Blue light phosphor powder for white light LED and preparation method thereof, and white light LED light emitting device

A technology for light-emitting devices and phosphors, which is applied in the fields of light-emitting materials, chemical instruments and methods, electrical components, etc., can solve the problems of poor sulfide stability and anti-ultraviolet radiation resistance, high cost, and short service life of white LEDs. , to achieve good chemical stability and temperature quenching characteristics, huge social and economic benefits, wide excitation and emission range effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

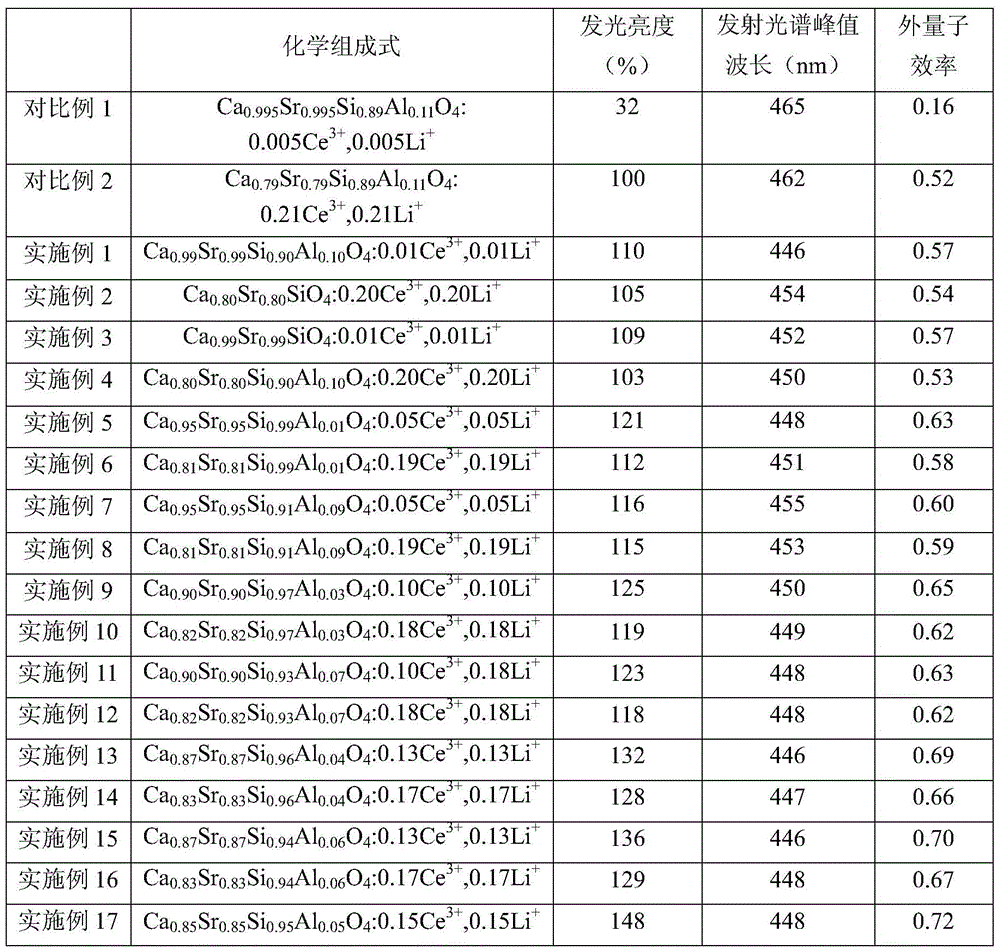

Examples

Embodiment 1

[0034] The chemical composition formula of the blue light phosphor powder for white light LED of this embodiment is Ca 1-x Sr 1-x Si 1-y al y o 4 :xCe 3+ ,xLi + , where x=0.01, y=0.10, the specific expression is Ca 0.99 Sr 0.99 Si 0.90 al 0.10 o 4 :0.01Ce 3+ ,0.01Li + .

[0035] Press Ca 0.99 Sr 0.99 Si 0.90 al 0.10 o 4 :0.01Ce 3+ ,0.01Li + The metering ratio of each element, accurately weigh 0.330gCaCO 3 ,0.487g SrCO 3 ,0.001g Li 2 CO 3 ,0.180g SiO 2 ,0.017g Al 2 o 3 ,0.006g CeO 2 , High-purity powder raw materials, put them in an agate mortar and grind for about 30 minutes, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to the alumina crucible, add and nest the small corundum crucible in the large crucible with carbon powder, cover it and place it in a high-temperature reaction furnace for sintering at 1400°C for 4 hours, take it out after natural cooling, and grind again In about 30 minutes, a single-phase Ca...

Embodiment 2

[0037] The chemical composition formula of the blue light phosphor powder for white light LED of this embodiment is Ca 1-x Sr 1-x Si 1-y al y o 4 :xCe 3+ ,xLi + , where x=0.20, y=0, the specific expression is Ca 0.80 Sr 0.80 SiO 4 :0.20Ce 3+ ,0.20Li + .

[0038] Press Ca 0.80 Sr 0.80 SiO 4 :0.20Ce 3+ ,0.20Li + The metering ratio of each element, accurately weigh 0.267g CaCO 3 ,0.394g SrCO 3 ,0.025g Li 2 CO 3 ,0.200g SiO 2 ,0.115g CeO 2 , High-purity powder raw materials, put them in an agate mortar and grind for about 30 minutes, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to the alumina crucible, add and nest the small corundum crucible in the large crucible with carbon powder, cover it and place it in a high-temperature reaction furnace for sintering at 1300°C for 12 hours, take it out after natural cooling, and grind again About 15 minutes to get single-phase Ca 0.80 Sr 0.80 SiO 4 :0.20Ce 3+ ,0.20Li + Phosp...

Embodiment 3

[0040] The chemical composition formula of the blue light phosphor powder for white light LED of this embodiment is Ca 1-x Sr 1-x Si 1-y al y o 4 :xCe 3+ ,xLi + , where x=0.01, y=0, the specific expression is Ca 0.99 Sr 0.99 SiO 4 :0.01Ce 3+ ,0.01Li + .

[0041] Press Ca 0.99 Sr 0.99 SiO 4 :0.01Ce 3+ ,0.01Li + The metering ratio of each element, accurately weigh 0.330g CaCO 3 ,0.487g SrCO 3 ,0.001g Li 2 CO 3 ,0.200g SiO 2 ,0.006g CeO 2 , High-purity powder raw materials, put them in an agate mortar and grind for about 30 minutes, so that the raw materials are fully mixed and even. Transfer the mixed raw materials to the alumina crucible, add and nest the small corundum crucible in the large crucible with carbon powder, cover it and place it in a high-temperature reaction furnace for sintering at 1400°C for 6 hours, take it out after natural cooling, and grind again In about 20 minutes, a single-phase Ca 0.99 Sr 0.99 SiO 4 :0.01Ce 3+ ,0.01Li + Phospho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com