Synthetic method for monodispersed cobalt dioxide nanocrystalline

A cobaltous oxide nanometer and synthesis method technology, which is applied in the field of synthesis of inorganic compounds, can solve problems such as high cost, complicated process, and difficult control of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

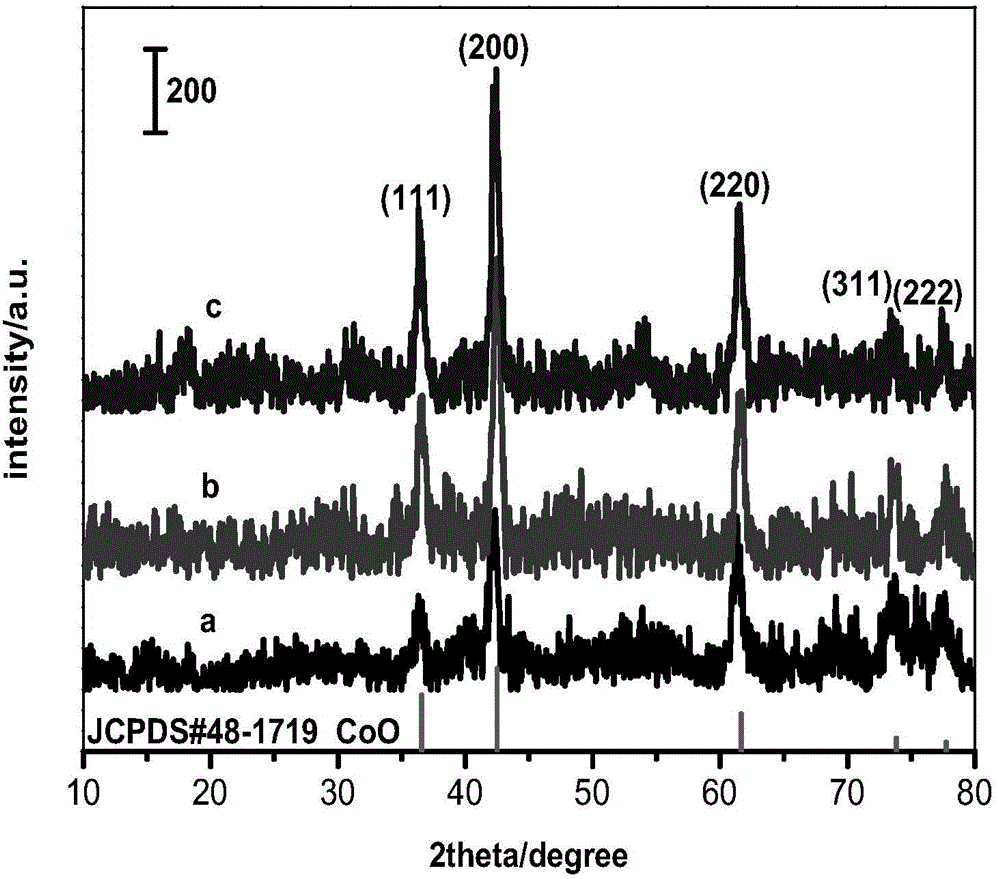

Embodiment 1

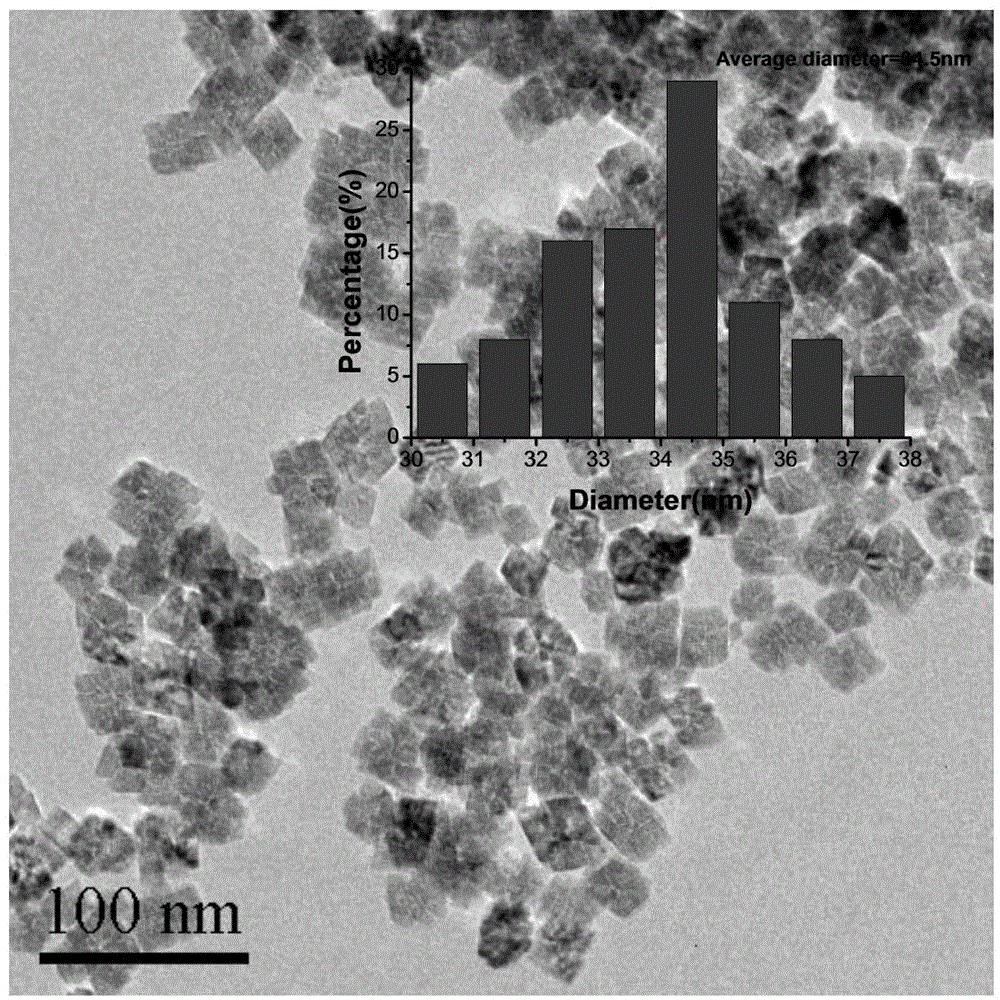

[0035] Under the mixed atmosphere of hydrogen and argon (the hydrogen gas fraction is 10%, the mixed gas flow rate is 40ml / min), put 56mmol dodecylamine (10.4g) and 0.56mmol cobalt (III) acetylacetonate (0.2g) into the three-neck Mix the flask, heat to 80°C in an oil bath for 8 minutes to dissolve cobalt(III) acetylacetonate in dodecylamine to form a uniform reddish-brown solution, then raise the temperature to 200°C and reflux for 1.5h at a heating rate of 10°C / min.

[0036] Stop heating, centrifuge when the solution is cooled to 70°C, and remove the supernatant. The obtained reddish-brown solid was washed with ethanol for 3 times, each time using 15 ml. The collected solid was transferred to a crucible, placed in an oven, and dried at 60° C. for 5 h to obtain the product with a yield of 100%.

