Processing method of aluminum-silicon shell

A processing method and shell technology, applied in the direction of metal processing equipment, workpieces, manufacturing tools, etc., can solve the problems that restrict the promotion and application of the packaging shell field, prone to chipping, high brittleness, etc., and achieve the improvement of the subsequent coating layer Quality, avoiding edge collapse, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

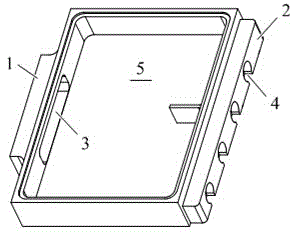

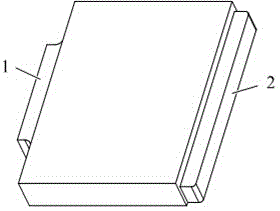

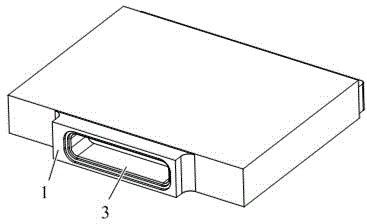

[0020] like figure 1 As shown, the aluminum-silicon housing has an inner cavity 5 with an upward opening for placing electronic components, a first boss 1 is provided on the left side of the housing, and a second boss 2 is provided on the right side of the housing. A rectangular stepped hole 3 for communicating with the inner cavity is opened on the first boss, and a plurality of circular stepped holes 4 are successively opened on the second boss along its length direction.

[0021] The concrete steps of aluminum-silicon shell processing method of the present invention comprise as follows:

[0022] Step 1: Use a φ6 or φ8 alloy coated end mill, set the speed within the range of 3500-4500 RPM, set the feed within the range of 450-550 mm / min, and mill the shell shape, the shape includes The top surface, the bottom surface and the surrounding ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com