Dewatering equipment for foamed plastic

A technology of foam plastics and equipment, which is applied in the field of foam plastics, and can solve problems such as clogged drainage holes, foam detachment, and affecting water removal from foam plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

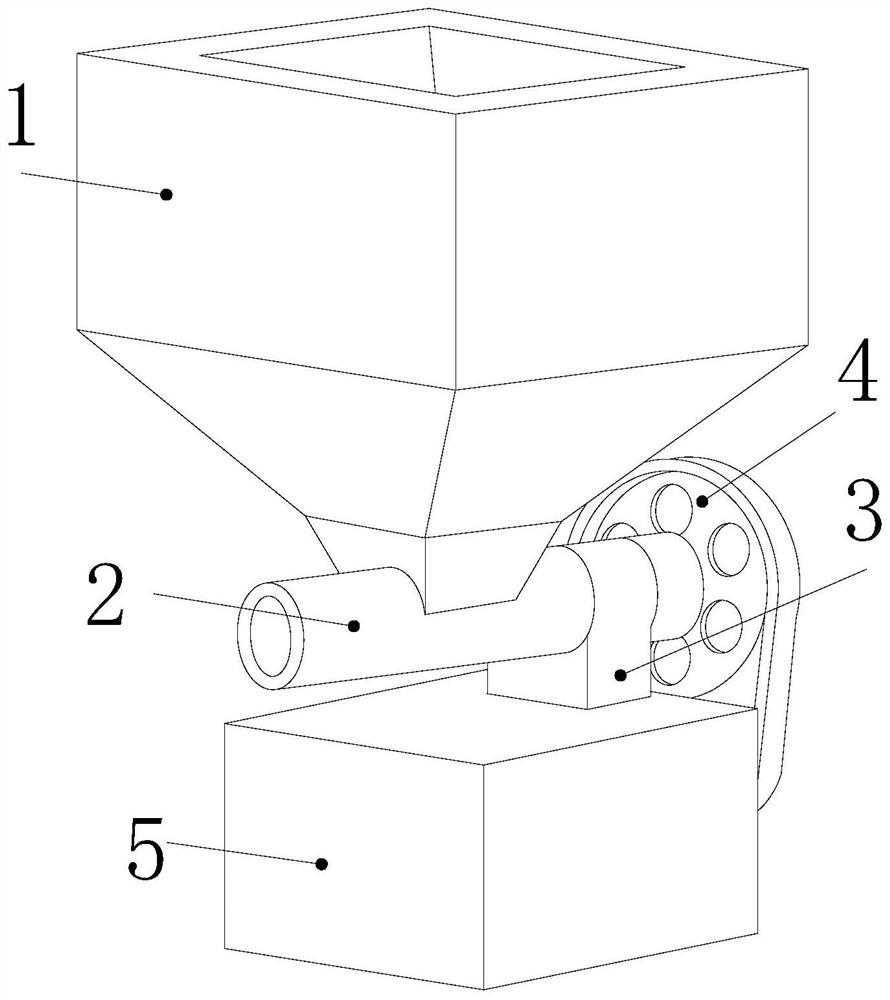

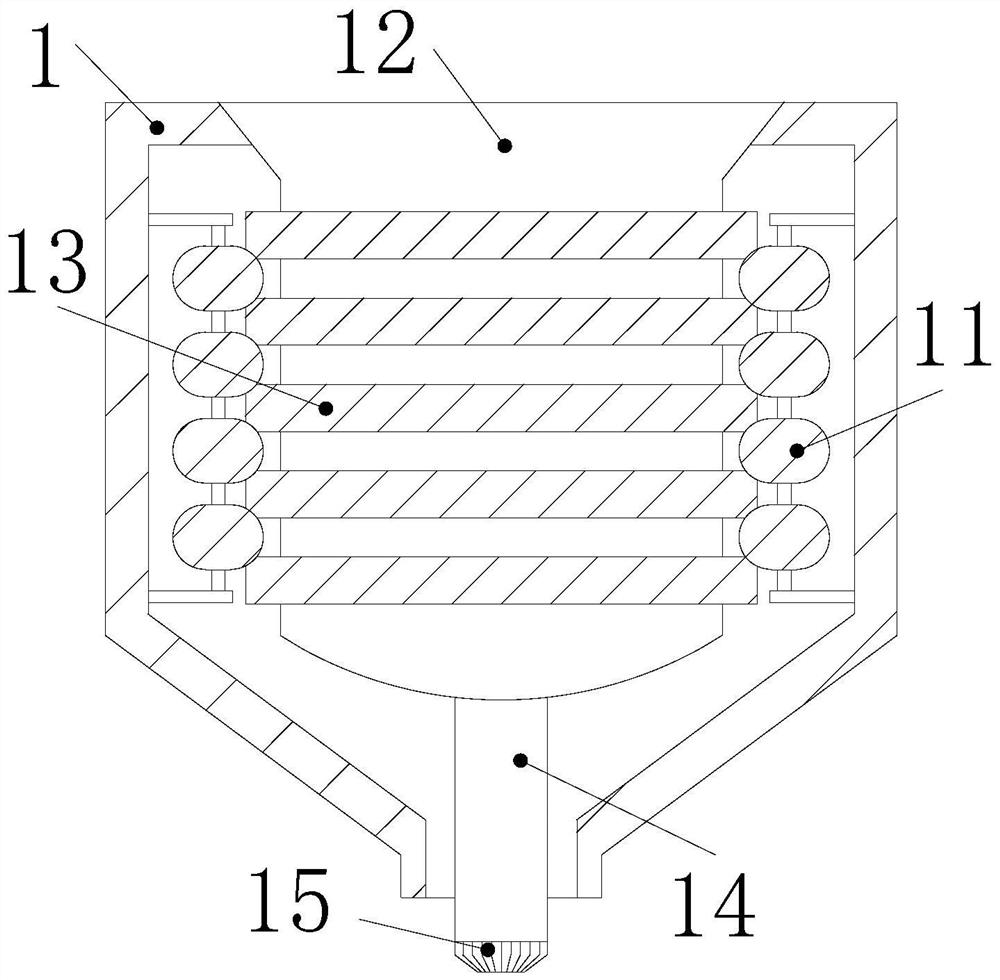

[0029] The invention provides a water removal device for foamed plastics. Its structure includes a feed port 1, a discharge pipe 2, a support platform 3, a rotating block 4, and a machine base 5. The bottom of the feed port 1 is embedded in the discharge pipe. 2, the discharge pipe 2 is welded on the upper surface of the support platform 3, the bottom of the support platform 3 is welded to the top of the machine base 5, the rotary block 4 is mounted on the back of the discharge pipe 2, and the feeding port 1 It includes a positioning block 11, a centrifugal cylinder 12, a clamping plate 13, a rotating rod 14, and teeth 15. The outside of the positioning block 11 is embedded in the inner wall of the feeding port 1, and the centrifugal cylinder 12 is installed inside the feeding port 1. The card The plate 13 is welded on the outer surface of the centrifugal cylinder 12 and engages with the positioning block 11. The top of the rotating rod 14 is welded on the bottom of the centrif...