Embodiment 2

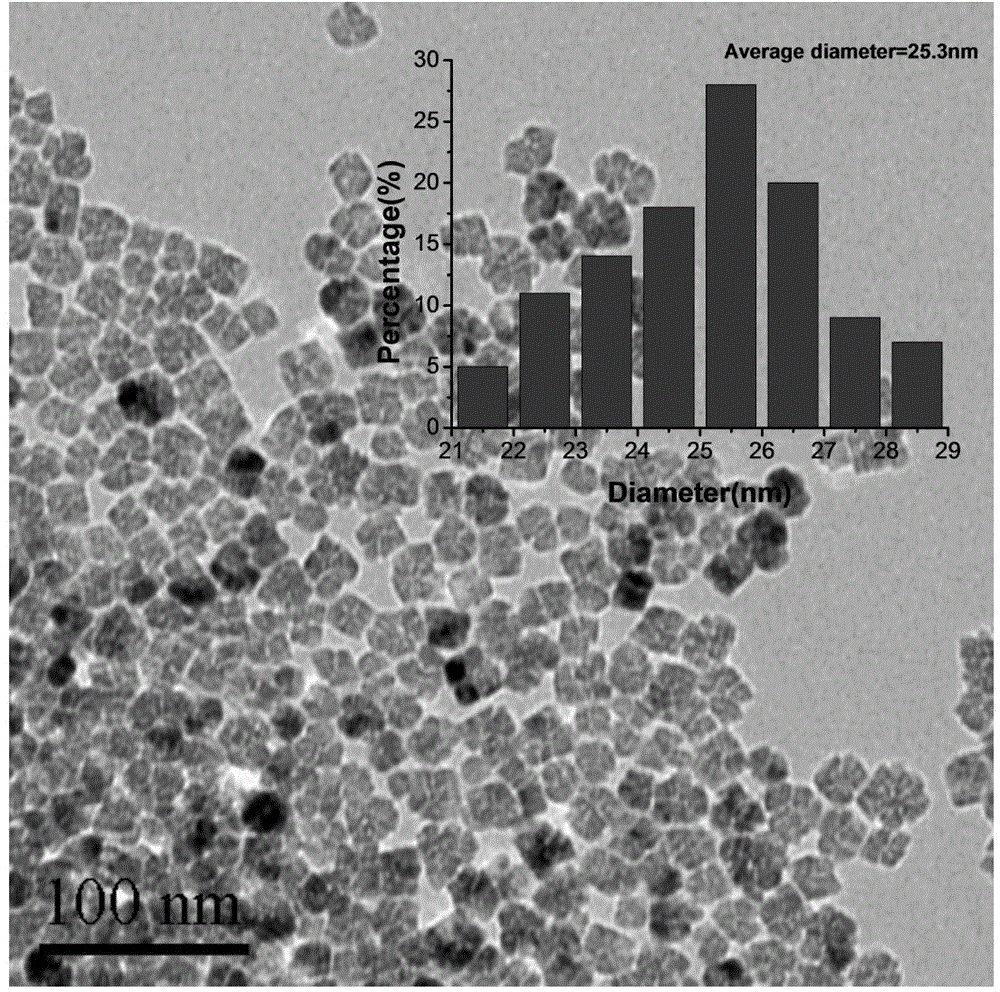

[0038] Under the mixed atmosphere of hydrogen and argon (hydrogen gas fraction is 20%, mixed gas flow rate 40ml / min), 56mmol tetradecylamine (12g) and 5.6mmol cobalt (II) acetylacetonate (1.44g) are put into three-necked flask Mix and heat to 100°C in an oil bath for 2 minutes to dissolve cobalt(II) acetylacetonate in tetradecylamine to form a uniform reddish-brown solution, then raise the temperature to 200°C and reflux for 3 hours at a heating rate of 10°C / min.

[0039] Stop heating, centrifuge when the solution is cooled to 70°C, and remove the supernatant. The obtained reddish-brown solid was washed with ethanol for 3 times, each time using 15 ml. The collected solid was transferred to a crucible, placed in an oven, and dried at 60° C. for 5 h to obtain the product with a yield of 100%.

Embodiment 3

[0041]Under the mixed atmosphere of hydrogen and argon (hydrogen gas fraction is 40%, mixed gas flow rate 40ml / min), 56mmol octadecylamine (15.1g) and 2.24mmol cobalt (II) acetylacetonate (0.576g) are put into the three neck Mix the flask, heat to 100°C in an oil bath for 2 minutes to dissolve cobalt(II) acetylacetonate in octadecylamine to form a uniform reddish-brown solution, then raise the temperature to 200°C and reflux for 1.5h at a heating rate of 10°C / min.

[0042] Stop heating, centrifuge when the solution is cooled to 70°C, and remove the supernatant. The obtained reddish-brown solid was washed with ethanol for 3 times, each time using 15 ml. The collected solid was transferred to a crucible, placed in an oven, and dried at 60° C. for 5 h to obtain the product with a yield of 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com