Polymer exhaust for eliminating extruder transients

a technology of extruder transient and polymer, which is applied in the direction of additive manufacturing processes, manufacturing tools, and applying layer means, etc., can solve the problems of uneven surface of parts, uneven extrusion rate, and uneven extrusion rate, so as to improve resolution and reduce post-processing of baam parts , the effect of improving print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The present invention provides methods for making an article with an additive manufacturing machine wherein working material is deposited on a deposit surface to form an article constructed from multiple or iterative layers or additions of such material.

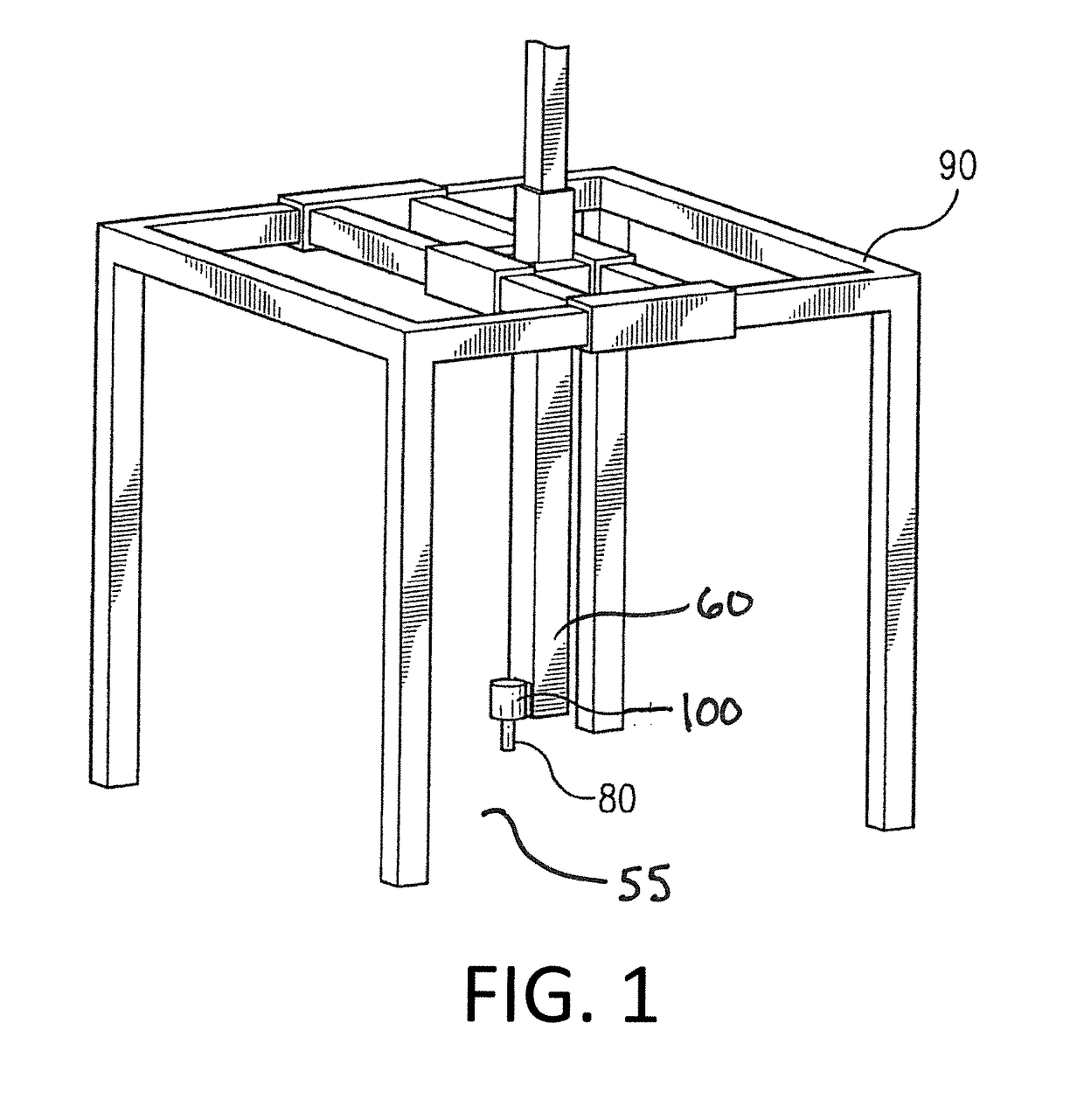

[0015]Although not required, the subject invention is preferably used in connection with large scale polymer added manufacturing, also termed “big area additive manufacturing” or BAAM, such as the schematic shown in FIG. 1. FIG. 1 shows a frame or gantry 90 for containing a build on surface 55. The gantry 90 preferably contains a deposition arm 60 that is moveable through the x, y and z-axis, via a controller (not shown). The deposition arm 60 preferably accommodates a supply of working material and a deposition nozzle 80. The supply of working material may be onboard the deposition arm 60 and / or remotely supplied from a hopper or similar storage vessel.

[0016]Although generally referenced herein as “molten material” or “polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| residual pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com