3D integrated framework of ultrahigh frequency power converter

A power converter, ultra-high frequency technology, applied in the direction of transformer/inductor coil/winding/connection, inductor, fixed inductor, etc., can solve the problem of large switching loss and voltage, current stress, and resonance of resonant components in the interference circuit , Increase device voltage stress and other issues, achieve the effect of improving the working environment, ensuring miniaturization, and reducing parasitic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0044] Figure 5 An exploded perspective schematic diagram of the 3D integrated architecture of the UHF power converter according to the first embodiment of the present invention is given, Image 6 Front view of the 3D integrated architecture of the UHF power converter.

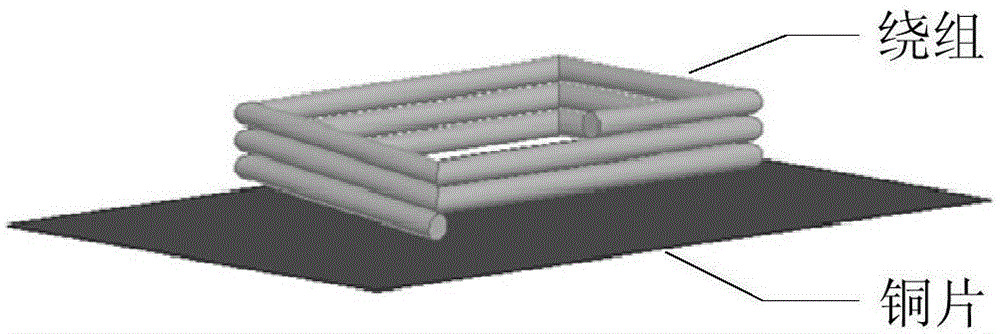

[0045] like Figure 5 and Image 6 As shown, a 3D integrated structure of an ultra-high frequency power converter includes a PCB circuit board 1, a first soft magnetic film layer 2a, a first insulating layer 3a, a second insulating layer 3b, a heat sink 4, an inductance winding 5a, Transformer winding 5b, wire 6. A first soft magnetic thin film layer 2a is provided between the winding layers 5a, 5b and the PCB circuit board 1 to achieve magnetic field shielding between the windings and the PCB circuit board 1 . A first insulating layer 3a is arranged between the winding layers 5a, 5b and the first soft magnetic film layer 2a, and a second insulating layer 3b is arranged between the first soft magnetic film ...

no. 2 example

[0053] Figure 7 The 3D integrated architecture of the UHF power converter of the second embodiment of the present invention is given. The difference from the first embodiment is that the winding unit (including the winding layer and the corresponding soft magnetic film) in the second embodiment layers and insulating layers) are placed on only one side of the PCB board, for example, only the winding unit is placed on top of the PCB board.

no. 3 example

[0055] Figure 8 The 3D integrated structure of the UHF power converter according to the third embodiment of the present invention is given, including a PCB circuit board 1, a first soft magnetic film layer 2a, a second soft magnetic film layer 2b, a first insulating layer 3a, a first The second insulating layer 3b, the third insulating layer 3c, the heat sink 4, the inductor winding 5a, the transformer winding 5b, and the wire 6. The difference from the first embodiment is that in the third embodiment, a second soft magnetic thin film layer 2b is provided between the winding layers 5a, 5b and the external metal (such as a casing, etc.) to ensure that the magnetic field of the winding is not affected by the magnetic field. Interference from external metals. In addition, a third insulating layer 3c is provided between the second soft magnetic thin film layer 2b and the winding layers 5a and 5b to ensure electrical isolation.

[0056] The soft magnetic film layer 2b uses soft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com