Method and device for continuously concentrating glyoxylic acid

A technology of glyoxylic acid and concentrated liquid, applied in the field of concentration, can solve the problems affecting the quality and stability of glyoxylic acid products, low equipment capacity, and high energy consumption, so as to achieve good product quality and quality stability, and increase equipment capacity. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

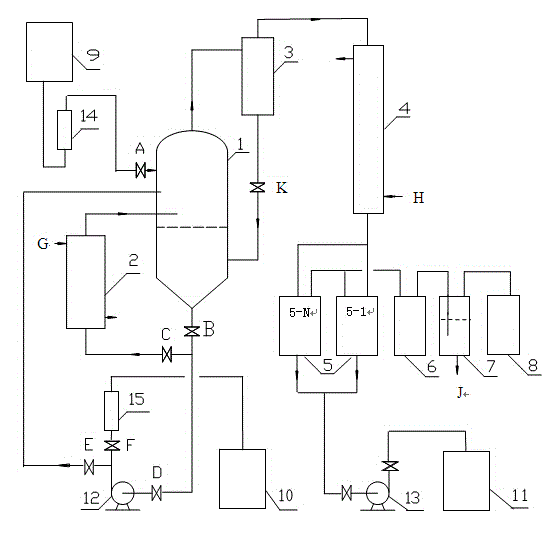

[0040] see image 3 , Embodiment 1 provides a kind of device of continuously concentrating glyoxylic acid, and this device comprises evaporator 1, heater 2, demister 3, condenser 4, receiving tank 5, buffer tank 6, scrubbing tank 7, high Vacuum unit 8, raw liquid container 9, concentrated liquid container 10, distillate liquid container 11, production pump 12, distillate liquid delivery pump 13, raw liquid feed flow meter 14, concentrated liquid production flow meter 15, etc. Wherein, the aforementioned structures or their inner linings are all made of materials capable of resisting material corrosion.

[0041] Among them, the evaporator 1 and the heater 2 are connected through a circulation pipeline to form a circulation loop. The evaporator 1 has its own concentrated liquid circulation to form a self-circulation to improve heat transfer efficiency. The evaporator 1, demister 3, condenser 4, receiving Tank 5, buffer tank 6, scrubber tank 7 and high-vacuum unit 8 are connecte...

Embodiment 2

[0048] see figure 2 , the embodiment of the present invention provides a method for continuously concentrating glyoxylic acid, using the device of embodiment 1, the specific operation process of the method is as follows:

[0049] (1) Start-up system vacuum debugging process: After checking that all equipment is normal, start the high-vacuum unit 8, debug the system vacuum, and stabilize the no-load vacuum degree displayed by the evaporator 1 pressure gauge at 0.95kgf / cm 2 above.

[0050] (2) Pre-feeding concentration and stabilization process: Open the discharge valve of the stock solution container 9 and the feed valve A of the evaporator 1, and use the vacuum to add the stock solution of the glyoxylic acid aqueous solution for the first time to 70-85% of the normal maximum capacity of the evaporator 1 Finally, close the feed valve A and stop feeding. Open the discharge valve B of the evaporator, the feed valve C of the heater, the heating medium G of the heater 2, the coo...

Embodiment 3

[0057] Embodiment 3 provides a kind of method of continuously concentrating glyoxylic acid, comprises the following steps:

[0058] In step (1), the no-load vacuum is stabilized at 0.97-0.98kgf / cm 2 .

[0059] In step (2), the amount of the glyoxylic acid solution stock solution added for the first time is 70% of the normal maximum capacity of the evaporator 1, and as the concentration proceeds, additional stock solution is added to maintain the liquid level of the evaporator 1 at the normal maximum capacity 70% of. The concentration temperature is 50-56°C.

[0060] In step (3), the liquid level in the evaporator 1 is stabilized at 80% of the normal maximum capacity by adjusting the feed flow rate and the output flow rate. The mass concentration of glyoxylic acid in the concentrated solution is specified as 52-54%.

[0061] In step (4), evaporator 1 vacuum degree 0.92-0.93kgf / cm 2 , the concentration temperature is 50-56°C, and the liquid level in the evaporator 1 is stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com