Method for producing acetone, butanol and ethyl alcohol through mixed-bacterial fermented cassava

A technology of mixed bacterial fermentation and Clostridium acetobutylicum, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of high energy consumption, high amylase and saccharification enzymes, and low total solvent yield. and other problems, to achieve the effect of high ethanol yield, avoid high cost and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

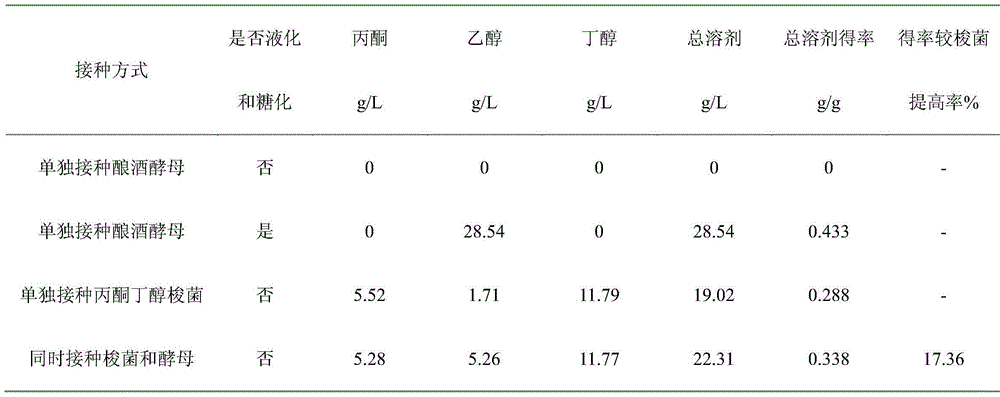

Examples

Embodiment 1

[0029] 1. Preparation of seed medium:

[0030] Preparation of Clostridium acetobutylicum seed culture medium: crush corn, pass through a 40-mesh sieve, add water to adjust the slurry to 5% (m / V), cook at 100°C for 20 minutes, and divide the corn mash into 20mL test tubes, 10mL test tubes, 121 Sterilize at ℃ for 120 min to obtain the seed culture medium of Clostridium acetobutylicum.

[0031] Saccharomyces cerevisiae seed medium preparation: glucose 20g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 115°C for 30min to obtain Saccharomyces cerevisiae seed medium.

[0032] 2. Preparation of cassava fermentation medium: crush cassava dry, pass through a 40-mesh sieve, add water to adjust slurry to cassava content 75g / L, bran 5g / L, sterilize at 121°C for 120min to obtain cassava fermentation medium.

[0033] 3. Fermentation process

[0034] (1) Clostridium acetobutylicum seed culture: heat-shock the spore suspension of Clostridium acetobutylicum at 100°C for 90s, cool it dow...

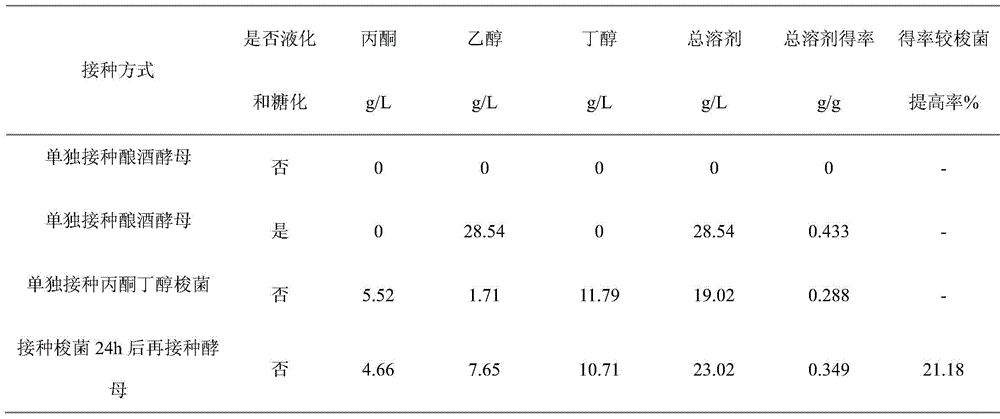

Embodiment 2

[0044] 1, preparation seed culture medium: with embodiment 1.

[0045] 2, preparation of cassava fermentation medium: with embodiment 1.

[0046] 3. Fermentation process:

[0047] (1) Clostridium acetobutylicum seed culture: with embodiment 1.

[0048] (2) Saccharomyces cerevisiae seed culture: with embodiment 1.

[0049] (3) Inoculate matured Clostridium acetobutylicum seed solution into 200 mL of cassava fermentation medium for anaerobic fermentation. The culture temperature is 37° C., the inoculum size is 5%, and the fermentation time is 24 hours. 24 hours after the inoculation of Clostridium acetobutylicum, inoculate the mature Saccharomyces cerevisiae seed liquid into the cassava fermentation medium of Clostridium acetobutylicum, mix evenly, and carry out mixed-bacteria fermentation, the inoculum size is 5%, and the fermentation temperature is 30°C. The fermentation time is 108h.

[0050] (4) Determination of acetone, butanol and ethanol content in the fermentation brot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com