A capacitive ultra-thin flexible stress sensor and its preparation method

A stress sensor, capacitive technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of unstable performance of the interface between the composite material and the electrolyte, unable to achieve self-support, not discussing the stretching effect, etc. The method is simple and easy to implement, flexible and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

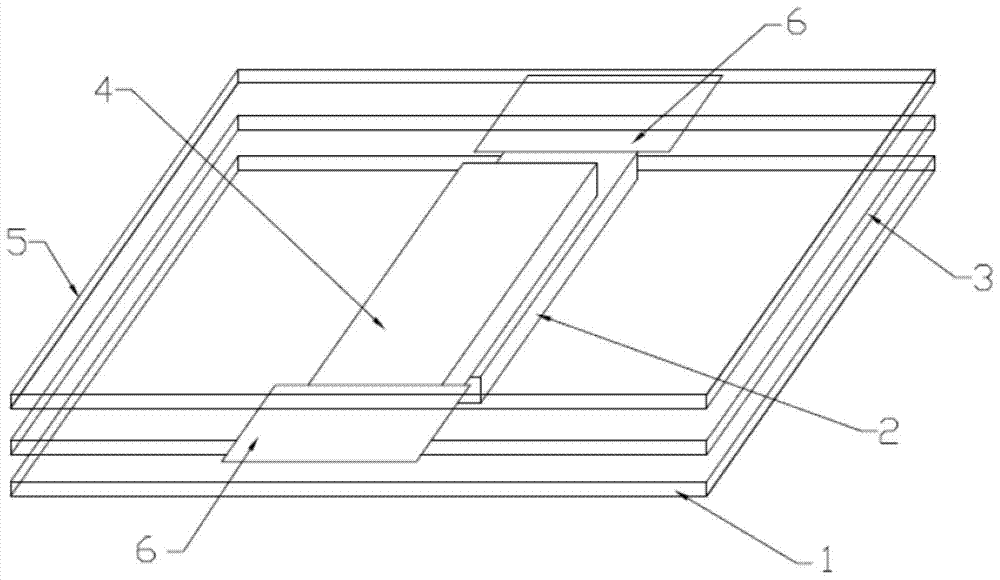

[0031] A method for preparing a capacitive ultra-thin flexible stress sensor is characterized in that it comprises the following steps:

[0032] 1) Cut a 50-micron thick polyurethane elastic film into three 3cm×5cm elastic films, which are used as the upper elastic protective film 5, the middle elastic insulating isolation film 3 and the lower elastic protective film 1 respectively;

