A twin-roll thin strip continuous casting fine-grain oriented silicon steel thin strip blank and its manufacturing method

A technology of twin-roll thin strip continuous casting and oriented silicon steel, which is applied in the field of electrical steel manufacturing, can solve the problems of difficult control of local contact state, narrow temperature control range, and uneven structure of thin strip billet, so as to achieve simple manufacturing process and suppress grain The effect of growing up and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition of fine-grain oriented silicon steel strip cast by twin-roll strip continuous casting is C 0.06%, Si 3.1%, Mn 0.20%, S 0.020%, Als 0.03%, N 0.009%, Ti 0.05%, O<0.004 %, P<0.01%, the balance is Fe; the average grain size is only 35mm; the thickness is 3.0mm;

[0028] The manufacturing method proceeds in the following steps:

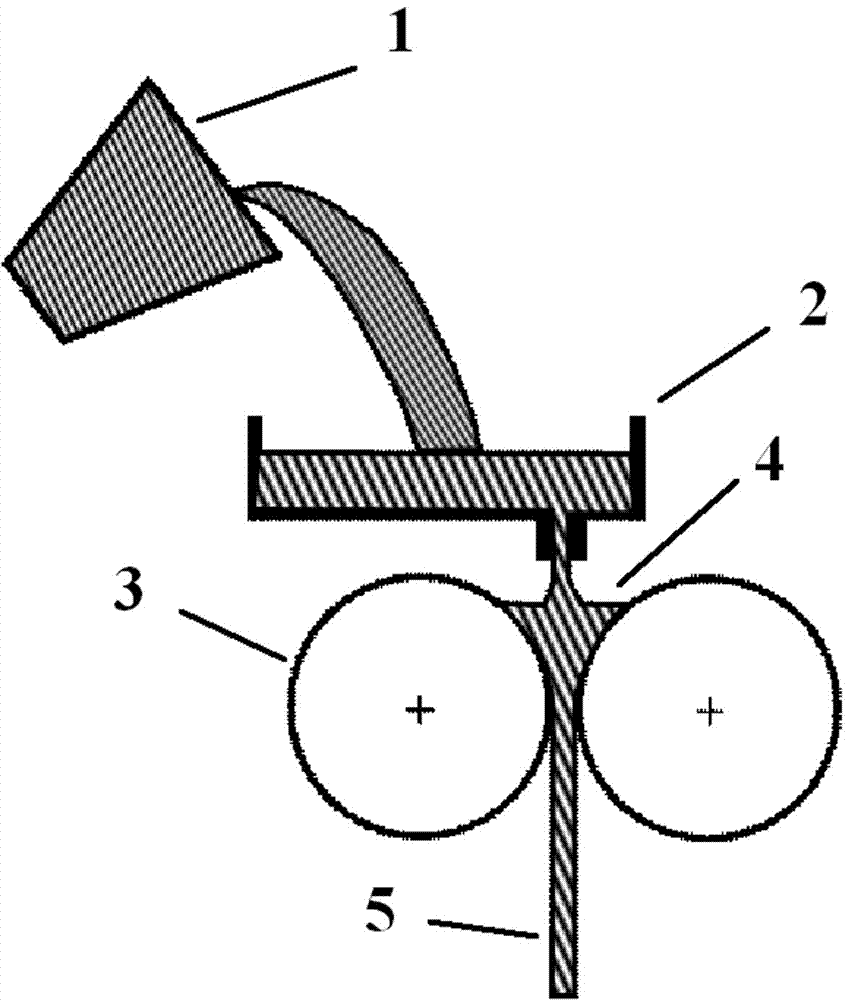

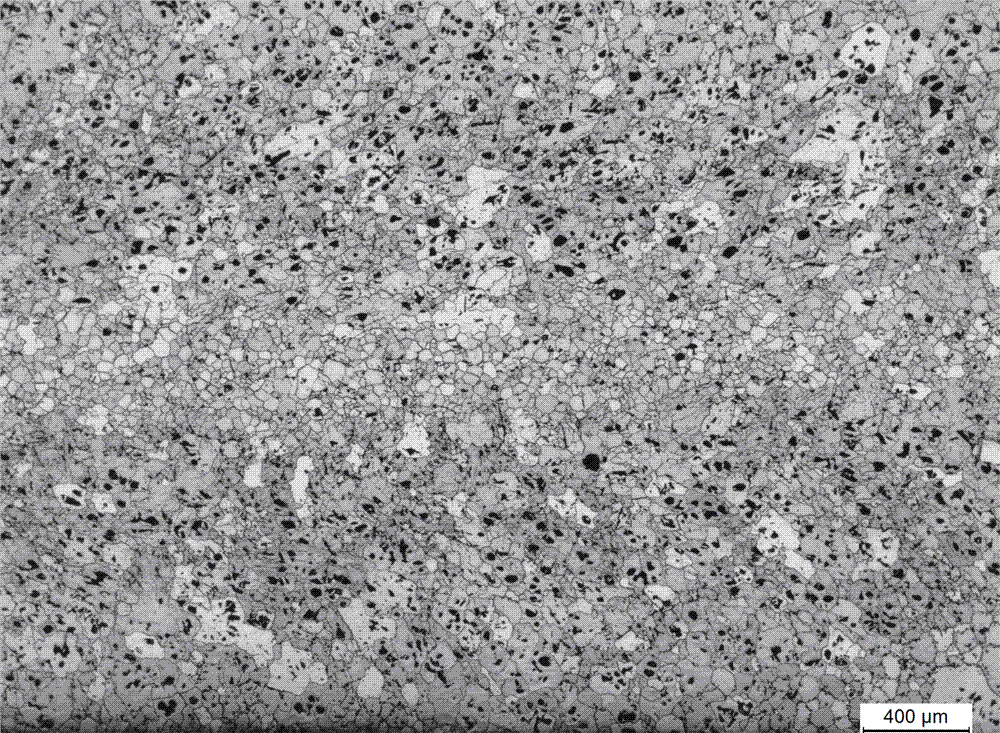

[0029] The molten steel is smelted according to the above composition. The smelted molten steel is poured from the ladle through the tundish into the cavity composed of two crystallization rollers and two side sealing plates to form a molten pool. The upper surface superheat of the molten pool is controlled at 40°C. The molten steel is exported at a speed of 20m / min along with the rotation of the crystallization roller; the obtained twin-roll strip continuous casting fine-grain oriented silicon steel thin strip has a fine and uniform solidification structure, such as figure 2 shown;

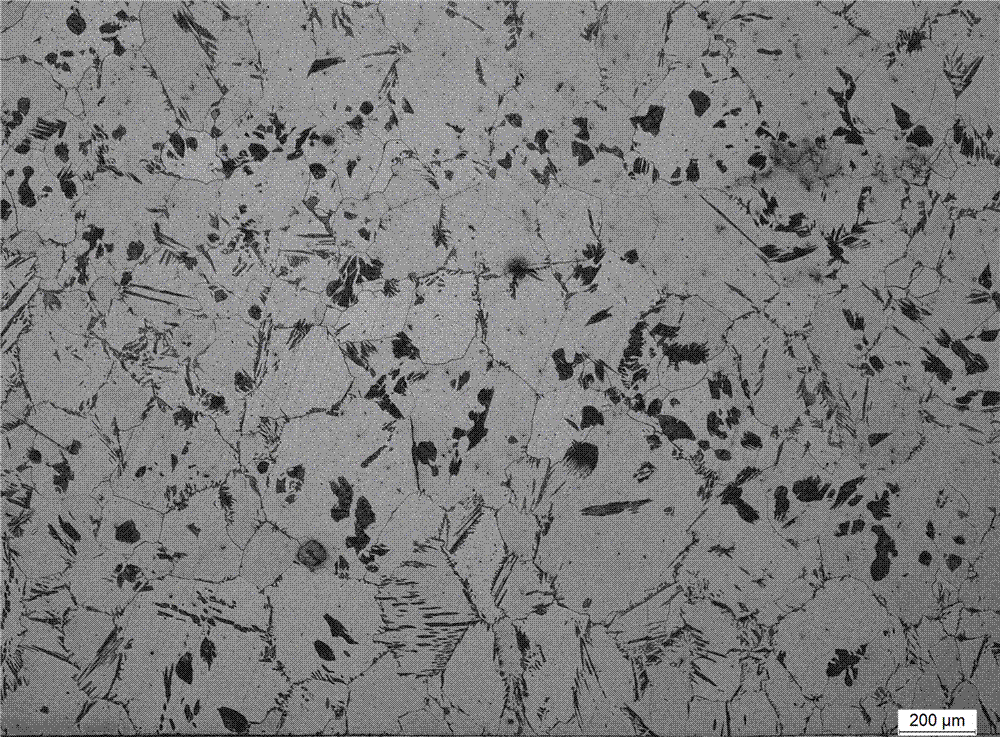

[0030] Molten steel with different components ...

Embodiment 2

[0032] The composition of fine-grain oriented silicon steel thin strip cast by twin-roll strip continuous casting is C 0.01%, Si 2.8%, Mn 0.05%, S 0.015%, Als 0.05%, N 0.01%, Ti 0.01%, Cu 0.3% by mass percentage , Sn 0.1%, O<0.004%, P<0.01%, the balance is Fe; the average grain size is 20mm, and the thickness is 1.0mm;

