Method of stress sensitivity experiment using artificial fractured carbonate cores

A stress-sensitive, carbonate rock technology, used in the preparation of test samples, measurement devices, suspensions and porous material analysis, etc., can solve the problem that the core hardness cannot meet the stress-sensitive test, etc., to meet the requirements of repeated use. , the effect of strong hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The titration method is used to measure the carbonate rock in the natural core to be 88%, and the carbonate rock in the carbonate rock powder to be 92%. The mixture of carbonate rock powder and quartz sand is prepared, and the ratio of the two is 24:1. Among them, the carbonate rock powder and the quartz sand mesh number are both 300.

[0059] Prepare the dosage of the cement in proportion, and the dosage of medicines required for every 100g of the mixture is: 10g of epoxy resin, 2.1ml of dibutyl phthalate, 0.85ml of ethylenediamine, and 4.05ml of acetone. Fully mix the well-proportioned minerals and cement, let it dry at room temperature for 2 hours, pour it into an artificial core mold, and press it under an axial pressure of 50 MPa for 48 hours. The core was taken out of the mold and dried in a thermostat at 90°C for 12 hours.

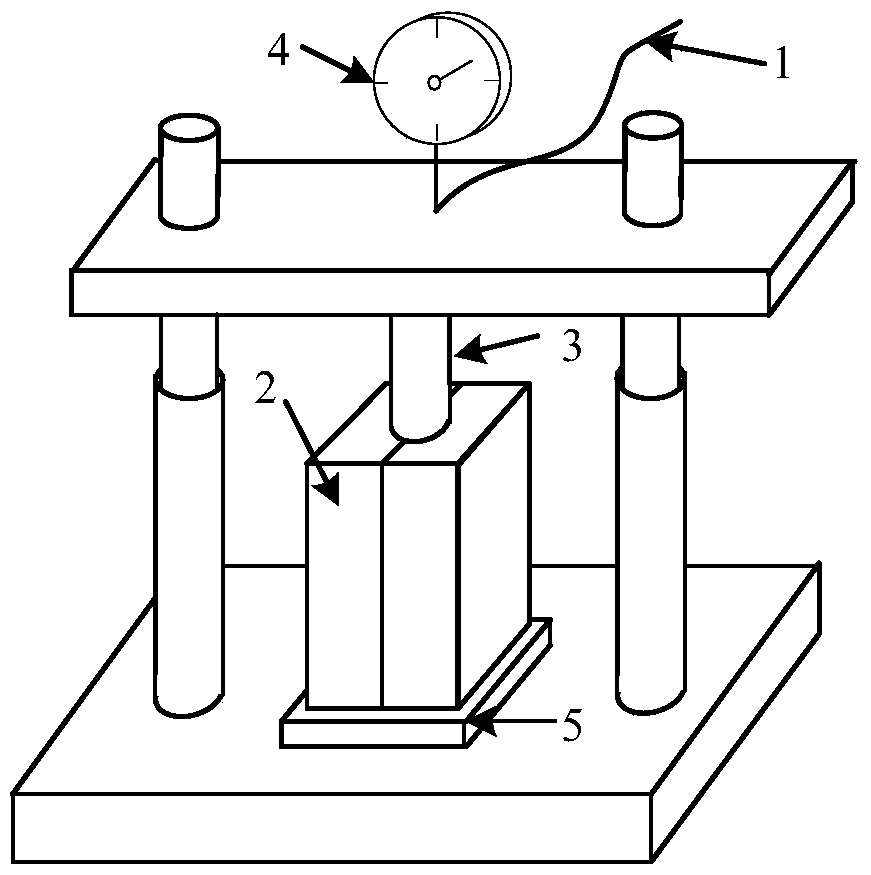

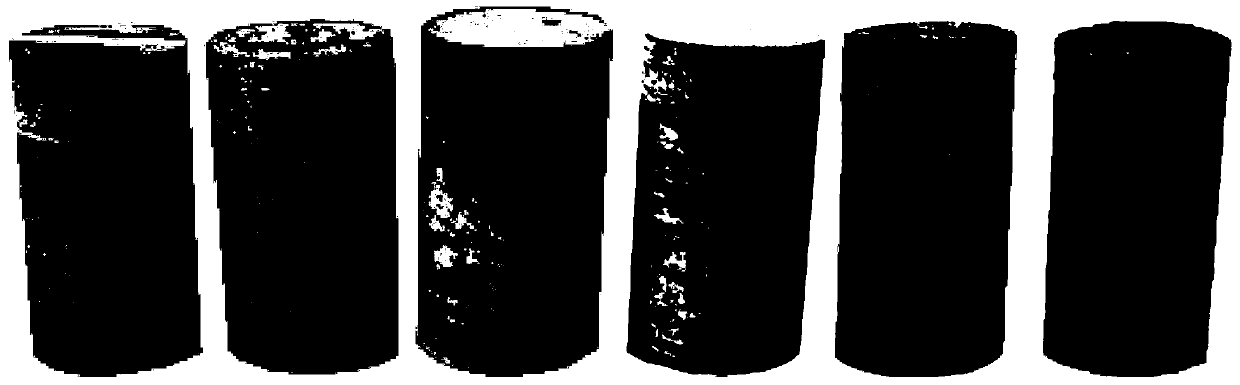

[0060] According to the above steps, 6 matrix cores were made, and 4 of them were pressed image 3 The device shown performs fracture crea...

