Pavement/bridge deck concrete fast mending material and application thereof

A technology for repairing materials and concrete, applied in the field of building materials, can solve the problems of short service life, difficult repairing of repairing materials, long curing time, etc., and achieve the effects of high early strength, improved flexibility, and reduced water addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of pavement / bridge deck concrete rapid repair material, by weight, comprises 20 parts of sulphoaluminate cement, 9 parts of 52.5 ordinary Portland cement, 7 parts of ethylene and vinyl acetate polymer rubber powder, 0.5 part of aluminum sulfate, 1 part of water glass, 0.1 part of organic silicon, 1 part of gypsum, 3 parts of slag, 0.1 part of silicon micropowder, 0.5 part of HPCA high-performance concrete expansion agent, 3 parts of fly ash, 20 parts of washed and dried sand, 25 parts of corundum, steel 1.5 parts of fiber, 1.5 parts of PP fiber, 2 parts of polycarboxylate superplasticizer, 0.3 part of boric acid, 0.1 part of sodium gluconate and 0.2 part of lithium carbonate.

[0029] The aspect ratio of the steel fiber is 45-65, and the section diameter is 0.40-0.65mm.

[0030] Mix all kinds of raw materials evenly to get the repair material.

Embodiment 2

[0032] A kind of pavement / bridge deck concrete rapid repair material, by weight, comprises 25 parts of sulfoaluminate cement, 10 parts of 52.5 ordinary portland cement, 10 parts of ethylene and vinyl acetate polymer rubber powder, 1 part of aluminum sulfate, 1.5 parts of water glass, 0.6 parts of organic silicon, 1.5 parts of gypsum, 2.5 parts of slag, 0.3 parts of silicon powder, 1 part of HPCA high-performance concrete expansion agent, 4 parts of fly ash, 25 parts of washed and dried sand, 28 parts of emery, steel 1 part of fiber, 3 parts of PP fiber, 1 part of polycarboxylate superplasticizer, 0.6 part of boric acid, 0.2 part of sodium gluconate and 0.8 part of lithium carbonate.

[0033] The aspect ratio of the steel fiber is 45-65, and the section diameter is 0.40-0.65mm.

[0034] Mix all kinds of raw materials evenly to get the repair material.

Embodiment 3

[0036] A kind of pavement / bridge deck concrete rapid repair material, by weight, comprises 30 parts of sulphoaluminate cement, 8 parts of 52.5 ordinary Portland cement, 5 parts of ethylene and vinyl acetate polymer rubber powder, 1.5 parts of aluminum sulfate, 2 parts of water glass, 1 part of organic silicon, 2 parts of gypsum, 2 parts of slag, 0.5 parts of silicon powder, 0.8 parts of HPCA high-performance concrete expansion agent, 5 parts of fly ash, 30 parts of washed and dried sand, 30 parts of emery, steel 2 parts of fiber, 3 parts of PP fiber, 3 parts of polycarboxylate superplasticizer, 0.8 part of boric acid, 0.3 part of sodium gluconate and 1 part of lithium carbonate.

[0037] The aspect ratio of the steel fiber is 45-65, and the section diameter is 0.40-0.65mm.

[0038] Mix all kinds of raw materials evenly to get the repair material.

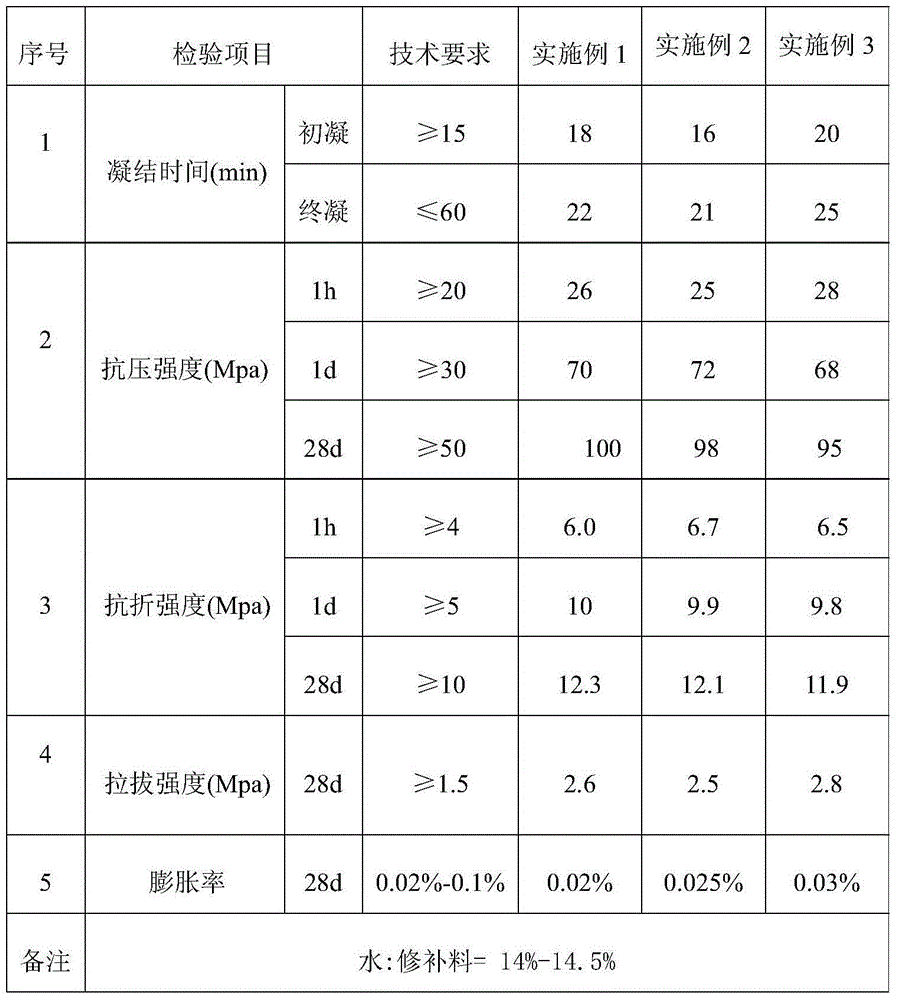

[0039] The properties of the repairing materials prepared in Examples 1-3 were measured, as shown in the table below.

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com