Method for producing antimicrobial-free feed through enzymosis and fermentation of straw

An antibiotic-free feed and enzymatic hydrolysis technology, applied in animal feed, animal feed, application, etc., can solve the problems of restricting the utilization range of straw raw materials, high straw crude fiber content, and low utilization of nutrients, so as to shorten the fermentation cycle and biotransformation The effect of high yield and short fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

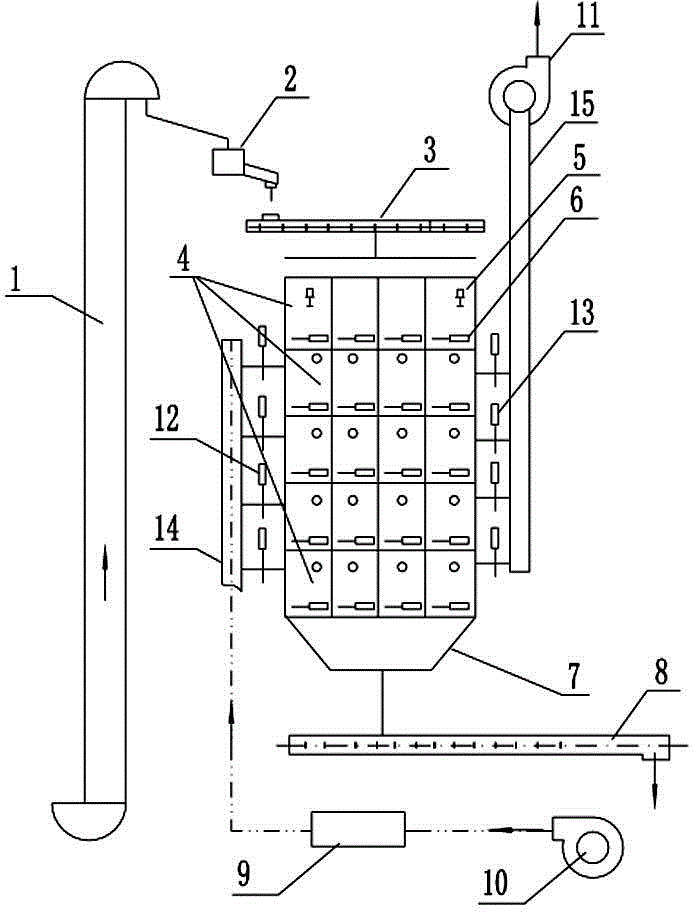

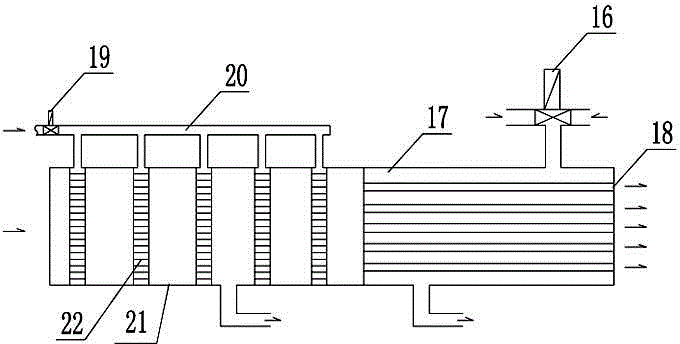

Image

Examples

Embodiment 1

[0060] The method for producing non-resistant feed for fattening pigs by enzymatic hydrolysis and fermentation of straw of the present invention includes the following steps:

[0061] The first step, liquid fermentation

[0062] The specific preparation methods of the fermentation broth of Corynebacterium glutamicum, the fermentation broth of Candida tropicalis, the fermentation broth of Bacillus natto, the fermentation broth of Lactobacillus plantarum and the fermentation broth of Aspergillus oryzae are the same as the specific embodiments, and the above five fermentation broths are The ratio of 6:1:1:1:2 is made into a mixed bacterial liquid for later use;

[0063] The second step, solid enzymatic hydrolysis and fermentation

[0064] a. Put 150 parts of corn stalks, 480 parts of corn, 50 parts of guar meal, 80 parts of DDGS, 6.8 parts of calcium oxide, and mix them into the explosion tank with a charging coefficient of 60-80%. The explosion tank can be opened after being sealed. F...

Embodiment 2

[0078] The method for producing non-resistant feed for laying hens by enzymatic hydrolysis and fermentation of straw of the present invention includes the following steps:

[0079] The first step, liquid fermentation

[0080] The specific preparation methods of the fermentation broth of Corynebacterium glutamicum, the fermentation broth of Candida tropicalis, the fermentation broth of Bacillus natto, the fermentation broth of Lactobacillus plantarum and the fermentation broth of Aspergillus oryzae are the same as the specific embodiments, and the above five fermentation broths are The ratio of 6:2:1:1:1 is made into a mixed bacterial liquid for later use;

[0081] The second step, solid enzymatic hydrolysis and fermentation

[0082] a. Put 150 parts of corn stalks, 480 parts of corn, 120 parts of cotton meal, 80 parts of rapeseed meal, 80 parts of DDGS, 11 parts of calcium oxide, and mix them into the explosion tank, the charging coefficient is 60~80%, the explosion tank After the b...

Embodiment 3

[0096] The method for producing non-resistant feed for laying ducks by enzymatic hydrolysis and fermentation of straw of the present invention includes the following steps:

[0097] The first step, liquid fermentation

[0098] The specific preparation methods of the fermentation broth of Corynebacterium glutamicum, the fermentation broth of Candida tropicalis, the fermentation broth of Bacillus natto, the fermentation broth of Lactobacillus plantarum and the fermentation broth of Aspergillus oryzae are the same as the specific embodiments, and the above five fermentation broths are The ratio of 6:1:1:1:1 is made into mixed bacteria liquid for later use;

[0099] The second step, solid enzymatic hydrolysis and fermentation

[0100] a. Put 150 parts of corn stalks, 400 parts of corn, 160 parts of cotton meal, 100 parts of rapeseed meal, and 8.1 parts of calcium oxide into the explosion tank after mixing, the charging coefficient is 60~80%, the explosion tank body is sealed Enter satur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com