A fully automatic shrapnel assembly device and its working method

An assembly equipment and fully automatic technology, applied in the direction of sorting, etc., can solve the problems of high activity, prolonging the production cycle, increasing labor costs, etc., to reduce the occupancy rate of space, reduce the generation of defective products, and reduce labor input cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

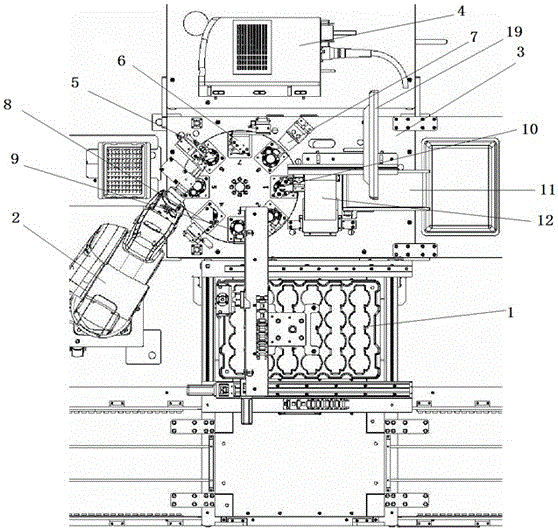

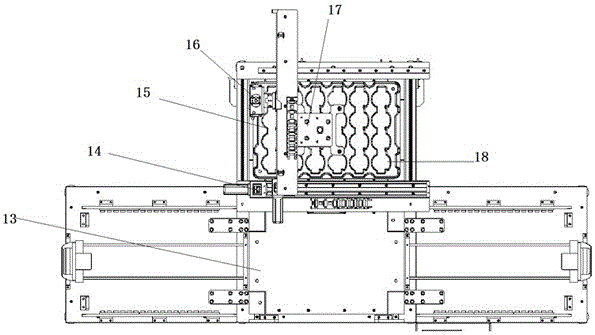

[0037] As shown in the figure, a fully automatic shrapnel assembly equipment includes: a body, a detection system, a control system and a finished product separation system, wherein the body is composed of an automatic feeding mechanism 1, a robot 2, a machine body 3, and a laser engraving machine 4 and the base, the detection system is composed of a pressure sensor 5, a displacement sensor 6 and a scanner 7, and the finished product separation system is composed of a positioning cylinder 8, a belt cylinder 9, a workstation 10, a good product channel 11 and a defective product channel 12, the automatic feeding mechanism 1 is composed of a loading tray 13, an X-direction servo motor 14, a Y-direction servo motor 15, a first cylinder 16, a second cylinder 17 and a blister tray 18.

[0038] The relationship between the above components is as follows:

[0039] The automatic feeding mechanism 1 is arranged above the base, the robot 2 is arranged on the side of the automatic feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com