a high co 2 Preparation method of nitrogen-rich hierarchical porous carbon with capture capacity and high specific capacitance

A technology with high specific capacitance and hierarchical pores, which is applied in the field of preparation of hierarchical porous carbons, can solve the problems of single performance of hierarchical porous carbons and failure to have high CO at the same time, and achieve the effect of mild preparation conditions and easy and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

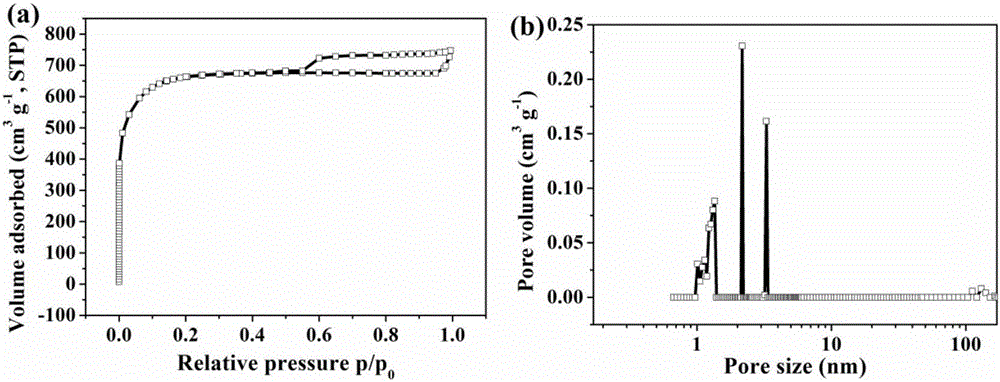

Embodiment 1

[0026] At room temperature, add 0.1 mol of cystine and 2.0 mol of formaldehyde solution with a mass fraction of 37 to 40% into a three-necked flask equipped with a condenser, a thermometer and a stirrer, and adjust the pH value of the solution with 0.5M triethanolamine solution 8.0, heated up to 90°C and stirred for 0.5h, then cooled naturally to room temperature to obtain solution A; dissolved 0.005mol of F127 and 0.5mol of m-cyanophenol in absolute ethanol, stirred in a water bath at 40°C for 2h, recorded It is solution B; add solution A to solution B and transfer to a three-necked flask, mix and stir at room temperature for 0.5h, keep stirring and react at reflux temperature for 5h, and then pour the solution into the dispersed 1.19g graphene oxide aqueous solution 0.1 mg / mL polyvinylpyrrolidone was added, stirred thoroughly for 1 h, and then ultrasonically dispersed for 2 h to obtain a uniformly dispersed graphene oxide composite. The graphene oxide-containing composite wa...

Embodiment 2

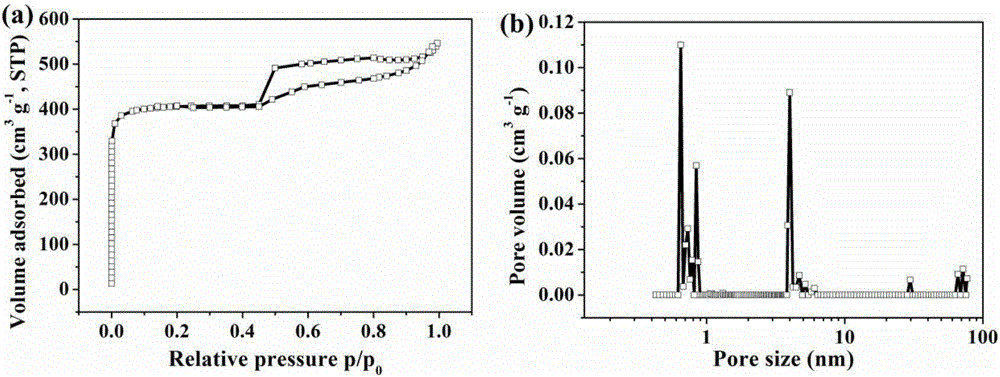

[0030] At room temperature, add 0.2 mol of melamine and 2.4 mol of formaldehyde solution with a mass fraction of 37 to 40% into a three-necked flask with a condenser, a thermometer and a stirrer, and adjust the pH of the solution to 9.0 with a 0.5M triethanolamine solution , raised the temperature to 50°C and stirred for 2 hours, then cooled naturally to room temperature to obtain solution A; dissolved 0.008mol of P123 and 0.4mol of 1,6-dihydroxynaphthalene in absolute ethanol, stirred in a water bath at 60°C for 1h, recorded It is solution B; add solution A to solution B and transfer to a three-necked flask, mix and stir at room temperature for 1 hour, keep stirring and react at reflux temperature for 2 hours, and then pour the solution into 1.29 g of dispersed graphene oxide aqueous solution , and 0.1 mg / mL polyvinyl pyrrolidone was added, stirred thoroughly for 2 hours and then ultrasonically dispersed for 6 hours to obtain a uniformly dispersed graphene oxide composite. Th...

Embodiment 3

[0034]At room temperature, add 0.2 mol of melamine and 1.5 mol of formaldehyde solution with a mass fraction of 37 to 40% into a three-necked flask with a condenser, a thermometer and a stirrer, and adjust the pH of the solution to 8.5 with a 0.5M triethanolamine solution , heated to 65°C and stirred for 1 hour, then cooled naturally to room temperature to obtain solution A; dissolved 0.004mol of P123 and 0.5mol of m-cyanophenol in absolute ethanol, stirred in a water bath at 50°C for 1.5h, and recorded as solution B; Add solution A to solution B and transfer to a three-necked flask, mix and stir at room temperature for 0.75h, then insulate and stir at reflux temperature for 3h, then pour the solution into a dispersed 0.42g graphene oxide aqueous solution, And add 0.1mg / mL polyvinylpyrrolidone, stir thoroughly for 1.5h, then ultrasonically disperse for 4h to obtain a uniformly dispersed graphene oxide composite. The graphene oxide-containing composite was transferred to an ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com