Deacidification and Fraction Recovery System of High Acid Value Vegetable Oil

A recovery system and vegetable oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of lower vacuum degree at the bottom of the tower, lower deacidification capacity, incomplete deacidification, etc., to achieve enhanced deacidification effect and ensure acidity The effect of value requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

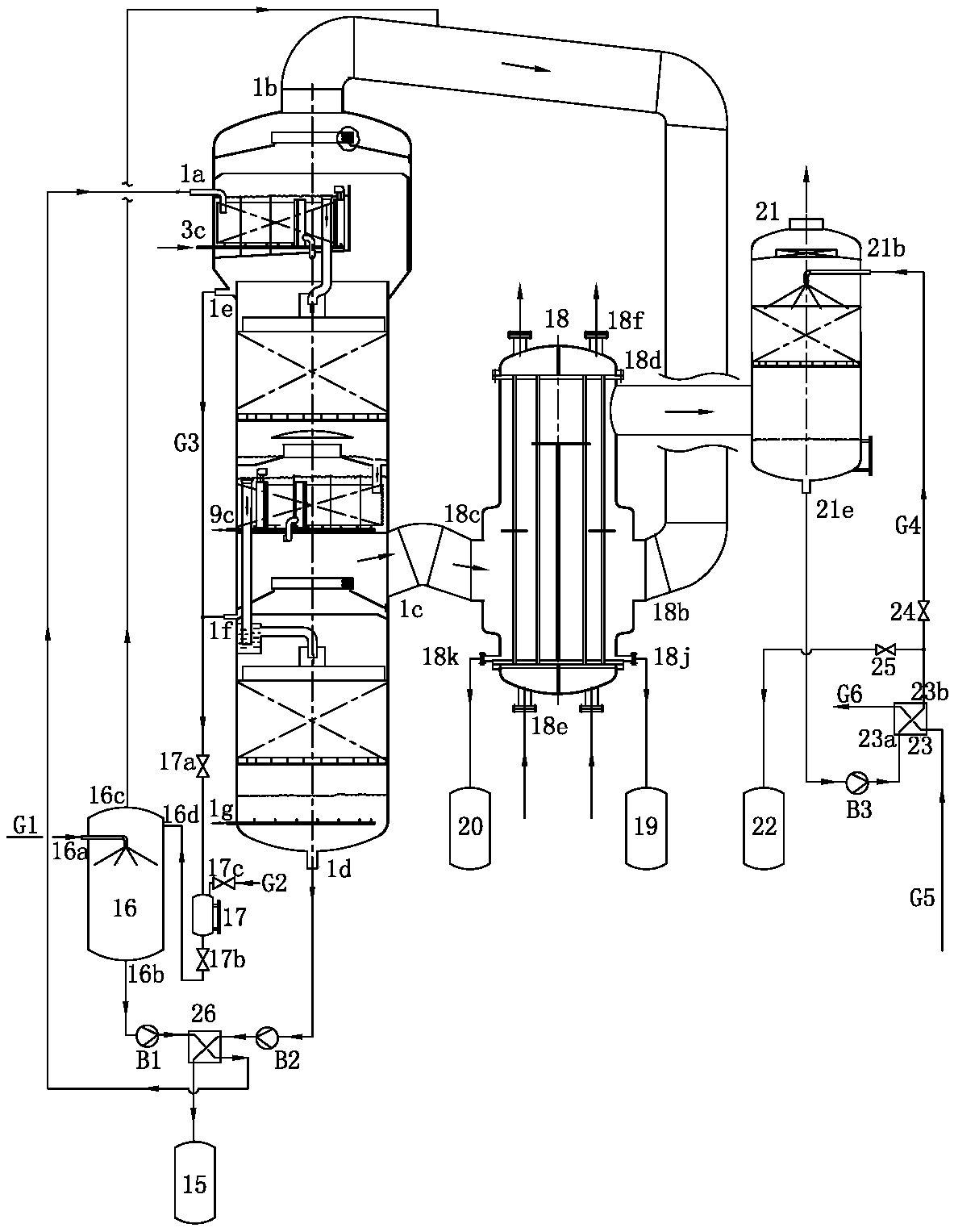

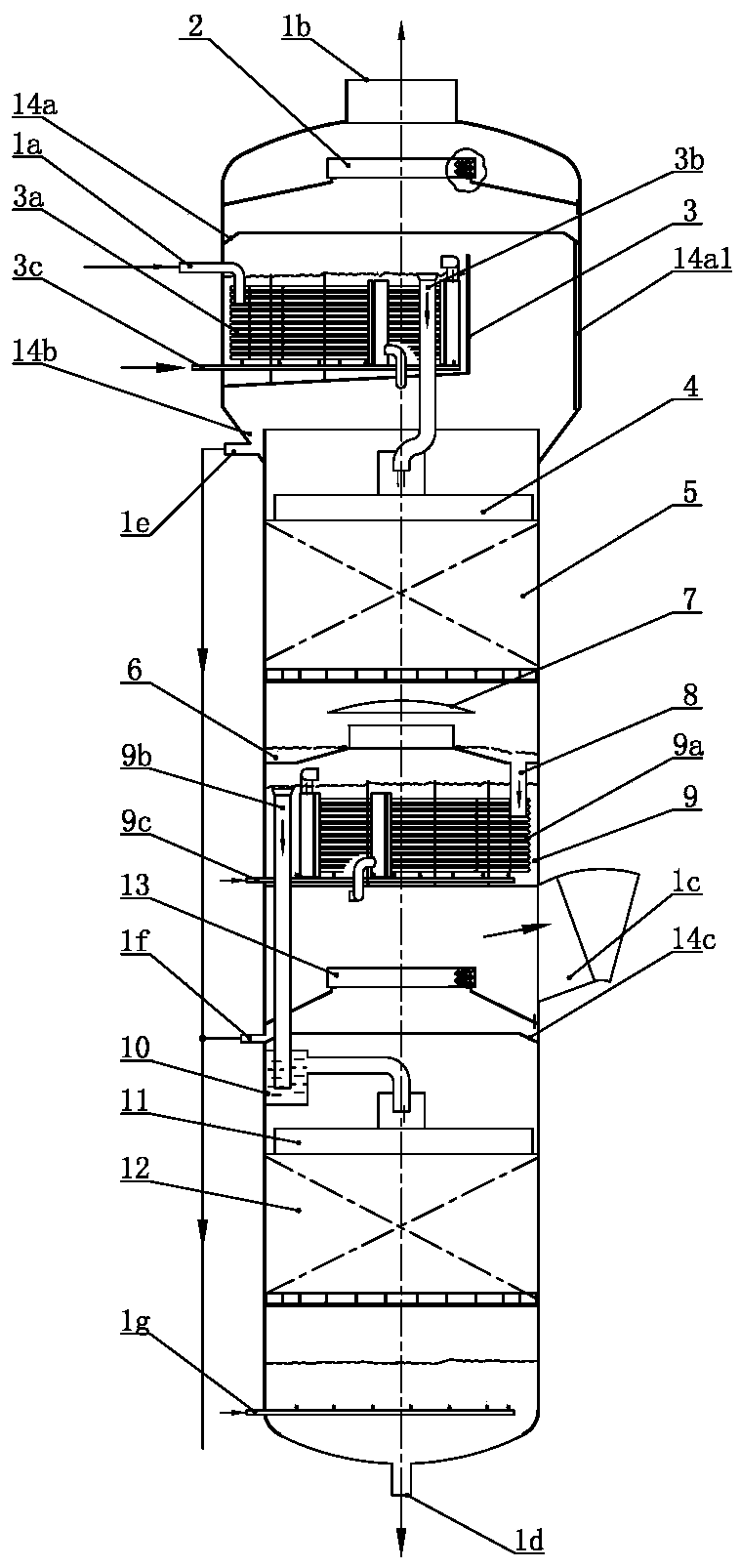

[0037] Such as figure 1 As shown, the deacidification and fraction recovery system of high acid value vegetable oil of the present invention comprises raw material oil pipe G1, secondary distillation tower 1, vacuum raw material tank 16 and condensation recoverer 18, and the inner chamber top of vacuum raw material tank 16 is provided with raw material tank spray The shower pipe 16a, the raw material tank vacuum port 16c at the top of the vacuum raw material tank 16 is connected with the vacuum pumping system, the outlet of the raw material oil pipe G1 is connected with the inlet of the raw material tank spray pipe 16a, and the raw material tank oil outlet 16b at the bottom of the vacuum raw material tank 16 It is connected with the inlet of the crude oil pump B1, the outlet of the crude oil pump B1 is connected with the feed oil inlet of the vegetable oil heat exchanger 26, and the feed oil outlet of the vegetable oil heat exchanger 26 is connected with the inlet of the distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com