A wear-resistant and anti-clogging permanent magnet wet coarse pre-selection magnetic separator

An anti-clogging, magnetic separator technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the lack of pulping process or insufficient pulping, unfavorable ore feeding, sorting, poor bonding strength, etc. problems, to achieve the effects of separation, large gradient, and not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

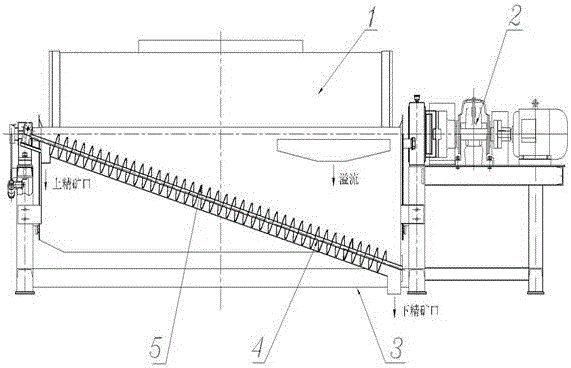

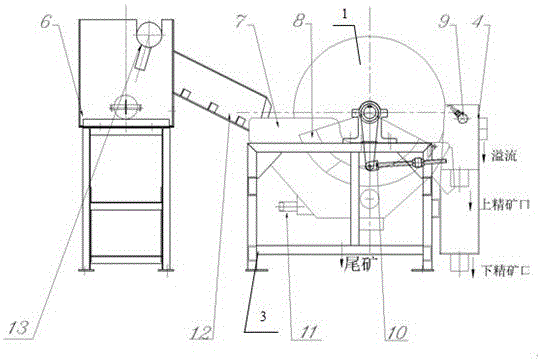

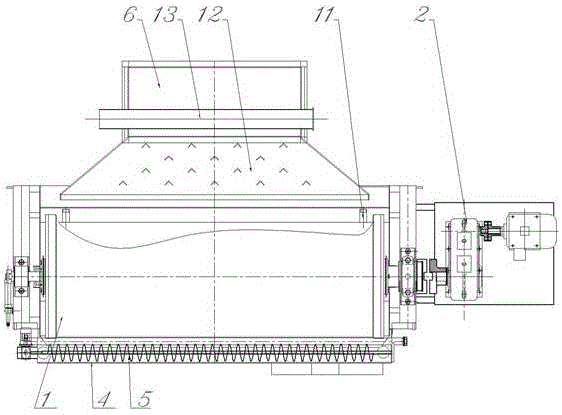

[0030] In order to better describe the present invention, a wear-resistant and anti-clogging permanent magnet wet coarse pre-selection magnetic separator of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] Depend on figure 2 Shown is a kind of wear-resistant and anti-clogging permanent magnet wet-type coarse-grain pre-selection magnetic separator of the present invention, which is a schematic diagram of the left sectional structure and combined with figure 1 , image 3It can be seen that a kind of wear-resistant and anti-clogging permanent magnet wet type coarse pre-selection magnetic separator of the present invention is composed of cylinder body 1, driving device 2, frame 3, concentrate box 4, forced ore unloading device 5, ore feeding device, The tank body 7, the magnetic system 8, the ore unloading flushing water pipe 9, the magnetic adjustment device 10, etc. are organically combined to form a struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com