Preparation method for supramolecular graphene load ferroferric oxide self-assembly body

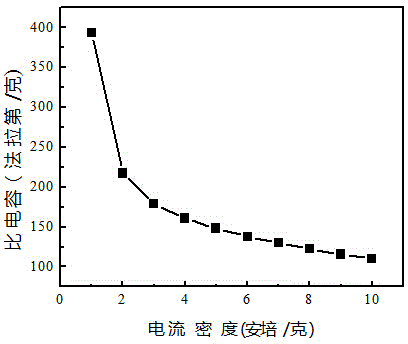

A technology of triiron tetroxide and iron tetroxide, which is applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of reduced specific surface, poor stability, low conductivity, etc. The effect of solving agglomeration and improving capacitance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Preparation of graphene three-dimensional self-assembly

[0025] 1. Preparation of water-soluble β-polycyclodextrin:

[0026] Add 20g of β-cyclodextrin (β-CD) into 30wt% NaOH aqueous solution and stir at room temperature until β-CD dissolves to obtain a mixture. After the mixture was placed in a 30°C water bath for 5 hours, 9.64 mL of epichlorohydrin was added to the mixture, stirred for 24 h, and cooled to room temperature. After the salt is removed by dialysis, the solution is evaporated to dryness to obtain a white solid, which is dried in vacuum for 24 hours (vacuum degree is 1200-4800 Pa, drying temperature is 50-70°C), and water-soluble β-CD polymer (β- polycyclodextrin).

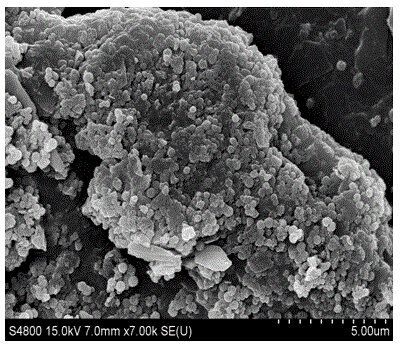

[0027] 2. Preparation of graphene-supported ferric oxide (rGOFe 3 o 4 ):

[0028] Disperse 10mg of graphite oxide powder into 10mL of ethylene glycol, and obtain a homogeneous solution by ultrasonication, then add 0.1g of polyvinylpyrrolidone, 0.2g of sodium acetate, and 0.108g of high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com