High-water-resistance backboard for solar battery assembly

A solar cell and module technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of water blocking backplane safety performance not guaranteed, components short circuit, etc., and achieve the effect of good weather resistance and low water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

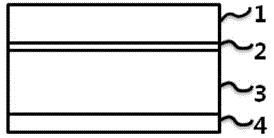

Image

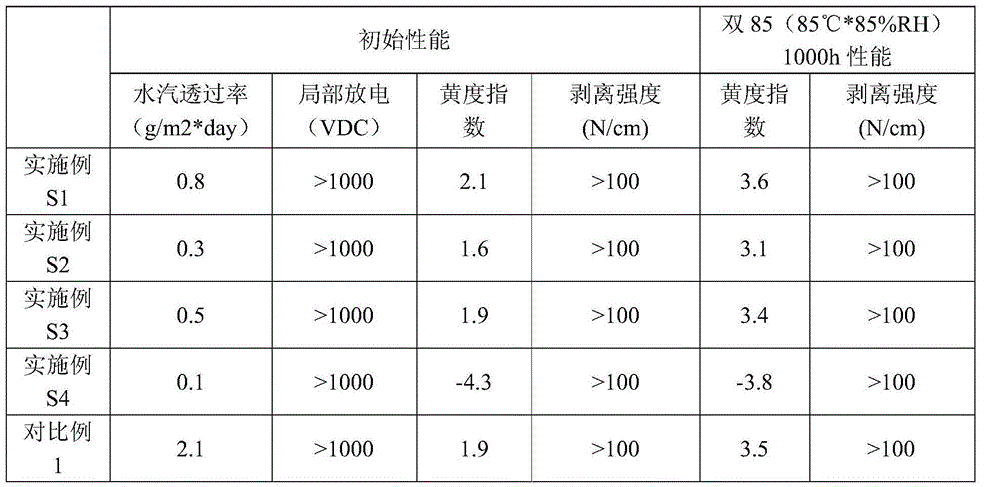

Examples

Embodiment 1

[0036] The formula of the olefin copolymer layer is as follows: in parts by mass, 100 parts of VA content is 30% ethylene-vinyl acetate copolymer (U.S. DuPont), add 1 part of super absorbent resin AQUA KEEP SA60S (Sumitomo Corporation of Japan), 0.2 parts of cross-linking agent tert-butyl peroxyisopropyl carbonate (Bailingwei Technology Co., Ltd.), 0.2 parts of antioxidant tris(2,4,-di-tert-butylphenyl) phosphite (Tianda Tianhai Technology Development Co., Ltd. company), 0.1 part of UV absorber 2-hydroxy-4-n-octyloxybenzophenone (Nanjing Zhonghesheng Technology Co., Ltd.), 0.5 part of light stabilizer sebacic acid bis-2,2,6,6- Tetramethylpiperidinol ester (Shanghai Yanjia Plastic Chemical Co., Ltd.), and mix well. The mixture was blended and extruded in an extruder, and the temperature was controlled at 90°C. After extrusion, it was cast, cooled, cut, and rolled to obtain an inner film layer with a thickness of 500 μm.

[0037]The formula of the fluorine-containing resin weat...

Embodiment 2

[0041] The formula of the olefin copolymer bonding layer is as follows: in parts by mass, 100 parts of VA content is 20% ethylene-vinyl acetate copolymer (U.S. DuPont), add 10 parts of super absorbent resin polyvinyl alcohol (Nippon Synthetic Chemical Co., Ltd. ), 0.5 parts of cross-linking agent tert-butyl peroxyisopropyl carbonate (Bailingwei Technology Co., Ltd.), 1.2 parts of antioxidant 2,2'-methylene-bis-(4-ethyl-6-tert-butyl Phenol) (Shanghai Ruiding Chemical Company), 0.1 part of UV absorber 2,2'-dihydroxy-4,4'-dimethoxybenzophenone (Nanjing Zhonghesheng Technology Co., Ltd.), 0.1 part of hindered amine Light stabilizer bis-1-decaneoxy-2,2,6,6-tetramethylpiperidin-4-ol sebacate and mix well. The mixture was blended and extruded in an extruder, and the temperature was controlled at 90°C. After extrusion, it was cast, cooled, cut, and rolled to obtain an inner film layer with a thickness of 200 μm.

[0042] The formula of the fluorine-containing resin weather-resistant ...

Embodiment 3

[0046] The formulation of the olefin copolymer bonding layer is as follows: in parts by mass, in 100 parts of ethylene-octene copolymer (DuPont, USA), add 5 parts of super absorbent resin SA60N (Sumitomo, Japan), 5 parts of crosslinking agent 1- Bis(tert-butyl peroxide)-3,3,5-trimethylcyclohexane (Bailingwei Technology Co., Ltd.), 2 parts of antioxidant 2,2'-methylene-bis-(4-ethyl- 6-tert-butylphenol) (Shanghai Ruiding Chemical Company), 0.5 parts of UV absorber 2,2'-dihydroxy-4,4'-dimethoxybenzophenone (Nanjing Zhonghesheng Technology Co., Ltd.) , 0.5 parts of hindered amine light stabilizer 3,5-di-tert-butyl-4-hydroxy-hexadecyl benzoate and mix well. The mixture was blended and extruded in an extruder, and the temperature was controlled at 120°C. After extrusion, it was cast, cooled, cut, and rolled to obtain an inner film layer with a thickness of 300 μm.

[0047] The formula of fluorine-containing resin weather-resistant layer is as follows: in parts by mass, in 100 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com