[0033] The manufacturing method is the same as that in Example 1, except that the superheating degree of the upper surface is 10°C, and the lead-out speed is 20 m / min; the obtained twin-roll thin strip continuous casting fine-grain-oriented silicon steel thin strip has a fine and uniform solidification structure;

[0034] Molten steel with different components was used for comparative experiments as above, and the components were C 0.05%, Si 2.9%, Mn 0.02%, S 0.06%, Als 0.03%, N 0.002%, O<0.004%, P<0.01% according to the mass percentage , the balance is Fe; the average grain size is 420mm; the thin strip blank has a coarse and uneven solidification structure. ...

Embodiment 3

[0036]The composition of fine-grain oriented silicon steel thin strip cast by twin-roll strip continuous casting is as follows: C 0.08%, Si 3.4%, Mn 0.30%, S 0.04%, Als 0.005%, N 0.003%, Ti 0.5%, Cu 0.6% %, Sn 0.2%, O<0.004%, P<0.01%, the balance is Fe; the average grain size is only 45mm, and the thickness is 5.0mm;

[0037] The manufacturing method is the same as that of Example 1, except that: the upper surface superheat is 70°C, and the lead-out speed is 60m / min; the obtained twin-roll thin strip continuous casting fine-grain oriented silicon steel thin strip has a fine and uniform solidification structure;

[0038] Molten steel with different components was used for comparison experiments as above, and the components were C0.003% by mass percentage, Si 3.6%, Mn 0.23%, S 0.035%, Als 0.03%, N 0.007%, Ti 0.30%, O<0.004% , P<0.01%, the balance is Fe; the average grain size is 370mm, and the thin strip blank has a coarse and uneven solidification structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com