A method for preparing formate, acetate and levulinate by utilizing straw biomass

A technology of levulinic acid ester and biomass, which is applied in the field of formate, acetate, and levulinic acid ester preparation. It can solve the problems of accumulation, large by-products, and difficulty in removing levulinic acid, so as to improve the utilization rate , Lighten the detoxification process route and overcome the effect of massive accumulation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

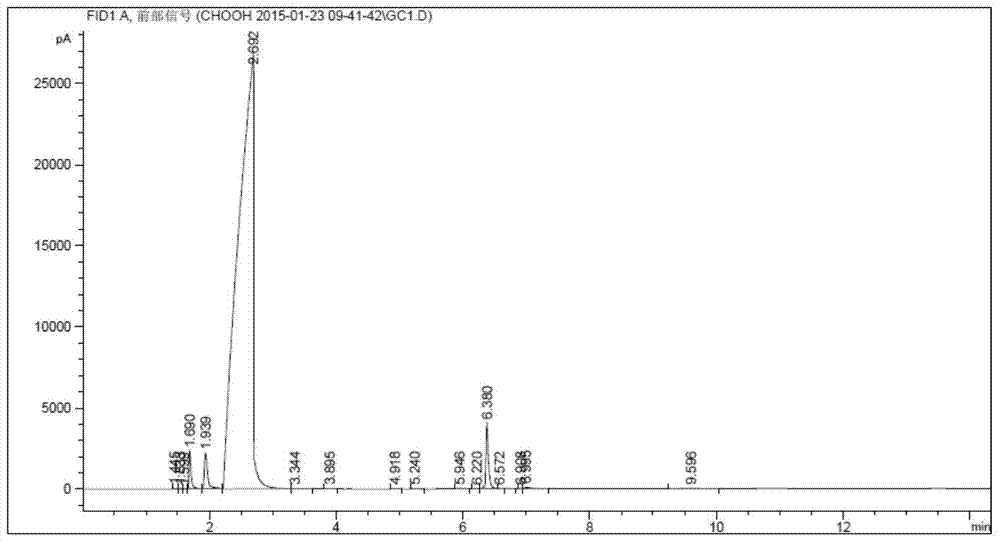

[0016] (1) In a 5L electric heating reactor with a stirring device, add 300g of wheat straw (the mass fraction of cellulose is 40.21%) and 3000mL of ethanol sulfuric acid solution (the liquid-solid ratio of straw to alkyd aqueous solution is 10mL / g ), the ethanol concentration is 25wt%, the sulfuric acid concentration is 3.0wt%, the stirring rate is 60r / min, the reaction temperature is 80-200°C, and the reaction time is 180min. After reaction finishes, be cooled to room temperature, carry out distillation, the distillate that obtains is the mixture of ethyl formate, ethyl acetate and ethanol (the GC collection of illustrative plates of distillate is as figure 1 shown), the mixture at the bottom of the still is still liquid and hydrolysis slag;

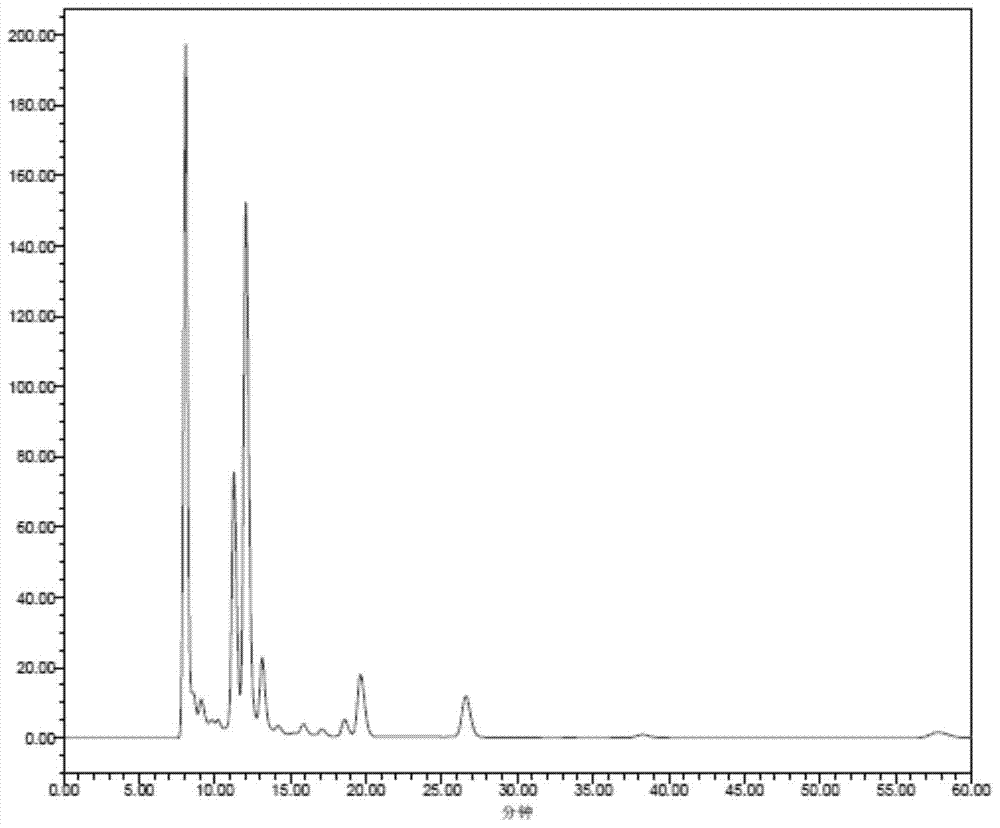

[0017] (2) The bottom mixture was subjected to vacuum filtration for solid-liquid separation to obtain filtrate and 185 g of filter residue respectively. The resulting filtrate is a hydrolyzate mainly containing glucose, xylose, arabi...

