A method for preparing porous cerium-based oxides from a water-soluble cerium precursor

A water-soluble, composite oxide technology, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., can solve problems such as product collapse and complex preparation of cerium precursors, and achieve simple preparation, superior catalytic performance, and improved ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

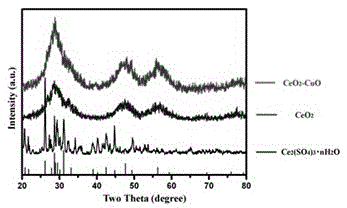

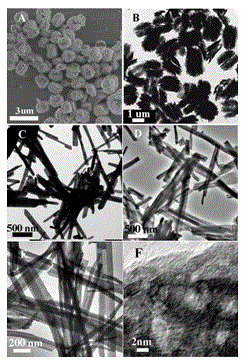

[0029] Preparation method of flower-like water-soluble cerium precursor and cerium-based oxide

[0030] 148mgCeCl 3 ·7H 2 O was dissolved in 15.75ml absolute ethanol, and 0.25ml H was added at room temperature 2 SO 4 (5M) solution, stirred and reacted for 10 minutes, transferred to the reaction kettle, and kept at 160° C. for 3 hours; cooled, washed with ethanol several times, and dried to obtain a flower-shaped water-soluble cerium precursor;

[0031] Take 150 mg of the above cerium precursor and add 30 ml of saturated NaOH ethanol solution, let it stand at room temperature for 2 days, wash and dry, and then the flower-like cerium-based oxide can be obtained.

Embodiment 2

[0033] Preparation method of rod-shaped water-soluble cerium precursor and cerium-based oxide

[0034] 148mgCeCl 3 ·7H 2 O was dissolved in 14.67ml absolute ethanol, and 1.33ml H was added at room temperature 2 SO 4 (0.75M) solution, stirred and reacted for 10 minutes, transferred to the reaction kettle, and kept at 160°C for 3 hours; cooled, washed with ethanol several times, and dried to obtain a rod-shaped water-soluble cerium precursor;

[0035] Take 150 mg of the above-mentioned cerium precursor and add 30 ml of saturated NaOH ethanol solution, let it stand at room temperature for 2 days, wash and dry, and the rod-shaped cerium-based oxide can be obtained.

Embodiment 3

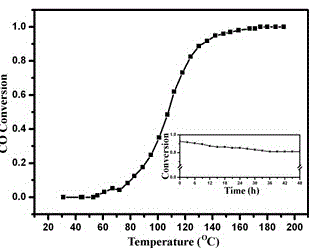

[0037] Preparation method of porous cerium-copper composite oxide

[0038] Weigh 0.5mmolCu(ac) 2 ·H 2 Dissolve O in absolute ethanol; disperse 150 mg of cerium-based oxide in ethanol solution, stir for 10 minutes, transfer to a reaction kettle, and keep at 120°C for 6 hours; cool, wash and dry to obtain porous cerium-copper composite oxides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com