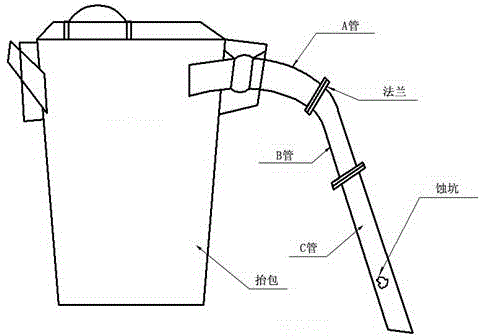

Healant for electric shock pits in aluminum absorbing pipe and repairing method thereof

A technology of electric shock pit and repair agent for aluminum suction tube, applied in the field of electrolytic aluminum, can solve the problems of difficult process operation, scrapped tube wall of C tube, deformation and damage to aluminum water, etc., so as to reduce the cost of electrolytic aluminum production and reduce the single use cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

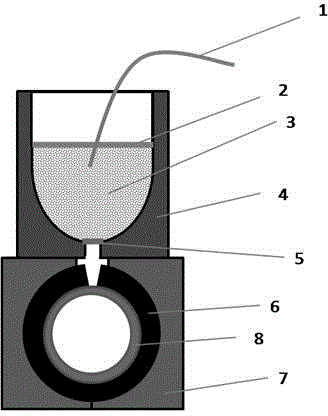

[0031] Clean the inner wall, outer wall and electric shock pit of the aluminum suction pipe C that is scrapped due to electric shock breakdown with tools such as aluminum suction pipe cleaning machine, file and small hammer, and clean the dust at the corrosion pit with compressed air. Brush and dip in alcohol to wet the pit for 2-3 times, and then place the annular graphite baffle on the inner wall of the pit of the aluminum suction tube to seal the pit. Afterwards, assemble the special fixed mould, the aluminum suction tube and the charging mold. There is a small hole at the bottom of the charging mold that communicates with the corrosion pit of the aluminum suction tube, and put the baffle into the bottom of the charging mold. Weighing mass ratio is iron oxide 49.5%, dichromium oxide 11.4%, calcium sulfate 1.94%, calcium fluoride 2.05%, iron 11.25%, silicon 2%, manganese 0.5%, molybdenum 0.25%, scandium 0.1%, aluminum powder 21.01% 200 mesh repair agent, mix well and set asi...

Embodiment 2

[0033]Clean the inner wall, outer wall and electric shock pit of the aluminum suction pipe C that is scrapped due to electric shock breakdown with tools such as aluminum suction pipe cleaning machine, file and small hammer, and clean the dust at the corrosion pit with compressed air. Brush and dip in alcohol to wet the pit for 2-3 times, then place the arc-shaped graphite baffle on the inner wall of the pit of the aluminum suction tube and fix it with a clamp to seal the pit. Afterwards, assemble the special fixed mould, the aluminum suction tube and the charging mold. There is a small hole at the bottom of the charging mold that communicates with the corrosion pit of the aluminum suction tube, and put the baffle into the bottom of the charging mold. Weighing mass ratio is iron oxide 51.77%, dichromium oxide 10.16%, calcium sulfate 4.06%, calcium fluoride 2.04%, iron 8.02%, silicon 1.16%, manganese 0.25%, molybdenum 0.26%, scandium 0.05%, aluminum powder 22.23% 300 mesh repair...

Embodiment 3

[0035] Clean the inner wall, outer wall and electric shock pit of the aluminum suction pipe C that is scrapped due to electric shock breakdown with tools such as aluminum suction pipe cleaning machine, file and small hammer, and clean the dust at the corrosion pit with compressed air. Brush and dip in alcohol to moisten the pit for 2-3 times, then place the annular graphite baffle on the inner wall of the pit of the aluminum suction tube to seal the pit. Afterwards, assemble the special fixed mould, the aluminum suction tube and the charging mold. There is a small hole at the bottom of the charging mold that communicates with the corrosion pit of the aluminum suction tube, and put the baffle into the bottom of the charging mold. Weighing mass ratio is iron oxide 40.38%, dichromium oxide 19.89%, calcium sulfate 2.94%, calcium fluoride 2.51%, iron 11.37%, silicon 1.19%, manganese 0.31%, molybdenum 0.26%, scandium 0.06%, aluminum powder 21.09% 300 mesh repair agent, mix well and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com