BixCel-xVO4 nanorod with visible-light activity and preparation method

A nanorod and visible light technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of limited development, poor stability of vanadate compounds, and easy photocorrosion, etc., and is easy to operate and conducive to adsorption. Degradation, the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

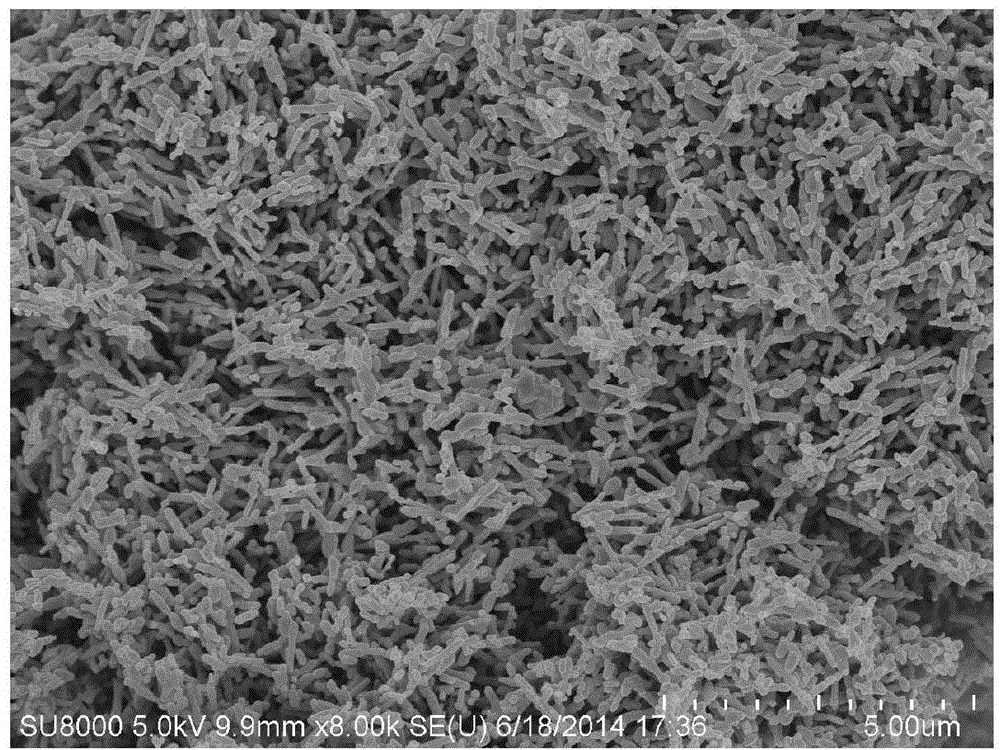

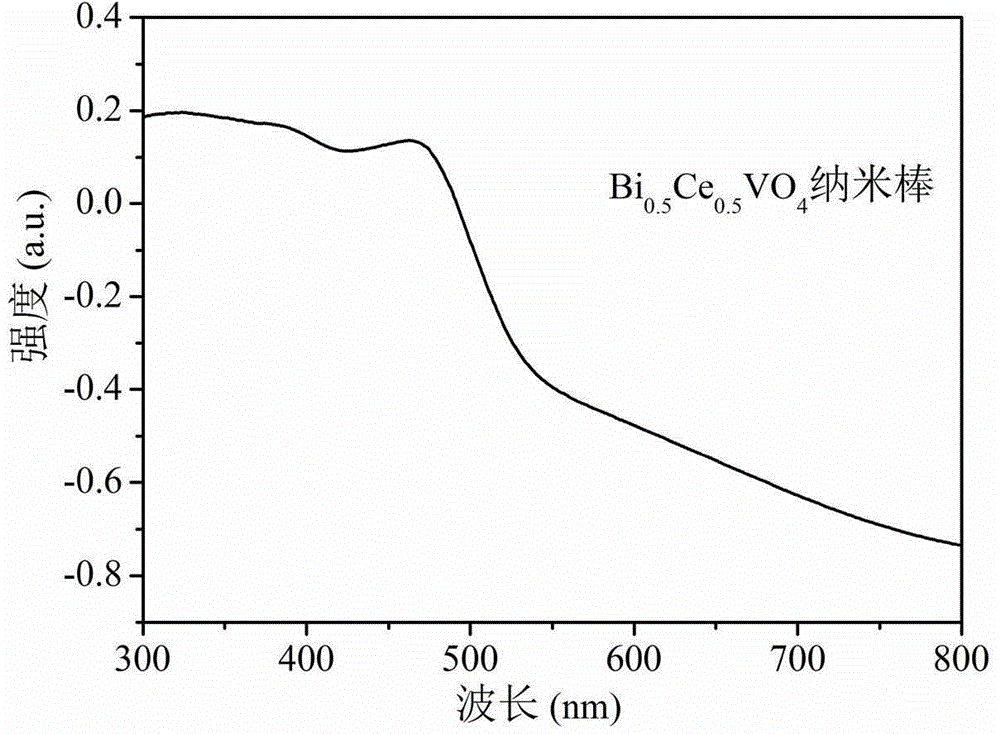

[0027] 1.84g Bi(NO 3 ) 3 ·5H 2 O and 1.63g Ce(NO 3 ) 3 ·6H 2 O powder was dissolved in 50mL water, stirred at room temperature for 30min, and ultrasonicated for 30min to obtain A solution; add 0.88g of NH 4 VO 3Add 50mL of water, dissolve in a water bath at 60°C, and stir for 30min to obtain solution B. Solution A was added dropwise to solution B under stirring to obtain a yellow clear liquid. The mixed solution was transferred to a 120mL autoclave lined with polytetrafluoroethylene, hydrothermally reacted at 147.4kPa and 160°C for 3h, and cooled naturally to room temperature. Centrifuge and collect the light yellow precipitate at the bottom, wash the precipitate with deionized water and ethanol in turn, dry the precipitate in a 60°C drying oven, and grind it into fine particles. The dried sample was heated up to 500°C at 10°C / min, and calcined at 500°C for 24 hours, and the obtained light yellow powder was Bi 0.5 Ce 0.5 VO 4 Nanorods, from figure 1 Bi can be clear...

Embodiment 2

[0029] 0.34g Bi(NO 3 ) 3 ·5H 2 O and 2.61g Ce(NO 3 ) 3 ·6H 2 O powder was dissolved in 50mL water, stirred at room temperature for 30min, and ultrasonicated for 15min to obtain A solution; add 0.88g of NH 4 VO 3 Add 50mL of water, dissolve in a water bath at 