wt sodium silicate aqueous solution, continue to stir for 12 minutes, and let stand Three days later, a solution of gold nanoparticles coated with silicon dioxide was obtained, and the pH value was adjusted to 10-11...

Embodiment 3

[0057] The preparation method of the electrode doped with nano gold for dye-sensitized solar cells adopts the following steps:

[0058] (1) The FTO conductive glass was cut into 1cm×4cm slides, soaked in piranha solution (3:1H2SO4:30%H2O2) for 24 hours and then washed with deionized water.

[0059] (2) Concentration is 1000ml of the chloroauric acid aqueous solution of 0.01%wt, boils under magnetic stirring heating, and adds the sodium citrate 10~100ml of concentration 1%wt rapidly, reacts and breaks away from heat source after 1~20 minutes. A nano-gold solution is prepared. After the solution is cooled, add 20 ml of triethoxysilane (APTES) aqueous solution with a concentration of 1.71 μM dropwise to the solution, stir vigorously for 40 minutes, add 40 ml of 0.54% wt sodium silicate aqueous solution, continue to stir for 12 minutes, and let stand Three days later, a solution of gold nanoparticles coated with silicon dioxide was obtained, and the pH value was adjusted to 10-11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com