A preparation method of graphite carbon nitride composite nickel ferrite magnetic photocatalytic material

A graphite-type carbon nitride and photocatalytic material technology, which is applied in the field of photocatalysis, can solve the problems of difficult recovery of nickel ferrite carbon nitride, achieve high activity and stability, help recycling, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: 5.7 mg of graphite carbon nitride and 114.3 mg of nickel ferrite were added into 20 ml of absolute anhydrous ethanol, stirred and dispersed for 8 hours, and then heat-treated in an oven at 50° C. for 16 hours to obtain the photocatalyst.

[0026] Take 50mg of the catalyst obtained in Example 1 and add it to 50ml of methylene blue (10mg / l), stir magnetically in a constant temperature water bath at 30°C and let in air, add hydrogen peroxide after dark reaction for 1 hour, and use a 300w lamp equipped with an ultraviolet filter A visible light source was used to irradiate the system, and 4 ml of the suspension was taken every 30 minutes and centrifuged to test the absorbance.

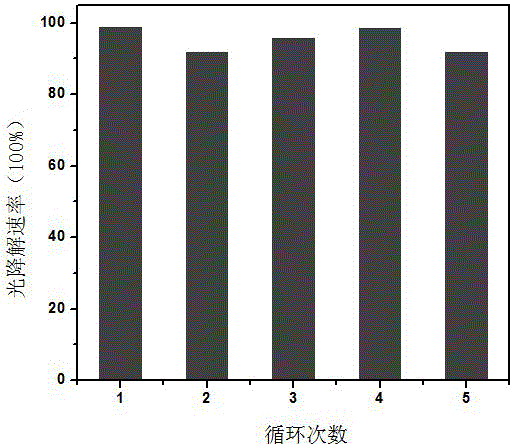

[0027] The graphene-like carbon nitride / nickel ferrite composite photocatalyst prepared by embodiment 1 has a degradation rate of 66% to methylene blue in 4 hours, as image 3 .

Embodiment 2

[0028] Example 2: 8.5 mg of graphite carbon nitride and 111.5 mg of nickel ferrite were added into 20 ml of absolute anhydrous ethanol, stirred and dispersed for 10 hours, and then heat-treated in an oven at 110° C. for 10 hours to obtain the photocatalyst.

[0029] Take 50mg of the catalyst obtained in Example 2 and add it to 50ml of methylene blue (10mg / l), stir magnetically in a constant temperature water bath at 30°C and let in air, add hydrogen peroxide after dark reaction for 1 hour, and use a 300w UV filter installed at the same time A visible light source was used to irradiate the system, and 4 ml of the suspension was taken every 30 minutes and centrifuged to test the absorbance.

[0030] The graphene-like carbon nitride / nickel ferrite composite photocatalyst prepared by embodiment 2 has a degradation rate of 87% to methylene blue in 4 hours, as Figure 4 , the activity of the composite photocatalyst is the highest when the mass ratio is 1:13-14.

Embodiment 3

[0031] Example 3: 10.9 mg of graphite carbon nitride and 109.1 mg of nickel ferrite were added into 20 ml of absolute anhydrous ethanol, stirred and dispersed for 12 hours, and then heat-treated in an oven at 150° C. for 8 hours to obtain the photocatalyst.

[0032] Take 50mg of the catalyst obtained in Example 3 and add it to 50ml of methylene blue (10mg / l), stir magnetically in a constant temperature water bath at 30°C and let in air, add hydrogen peroxide after dark reaction for 1 hour, and use a 300w lamp equipped with an ultraviolet filter A visible light source was used to irradiate the system, and 4 ml of the suspension was taken every 30 minutes and centrifuged to test the absorbance.

[0033] The graphene-like carbon nitride / nickel ferrite composite photocatalyst prepared by embodiment 3 has a degradation rate of 76% to methylene blue in 4 hours, as Figure 5 .

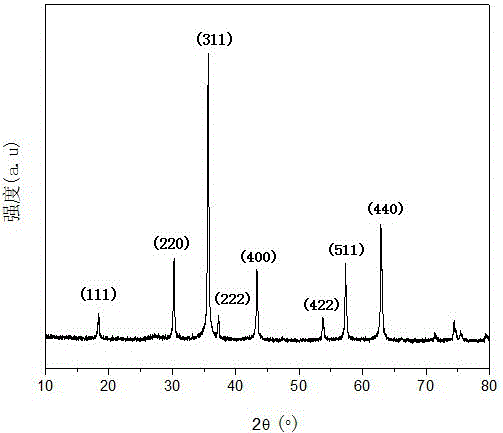

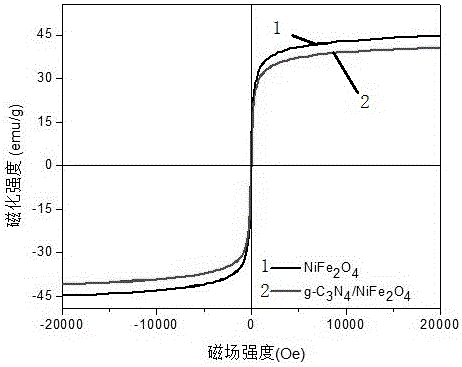

[0034] figure 1 For the X-ray diffraction spectrum of the graphite carbon nitride / nickel ferrite compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com