The preparation method of collagen fiber and genuine leather fiber leather which can be directly spun

A collagen fiber, direct technology, applied in the direction of fiber treatment, decomposition of fibrous substances, decomposition and restoration of textiles, etc., can solve problems such as insufficient binding force, damage to fibrils, waste of resources, etc., to increase surface roughness, improve Abrasion resistance and effect of shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

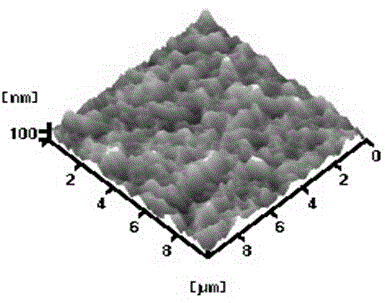

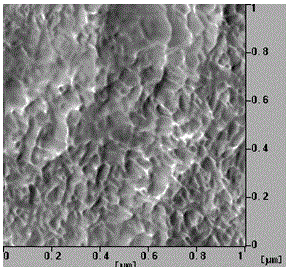

Image

Examples

Embodiment 1

[0041] Embodiment 1 adopts the following steps to prepare a kind of collagen fiber that can be directly used for spinning:

[0042] (1) Cutting: use wet blue leather as raw material, and cut it into the size required by production or equipment with a leather shearing machine;

[0043] (2) Ultrasonic pretreatment: Prepare the pretreatment solution, adjust the pH to 7~7.5, raise the temperature to 40~50°C, completely immerse the cut wet blue leather in the pretreatment solution for 12-24 hours, and then raise the temperature of the pretreatment solution to 50-60°C, adjust the pH to 7.5 to 8, then soak for 1-2 hours, and perform ultrasonic low-frequency short-term oscillation at the current temperature. The ultrasonic conditions used are: frequency 20-50kHz, power 200~600W, ultrasonic time 10-20 minutes; the pretreatment solution is prepared by mixing a sodium hydroxide solution with a mass concentration of 2-10% and a n-butanol solution with a mass concentration of 45-75% accord...

Embodiment 2

[0048] Embodiment 2 adopts the following steps to prepare a kind of collagen fiber that can be directly used for spinning:

[0049] (1) Cutting: use wet blue leather as raw material, and cut it into the size required by production or equipment with a leather shearing machine;

[0050] (2) Ultrasonic pretreatment: Prepare a polar solvent pretreatment solution rich in hydroxyl groups, adjust the pH to 7, raise the temperature to 45°C, completely immerse the cut wet blue leather in the pretreatment solution for 24 hours, and then pretreat The temperature of the solution is raised to 50°C, the pH is adjusted to 7.5 to 8, and then soaked for 2 hours, and ultrasonic low-frequency short-term oscillation is performed at the current temperature. The ultrasonic conditions used are: frequency 20kHz, power 200W, ultrasonic time 20 minutes; pretreatment solution It is prepared by mixing sodium hydroxide solution with a mass concentration of 2% and a polyethylene glycol solution with a mass...

Embodiment 3

[0055] Embodiment 3 adopts the following steps to prepare a kind of collagen fiber that can be directly used for spinning:

[0056] (1) Cutting: use wet blue leather as raw material, cut it into the size required by production or equipment with a leather shearing machine, immerse the wet blue leather raw material in a water pool for 2 to 5 minutes, and dry until the moisture content is 60 to 80%;

[0057] (2) Ultrasonic pretreatment: Prepare the pretreatment solution, adjust the pH to 7, raise the temperature to 50°C, completely immerse the wet blue leather in the pretreatment solution for 12 hours, then raise the temperature of the pretreatment solution to 55°C, and adjust the pH to 7.5 , then soak for 1.5 hours, and carry out ultrasonic low-frequency short-term oscillation at the current temperature. The ultrasonic conditions adopted are: frequency 40kHz, power 600W, ultrasonic time 10 minutes; the pretreatment solution is composed of 10% sodium hydroxide solution and A mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com