Separator for aluminium electrolytic capacitor, and aluminium electrolytic capacitor

A technology of aluminum electrolytic capacitors and diaphragms, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of increased paper density and deterioration of impedance characteristics, and achieve the effect of excellent short-circuit resistance and miniaturization of capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

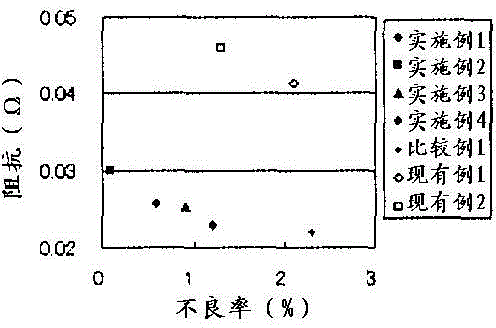

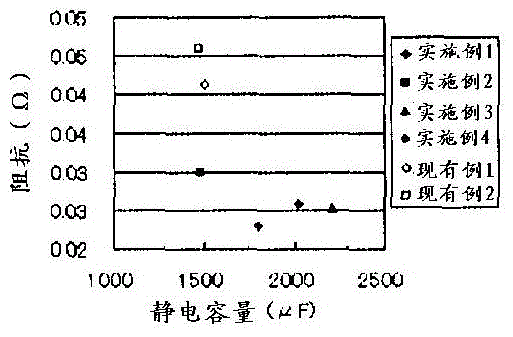

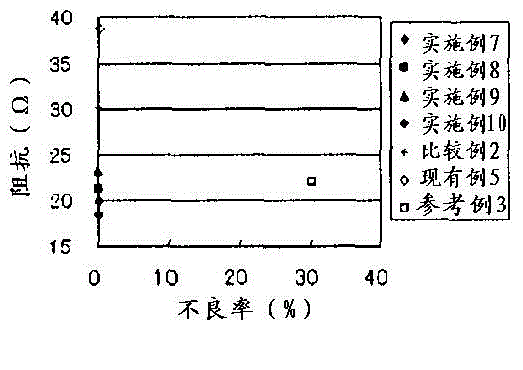

Examples

Embodiment 1

[0107] TCF linter pulp with a degree of polymerization of 1500 was used to prepare a cellulose / NMMO solution composed of cellulose / NMMO=10 / 90. The obtained cellulose / NMMO solution was extruded using a T-die extruder with a slit of 0.05mm. After passing through an air gap of 10mm, it was dipped in a poor solvent coagulation bath of 20% by weight of NMMO to regenerate cellulose. . The regenerated cellulose was washed with a three-tank ion-exchange water washing bath, and then freeze-dried to a thickness of 28.1 μm and a density of 0.11 g / cm 3 , average pore diameter 4.53μm, weight per square meter 3.1g / m 2 , A cellulose porous membrane with a chlorine content of 0.2 ppm and a sulfate content of 1.7 ppm.

Embodiment 2

[0109] TCF with a degree of polymerization of 800 was used to dissolve the pulp to obtain a cellulose / NMMO solution composed of cellulose / NMMO=5 / 95. In the obtained cellulose / NMMO solution, add polymethyl methacrylate particles with a diameter of 5 μm to an amount of 200% by weight relative to the cellulose, and after uniformly dispersing, use a T-die type extrusion molding machine, and use a 0.2 mm The slit width is extruded, and after passing through an air gap of 10 mm, it is dipped in a poor solvent coagulation bath of 20% by weight of NMMO to regenerate cellulose. The regenerated cellulose was washed with a 3-tank ion-exchanged water washing bath, then dissolved and removed with a 3-tank acetone bath to remove polymethyl methacrylate particles, and after solvent replacement was performed with a 3-tank isopropanol bath, the Dried in a type dryer to obtain a thickness of 51.2 μm and a density of 0.19 g / cm 3 , average pore diameter 2.96μm, weight per square meter 9.7g / m 2 ...

Embodiment 3

[0111] TCF with a degree of polymerization of 800 was used to dissolve the pulp to obtain a cellulose / NMMO solution composed of cellulose / NMMO=3 / 97. Silicon particles with a diameter of 1 μm were added to the obtained cellulose / NMMO solution to 100% by weight relative to the cellulose, and glycerol as a plasticizer was added to 1% by weight relative to the cellulose. After uniform dispersion, the T-die method was used to The extruder is extruded with a slit width of 0.1 mm, and after passing through an air gap of 10 mm, it is dipped in a poor solvent coagulation bath of 20% by weight of NMMO to regenerate cellulose. The regenerated cellulose was washed with 3 tanks of ion-exchanged water baths, dissolved and removed with 3 tanks of 30% by weight potassium hydroxide aqueous solution to remove silicon particles, washed with 3 tanks of ion-exchanged water baths, and dried by drum Machine to dry, made thickness 5.5μm, density 0.72g / cm 3 , average pore size 0.15μm, weight per squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com