Embodiment 2

[0019] (1) In a 5L electric heating reactor with a stirring device, add 500g of wheat straw (the mass fraction of cellulose is 40.21%) and 3000ml of methanolic hydrochloric acid solution (the liquid-solid ratio of straw to alkyd aqueous solution is 6mL / g ), the concentration of methanol is 30wt%, the concentration of hydrochloric acid is 3.5wt%, the stirring speed is 80r / min, the reaction temperature is 80~200°C, and the reaction time is 90min. After the reaction is finished, cool to room temperature and carry out distillation. The distillate obtained is a mixture of methyl formate, methyl acetate and methanol, and the mixture at the bottom of the still is still liquid and hydrolysis residue;

[0020] (2) The mixture at the bottom of the still was subjected to vacuum filtration for solid-liquid separation to obtain filtrate and 460 g of filter residue respectively. The resulting filtrate is a hydrolyzate mainly containing glucose, xylose, arabinose and methyl levulinate.

[0...

Embodiment 3

[0023] (1) In a 5L electric heating reactor with a stirring device, add 600g corn stalks (the mass fraction of cellulose is 32.22%) and 3000ml ethanol phosphoric acid solution (the liquid-solid ratio of straw to alkyd aqueous solution is 5mL / g ), the ethanol concentration is 1.0wt%, the phosphoric acid concentration is 1.5wt%, the stirring rate is 80r / min, the reaction temperature is 80-200°C, and the reaction time is 120min. After the reaction is finished, cool to room temperature and distill, the distillate obtained is a mixture of ethyl formate, ethyl acetate and ethanol, and the mixture at the bottom of the still is still liquid and hydrolysis residue;

[0024] (2) The bottom mixture was subjected to vacuum filtration for solid-liquid separation to obtain filtrate and 536 g of filter residue respectively. The resulting filtrate is a hydrolyzate mainly containing glucose, xylose, arabinose and ethyl levulinate.

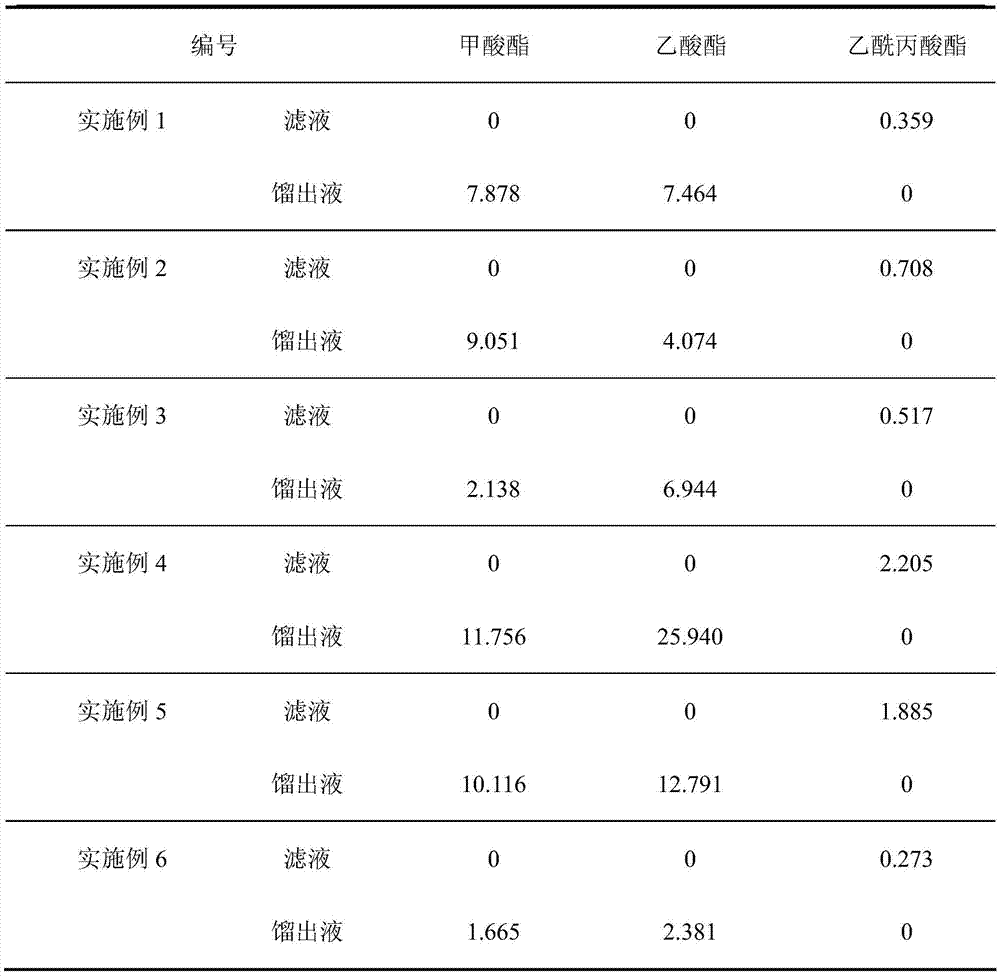

[0025] Referring to Table 1, it is known that the main subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com