System for treating waste incineration waste gas

A waste incineration and exhaust gas technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of high reaction temperature, large heat loss, and high energy consumption, so as to reduce the reaction temperature, save energy consumption, and meet the treatment requirements. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

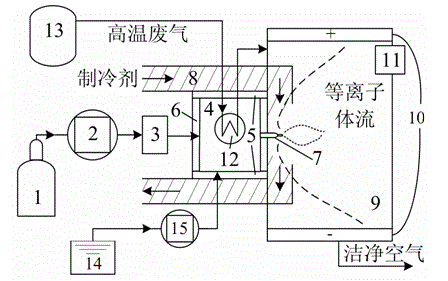

[0016] Such as figure 1 A system for treating waste incineration waste gas by plasma method as shown, including an inert gas storage tank 1, a pressurized pump 2, a flame retardant 3, a thermal ionization chamber 4 with a wall made of heat insulating material, 1# electrode 5, and Moving wall plate 6, nozzle 7, cooling system 8, plasma reaction chamber 9, 2# electrode 10, vacuum device 11, heat exchanger 12, garbage incinerator 13, pure water tank 14, water pump 15; inert gas storage tank The outlet of 1 is connected to the inlet of booster pump 2 through a pipeline, the outlet of booster pump 2 is connected to the inlet of flame retardant 3 through a pipeline, and the outlet of flame retardant 3 is connected to the thermal ionization of the wall plate as heat insulating material through a pipeline. The entrance of the chamber 4, the water outlet of the pure water tank 14 is connected to the water inlet of the water pump 15 through the pipeline, and the water outlet of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com