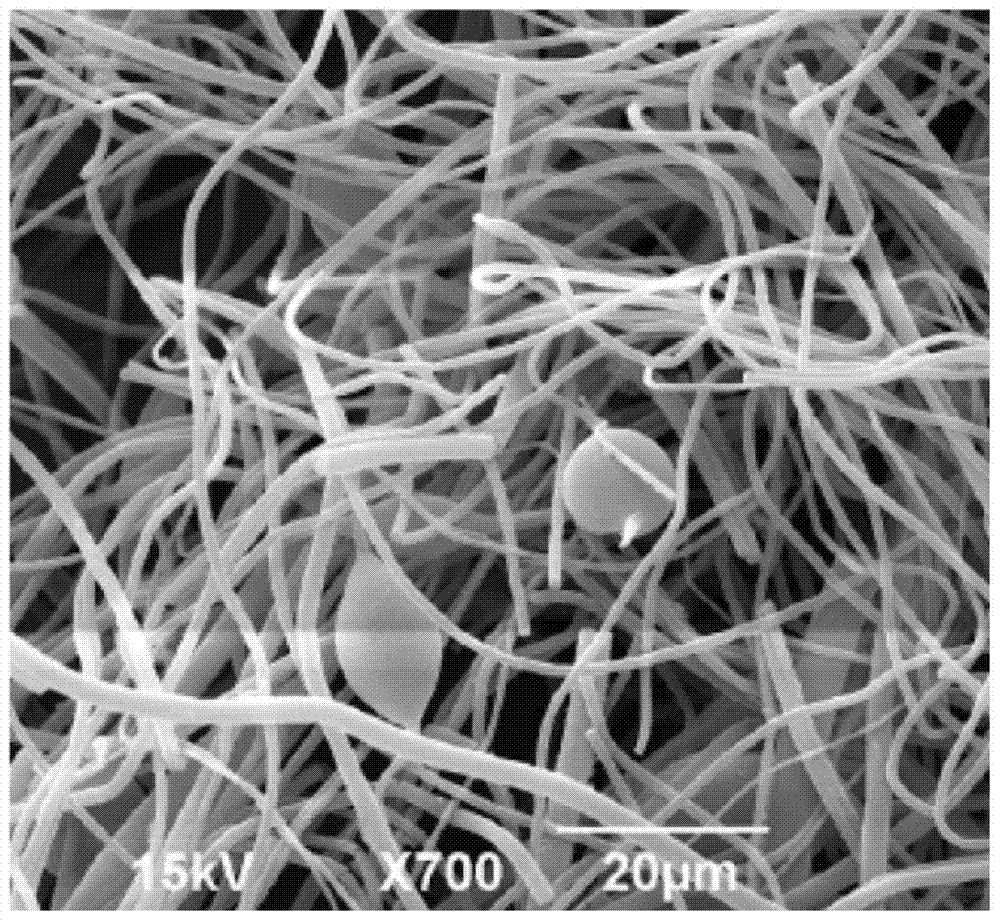

[0033] 2) Add 1.5 g of polyvinylidene fluoride particles with a molecular weight of 270,000 under magnetic stirring, add 6.2 g of a mixed solution of dimethyl sulfoxide and acetone (mass ratio 1:1), and heat and stir in a constant temperature water bath at 60°C for 1 hour. 18wt% polyvinylidene fluoride solution, mix 2 g of carbon nanotube dispersant with 16.8 g of acetone, the heating temperature of the water bath is 60 ℃, magnetic stirring for 10 minutes, add 1.2 g of multi-walled carbon nanotubes, and ultrasonically stir evenly A carbon nanotube dispersion liquid is formed, and 2.2 grams of the carb...

Embodiment 2

[0039] A method for preparing a capacitive ultra-thin flexible stress sensor is characterized in that it comprises the following steps:

[0040] 1) Cut a 100-micron thick polyurethane elastic film into three 5cm×5cm elastic films, which are used as the upper elastic protective film 5, the middle elastic insulating isolation film 3 and the lower elastic protective film 1 respectively;

[0041] 2) Mix 1.0 g of undoped intrinsic polyaniline with a molecular weight of 120,000 and 1.29 g of camphorsulfonic acid, and dissolve in 100 ml of chloroform under magnetic stirring at room temperature for 4 hours. Filter the resulting dark green solution (doped polyaniline), then add 32 mg of polyethylene oxide (molecular weight 2000000) to the filtrate, stir the solution magnetically for 2 hours at room temperature, and filter the solution again to obtain a uniform electrospun Silk precursor liquid; spray a layer of conductive nanofiber film on top of the lower elastic protective film 1 prepared...

Embodiment 3

[0047] A method for preparing a capacitive ultra-thin flexible stress sensor is characterized in that it comprises the following steps:

[0048] 1) Cut the 80 micron thick polyurethane elastic film into 3 3cm×2cm elastic films, which are used as the upper elastic protective film 5, the middle elastic insulating isolation film 3 and the lower elastic protective film 1 respectively;

[0049] 2) 1.0g of polyvinylpyrrolidone powder, 3.0g of poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) aqueous solution (PEDOT / PSS, 2.8wt% aqueous solution) and 2g of no Mix water and ethanol, add 0.2 g of dimethyl sulfoxide, stir magnetically at room temperature for 5 hours to make the solution evenly mixed, and then let stand for 90 minutes to obtain a uniform electrospinning precursor; use air-guided directional in-situ electrostatic The spraying device sprays a layer of conductive nanofiber film on the lower elastic protective film 1 prepared in step 1) to obtain the bottom electrospun n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com