Embodiment 2

[0065] Prepare a mixture of carbonate rock powder and quartz sand at a ratio of 24:1. Among them, the carbonate rock powder and the quartz sand mesh number are both 300. Prepare the amount of cement in proportion, and the amount of medicine required for every 100g of the mixture is: 10g of epoxy resin, 2.1ml of dibutyl phthalate, 0.85ml of ethylenediamine, and 4.05ml of acetone; The mixture was thoroughly mixed, left to air at room temperature for 2 hours, poured into an artificial core mold, and pressed under an axial pressure of 50 MPa for 48 hours. The core was taken out from the mold and dried in a constant temperature oven at 90°C for 12 hours.

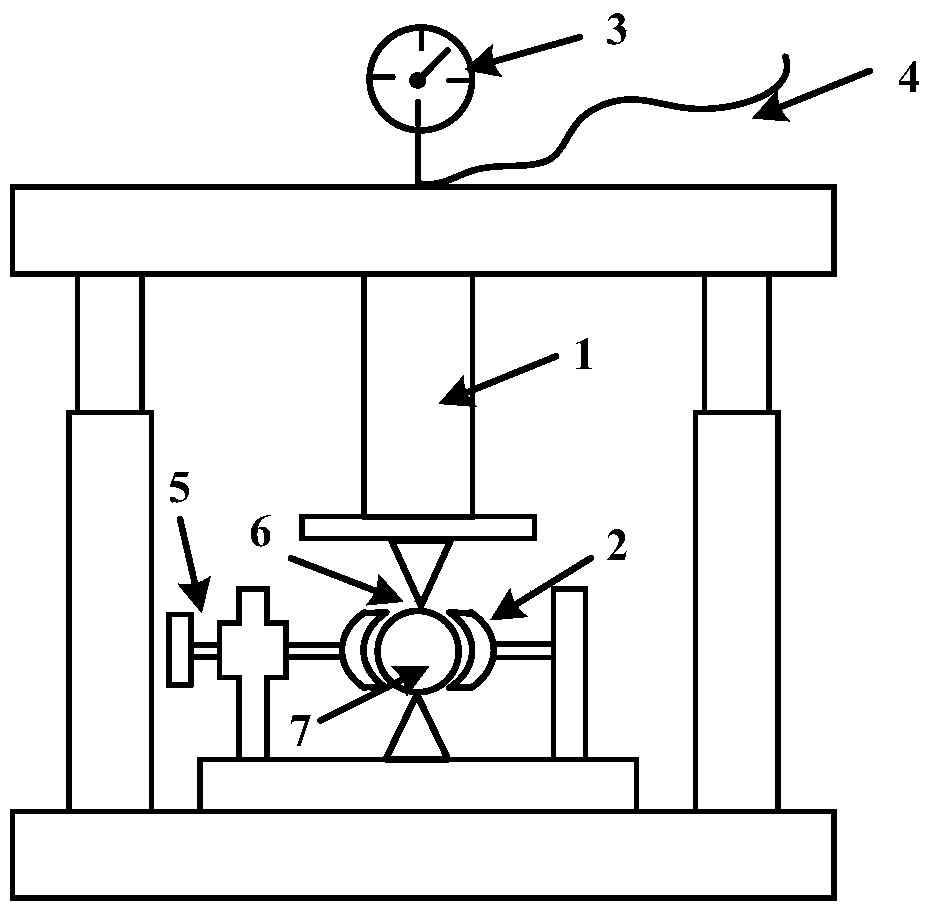

[0066] Put the matrix core into the stress-sensitivity experiment device, and record the permeability values sequentially under confining pressures of 3MPa, 10MPa, 20MPa, 30MPa, and 40MPa; after the experiment is completed, take out the core and put it in image 3 Seam making device shown. After the fractures penetrating the...

Embodiment 3

[0074] In order to verify the simulation effect of the artificial core on the natural core, the stress-sensitivity test data of the unfilled fracture core constructed by the present invention and the natural unfilled fracture core are compared. Natural core data references: Experimental study on stress sensitivity of carbonate rock cores [J], Natural Gas Industry, 2002, 22 (Supplement): 114-117. Depend on Figure 7 It can be seen that the artificial unfilled fractured core is consistent with the stress sensitivity change law of the natural unfilled fractured core.

[0075] For unfilled cores, due to the strong stress sensitivity of the fracture permeability, when the effective stress is small, the fracture permeability decreases sharply, which mainly reflects the stress sensitivity of the fracture. As the effective confining pressure increases and the fractures close, the stress sensitivity of the permeability of the matrix gradually appears. Figure 8 and Figure 9 Schemat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com