60°C, and stir for 30min to obtain solution B. Solution A was added dropwise to solution B under stirring to obtain a yellow clear liquid. The mixed solution was transferred to a 120mL autoclave lined with polytetrafluoroethylene, hydrothermally reacted at 133.7kPa and 120°C for 6h, and cooled naturally to room temperature. Centrifuge and collect the light yellow precipitate at the bottom, wash the precipitate with deionized water and ethanol in turn, dry the precipitate in a 60°C drying oven, and grind it into fine particles. The dried sample was heated up to 800°C at 10°C / min, and calcined at 800°C for 12 hours, and the obtained light yellow powder was Bi 0.2 Ce 0.8 VO 4 Nano stave.

Embodiment 3

[0031] 2.84g Bi(NO 3 ) 3 ·5H 2 O and 0.65g Ce(NO 3 ) 3 ·6H 2 O powder was dissolved in 50mL water, stirred at room temperature for 30min, and ultrasonicated for 60min to obtain A solution; add 0.88g of NH 4 VO 3 Add 50mL of water, dissolve in a water bath at 60°C, and stir for 30min to obtain solution B. Solution A was added dropwise to solution B under stirring to obtain a yellow clear liquid. The mixed solution was transferred to a 120mL autoclave lined with polytetrafluoroethylene, hydrothermally reacted at 161.1kPa, 200°C for 1h, and cooled naturally to room temperature. Centrifuge and collect the light yellow precipitate at the bottom, wash the precipitate with deionized water and ethanol in turn, dry the precipitate in a 60°C drying oven, and grind it into fine particles. The dried sample was heated up to 300°C at 10°C / min, and calcined at 300°C for 48 hours, and the obtained light yellow powder was Bi 0.8 Ce 0.2 VO 4 Nano stave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com