Device and process for comprehensively treating BOG generated by LNG receiving station at initial stage of production

A technology of comprehensive processing and receiving station, applied in the field of BOG processing of LNG receiving station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

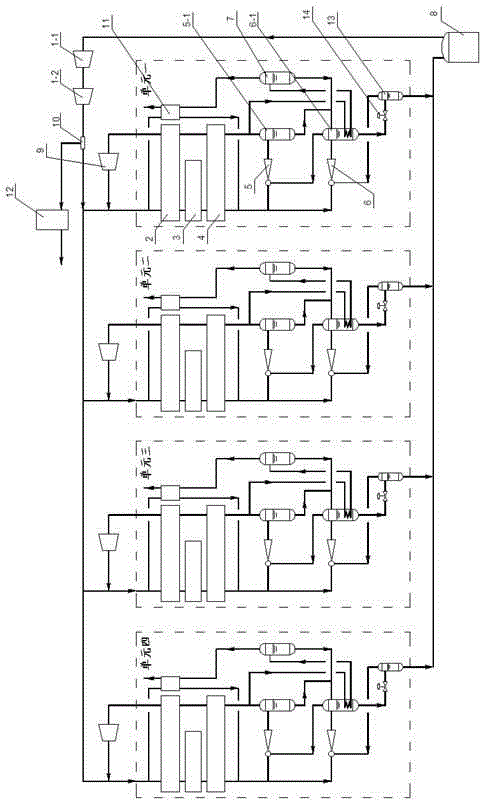

Embodiment 1

[0023] Use a liquefaction cell:

[0024] The comprehensive treatment device includes an LNG storage tank 8, a low-pressure BOG compressor 1-1, a high-pressure BOG compressor 1-2 and a CNG filling interface 10, the BOG gas phase outlet pipeline of the LNG storage tank 8 and the low-pressure BOG compressor 1-1. The inlet is connected, the outlet pipeline of the low-pressure BOG compressor 1-1 is connected with the inlet of the high-pressure BOG compressor 1-2, the outlet pipeline of the high-pressure BOG compressor 1-2 is connected with the inlet of the CNG filling interface 10, and the CNG filling interface 10 is connected The outlet pipeline is divided into two paths, one pipeline is connected to the CNG filling machine 12, and the other pipeline is connected to the inlet of the liquefaction unit, the gas phase outlet pipeline of the liquefaction unit is connected to the circulating BOG compressor 9, and the outlet pipeline of the circulating BOG compressor 9 is connected to th...

Embodiment 2

[0033] Use two liquefaction units set up in parallel:

[0034] The comprehensive treatment device includes an LNG storage tank 8, a low-pressure BOG compressor 1-1, a high-pressure BOG compressor 1-2 and a CNG filling interface 10, the BOG gas phase outlet pipeline of the LNG storage tank 8 and the low-pressure BOG compressor 1-1. The inlet is connected, the outlet pipeline of the low-pressure BOG compressor 1-1 is connected with the inlet of the high-pressure BOG compressor 1-2, the outlet pipeline of the high-pressure BOG compressor 1-2 is connected with the inlet of the CNG filling interface 10, and the CNG filling interface 10 is connected The outlet pipeline is divided into two paths, one pipeline is connected to the CNG filling machine 12, and the other pipeline is connected to the inlet of the liquefaction unit, the gas phase outlet pipeline of the liquefaction unit is connected to the circulating BOG compressor 9, and the outlet pipeline of the circulating BOG compresso...

Embodiment 3

[0043] Using four liquefaction units set up in parallel:

[0044] The comprehensive treatment device includes an LNG storage tank 8, a low-pressure BOG compressor 1-1, a high-pressure BOG compressor 1-2 and a CNG filling interface 10, the BOG gas phase outlet pipeline of the LNG storage tank 8 and the low-pressure BOG compressor 1-1. The inlet is connected, the outlet pipeline of the low-pressure BOG compressor 1-1 is connected with the inlet of the high-pressure BOG compressor 1-2, the outlet pipeline of the high-pressure BOG compressor 1-2 is connected with the inlet of the CNG filling interface 10, and the CNG filling interface 10 is connected The outlet pipeline is divided into two paths, one pipeline is connected to the CNG filling machine 12, and the other pipeline is connected to the inlet of the liquefaction unit, the gas phase outlet pipeline of the liquefaction unit is connected to the circulating BOG compressor 9, and the outlet pipeline of the circulating BOG compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com