Fertilizing machine for agricultural planting

A fertilizer applicator and agricultural technology, applied in the agricultural field, can solve the problems of affecting rice fertilization, clogging of the discharge port, sticking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

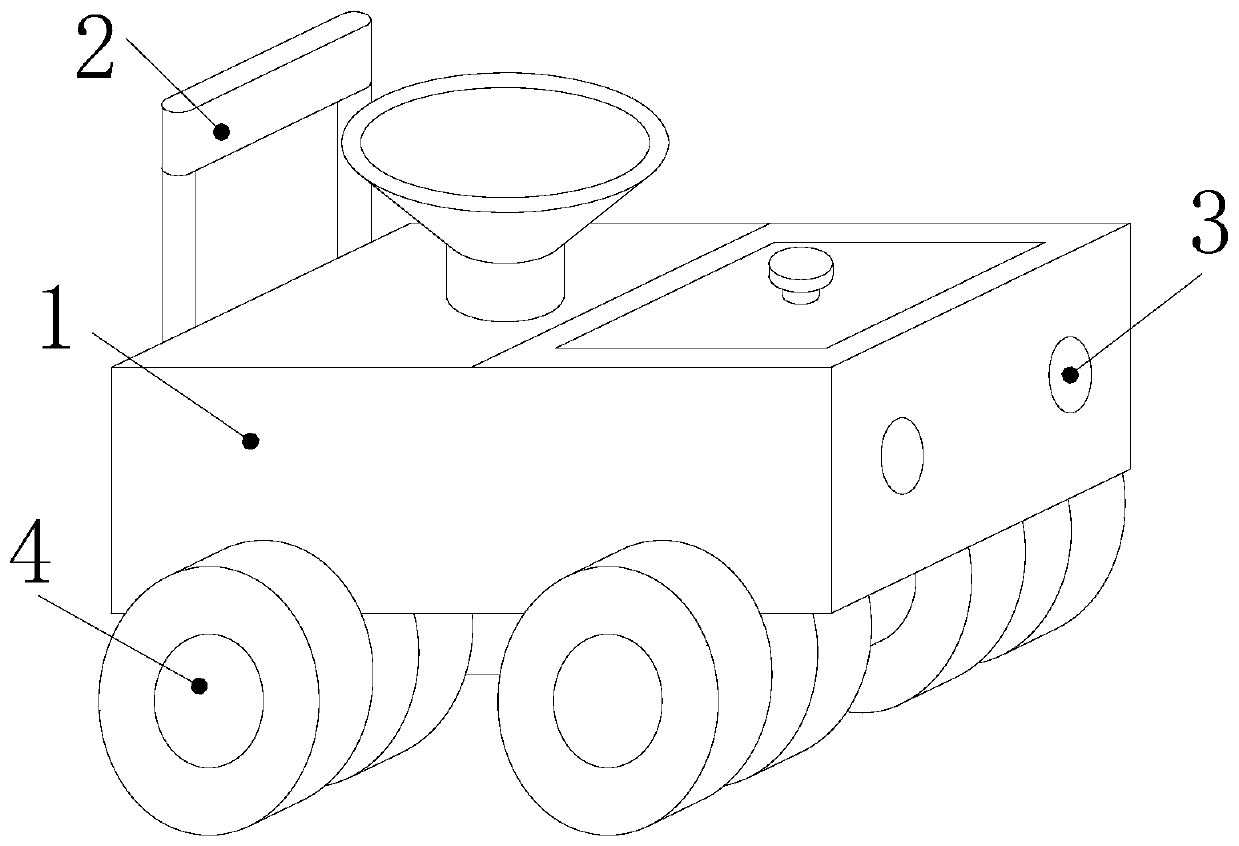

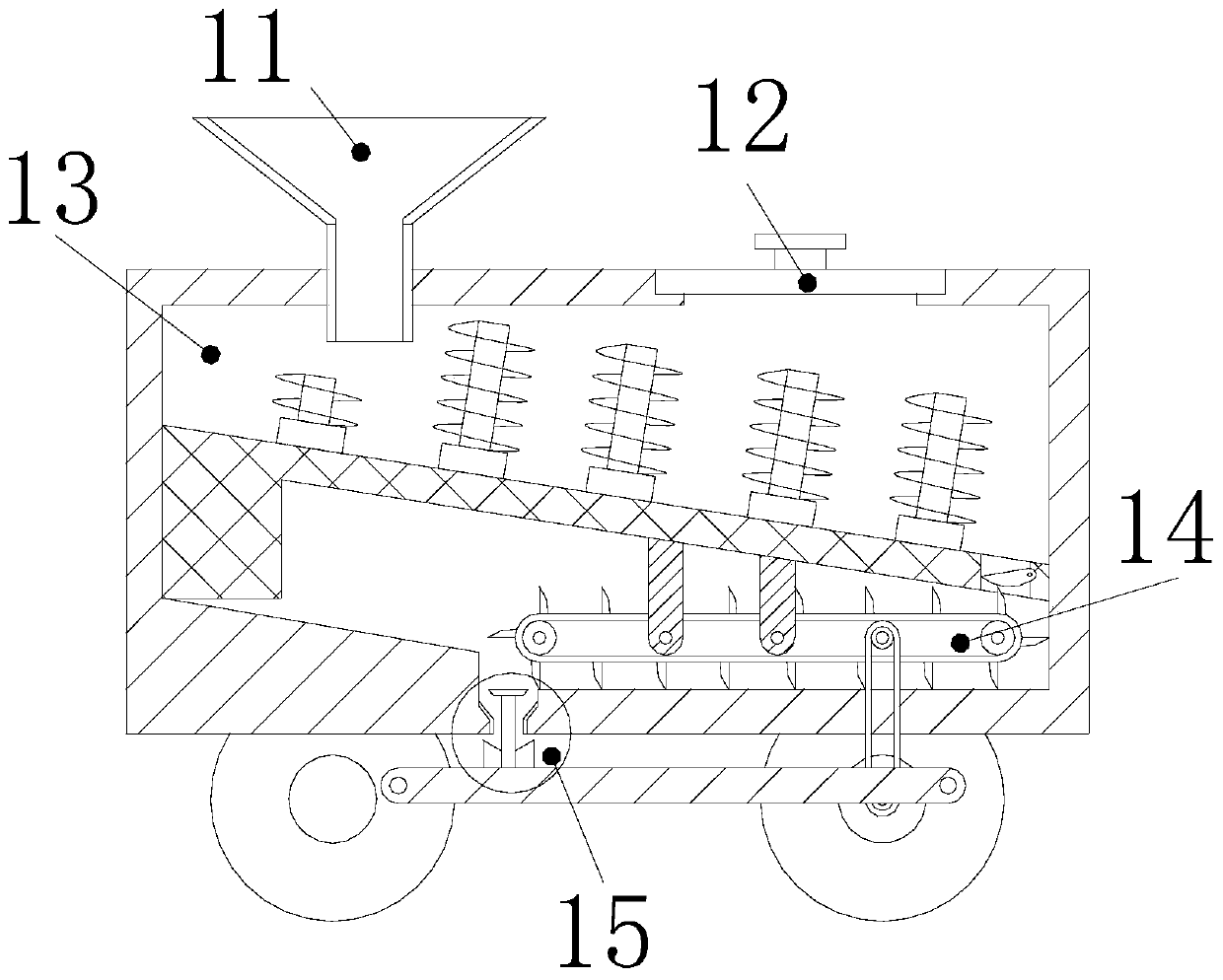

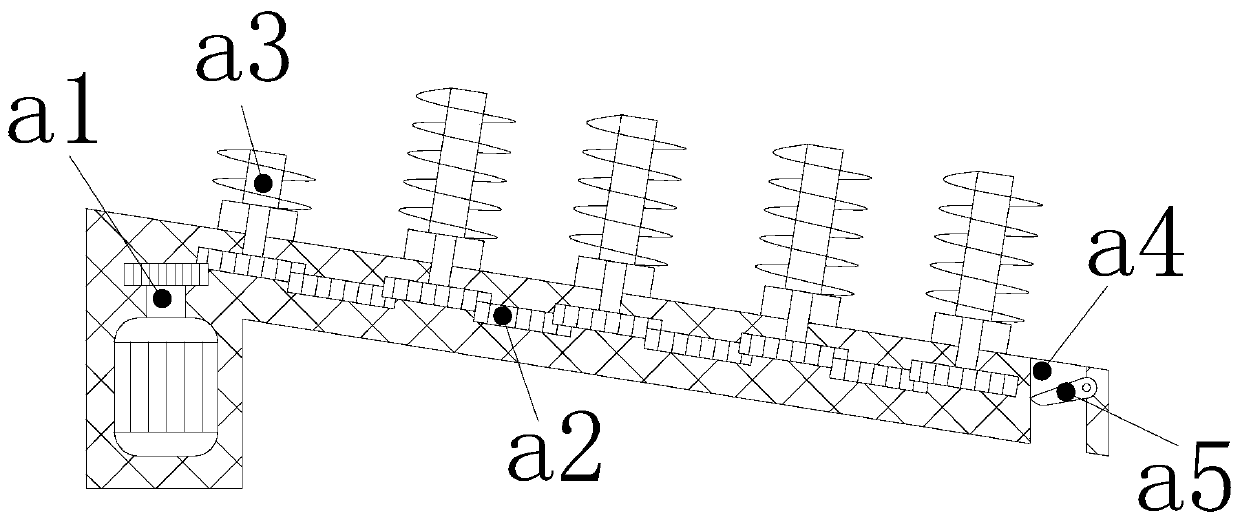

[0026] See Figure 1-Figure 4 :

[0027] A fertilizer applicator for agricultural planting, which structure includes a fertilizer transport box 1, a handle 2, a lighting lamp 3, and a movable wheel 4. The bottom of the fertilizer transport box 1 is equipped with a movable wheel 4, and the handle 2 is connected to the fertilizer transport by welding. On one side of the box 1, the lighting lamp 3 is embedded on