Embodiment 2

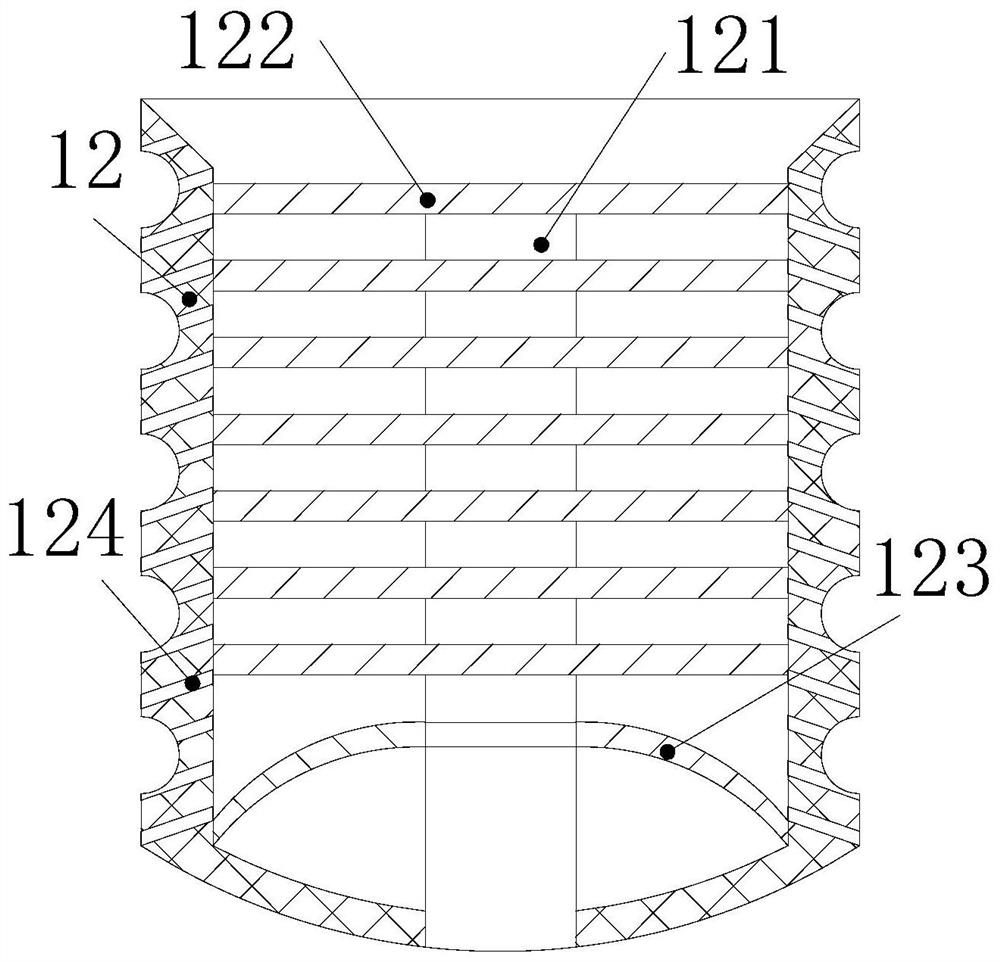

[0036] In the figure, the centrifugal cylinder 12 includes a rotating shaft 121, a rotating plate 122, a sealing plate 123, and a drainage hole 124. The rotating shaft 121 and the centrifugal cylinder 12 are located on the same axis, and the rotating plate 122 is embedded on the outside of the rotating shaft 121 and passed The gap is connected to the inner wall of the centrifugal cylinder 12, the inner side of the sealing plate 123 is close to the outer surface of the rotating shaft 121, and the outer side of the sealing plate 123 is welded on the inner wall of the centrifugal cylinder 12, the drainage hole 124 runs through the inner wall of the centrifugal cylinder 12, and the sealing plate 123 is made of rubber and the inner side is higher than the outer side, and the drainage hole 124 is inclined, and the outer side of the drainage hole 124 is downward, which is beneficial to throwing out the moisture in the foam plastic under the rotation of the centrifugal cylinder 12 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com