Efficient automobile exhaust thermoelectricity recovery device

A technology for automobile exhaust and recovery devices, which is applied in exhaust devices, mufflers, internal combustion piston engines, etc., can solve the problems of characteristics and stability without thorough consideration of heat transfer, long-term life cannot be guaranteed, and cannot be used in actual production and practical use. stage and other problems, to achieve the effect of improving reliability and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

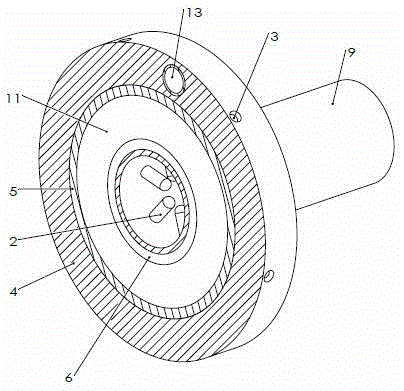

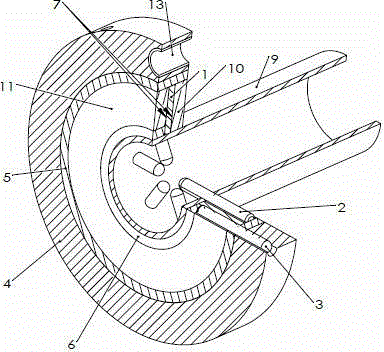

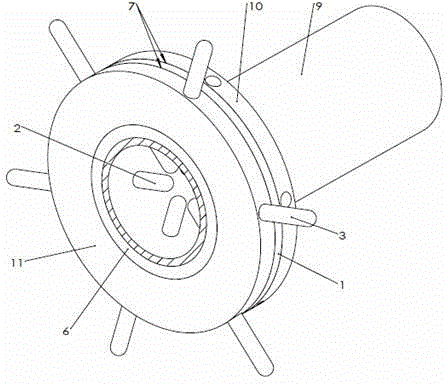

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as Figures 1 to 4As shown, a high-efficiency automobile exhaust thermoelectric recovery device consists of an annular thermoelectric chip 1, a high-temperature heat pipe 2, a medium-low temperature heat pipe 3, a metal foam 4, a polyamide gasket 5, a polytetrafluoroethylene insulation ring 6, and an ultra-thin high-temperature graphite pad Chip 7, intelligent circuit acquisition and MPPT module, stainless steel exhaust pipe 9, hot end circular aluminum alloy hot plate 10, cold end circular aluminum alloy hot plate 11 and shell 8; it is characterized in that: stainless steel exhaust pipe 9 Installed between the catalytic cracker and the muffler of the exhaust pipe system, a thermoelectric recovery device is added on it, and the waste heat of the exhaust gas in the exhaust pipe is conducted to the hot-end circular aluminum alloy hot plate 10 through the high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com