the other side of the fertilizer transport box 1. The fertilizer transport box 1 includes a feeding hopper 11, a cleaning cover 12, a mixing chamber 13, a guide belt 14, and a fertilizer tank 15. The feeding hopper 11 and the cleaning cover 12 are respectively embedded on the upper surface of the fertilizer transport box 1, the mixing chamber 13 is embedded in the inner wall of the fertilizer transport box 1, and the guide belt 14 is connected to the inside of the fertilizer transport box 1 through a gap. The fertilization tank 15 penetrates the bottom of the fertilizer tran...

Embodiment 2

[0032] See Figure 5-Figure 7 :

[0033] In the figure, the fertilization trough 15 includes a discharge port b1, a lifting rod b2, and a limit plate b3. The discharge port b1 and the fertilization tank 15 are an integrated structure, and the lifting rod b2 is connected to the discharge port through a gap. Inside b1, the limiting plate b3 is embedded on the top of the lifting rod b2, and the limiting plate b3 is of a truncated cone shape and is arranged above the discharge port b1 to prevent the lifting rod b2 from falling out of the fertilizing tank 15.

[0034] In the figure, the lifting rod b2 includes a solid tube b21, a fertilization hole b22, a fertilization tube b23, and a guide plate b24. The solid tube b21 is embedded in the upper half of the lifting rod b2, and the fertilization hole b22 is embedded in the lifting rod. On surface b2, the fertilization pipe b23 is located below the solid pipe b21, the guide plate b24 is connected to the outside of the fertilization pipe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com