Plate-type structural component machining method

A processing method and technology for structural parts, which are applied in the field of forging and processing of plate parts, can solve the problems of unqualified shape and position tolerance of the mounting surface, low processing efficiency, poor quality of the mounting surface, etc., and achieve the improvement of cutting parameters and tool path path design. Part quality, the effect of solving part deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

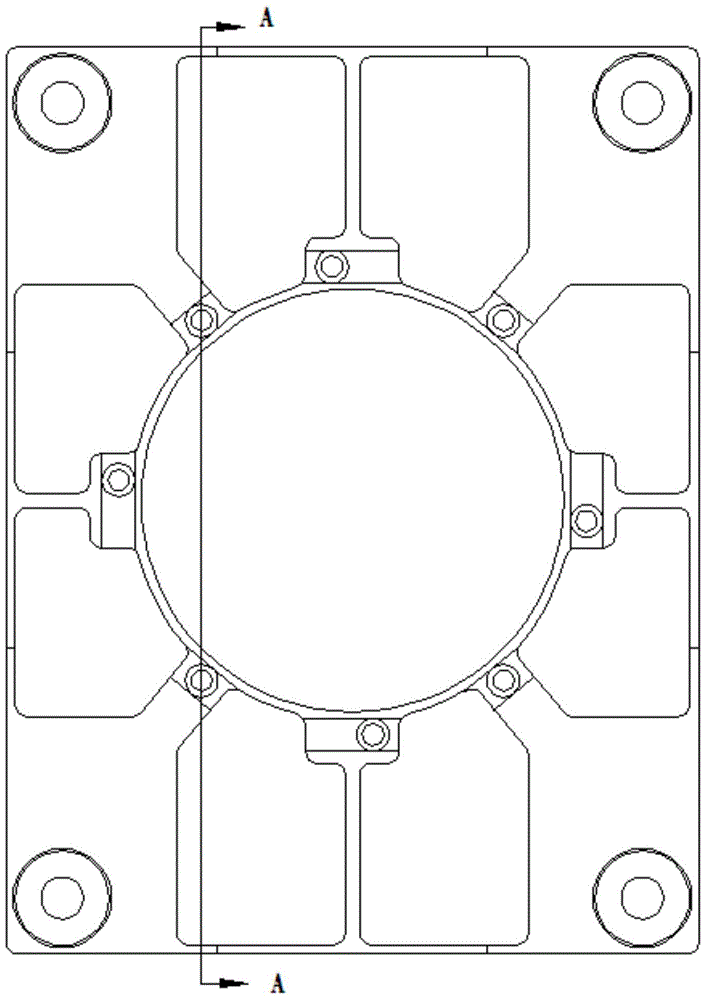

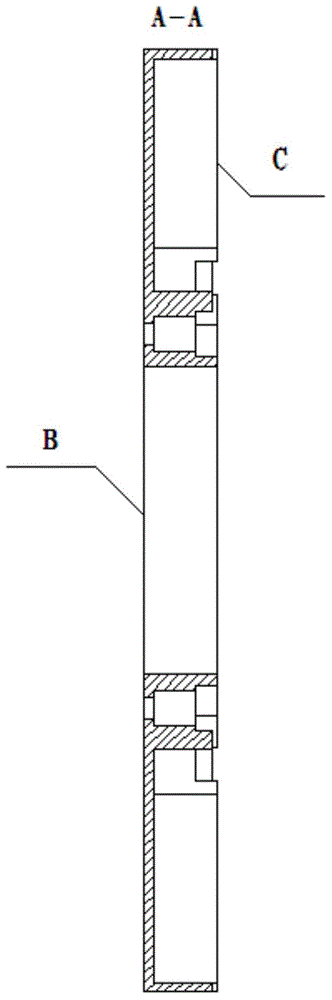

[0030] The embodiment of the present invention provides a processing method for plate structural parts, including: processing process design, processing allowance distribution, numerical control milling and micro-boring cutting;

[0031] The process flow design includes:

[0032] Roughly mill the inner shape, leaving a margin of 2mm;

[0033] Eliminate stress during processing by artificial aging;

[0034] Finish milling inside and outside, leaving 0.15mm~0.2mm boring allowance on the mounting surface;

[0035] Fine boring datum surface and mounting surface to ensure various shape and position tolerances;

[0036] Manual grinding assists fine boring, removes local high points of datum surface and installation surface;

[0037] The machining allowance distribution includes:

[0038] The amount of rough machining material removal is not less than 85%, and the rough machining allowance is 2mm;

[0039] The inner and outer shapes are finished to the same size, with a margin o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com