Green printing fountain solution and preparation method thereof

A fountain solution, green technology, applied in the field of printing fountain solution, can solve the problem that volatiles are difficult to adapt to energy saving and emission reduction, and achieve the effect of surface cleaning, emission reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Preparation of fountain solution

[0019] A green printing dampening solution prepared from the following components by weight (kg): Camellia oleifera seed cake 20, aluminum oxide 1.5, sodium bicarbonate 2, potassium hydroxide 0.4, sodium stearate 2, spermaceti Polydimethylsiloxane 0.8, Isooctyl Hexadecanoate 3, Sucrose Monolaurate 3, Gamma-Polyglutamic Acid 2, Chitosan 6, Tartaric Acid 3, Methylparaben 0.8, Additive 8, water 50;

[0020] Among them, the auxiliary agent is made of the following raw materials by weight (kg): sodium tripolyphosphate 1.5, polyethylene glycol 2, sodium alginate 1.5, chitosan 7, gelatin 6, citric acid 2, sage oil 1.5, white carbon Black 0.8, sodium citrate 20, talcum powder 0.4, water 50; dissolve citric acid, sodium citrate, sodium alginate, chitosan, gelatin and sodium tripolyphosphate in water, first stir at 800r / min for 15min, then add Stir the remaining raw materials at 60°C for 15 minutes, filter after cooling, and obta...

Embodiment 2

[0024] Embodiment 2: the mensuration of ink emulsification rate

[0025] Offset printing requires moderate emulsification of the ink during the printing process, but too high an emulsification rate will affect the balance of water and ink, resulting in poor offset printing effect. According to the principle of printing water-ink balance, ink emulsification should form a W / O emulsion, which is beneficial to compete with the ink on the printing plate with the least amount of liquid supply, so the ink emulsification rate should be controlled below 26%.

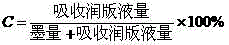

[0026] Determination of ink emulsification rate C: by weight method.

[0027] Dilute the dampening solution in Example 1 to 5% with distilled water, add 15g of lithographic printing black ink and 15g of diluted dampening solution to the container at one time, stir at 100r / min for 1h and then let it stand for 15min, and remove the unabsorbed dampening solution The plate liquid and the ink are separated in layers, weighed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com