Trichoderma atroviride strain capable of producing high-temperature-resistant feruloyl esterase and high-temperature-resistant cellulase and application thereof

A technology of ferulic acid esterase and cellulase, which is applied in the field of microorganisms, can solve the problems of insufficient tolerance, loss of ferulic acid esterase enzyme activity, and restrictions on the application of ferulic acid esterase, so as to achieve short fermentation period, The effect of low nutritional requirements and easy extraction and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

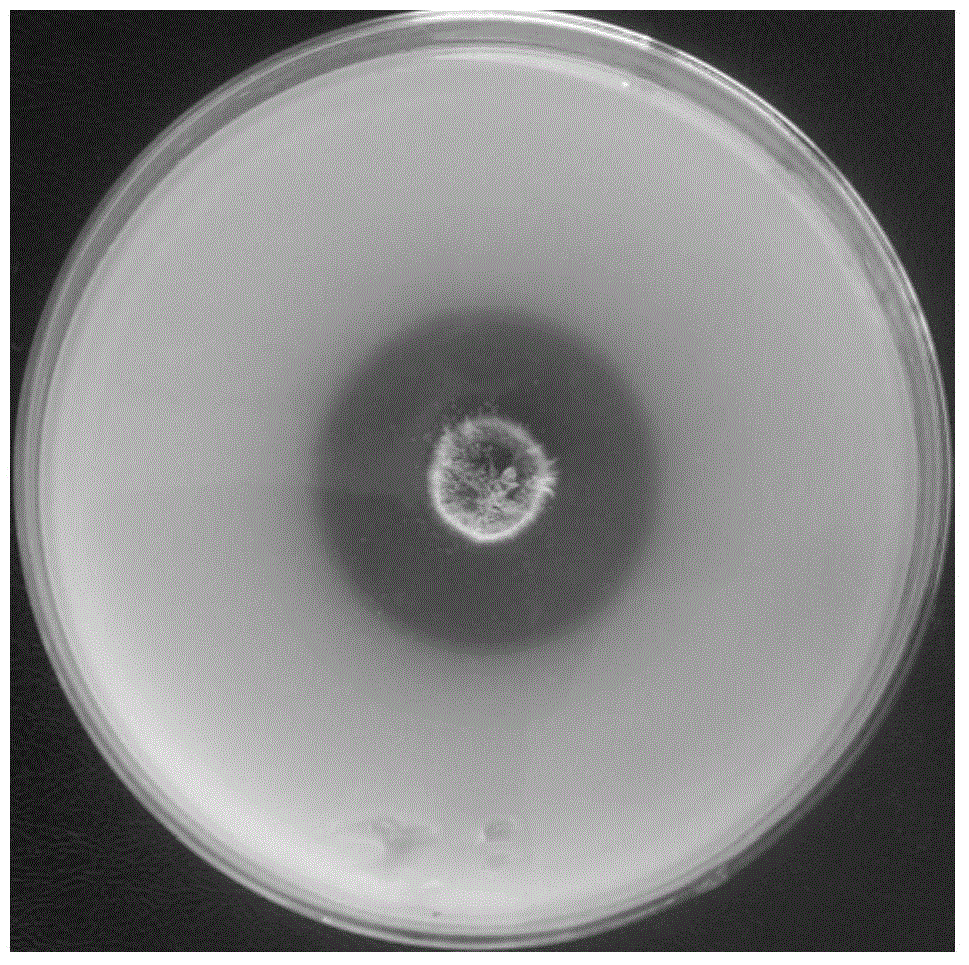

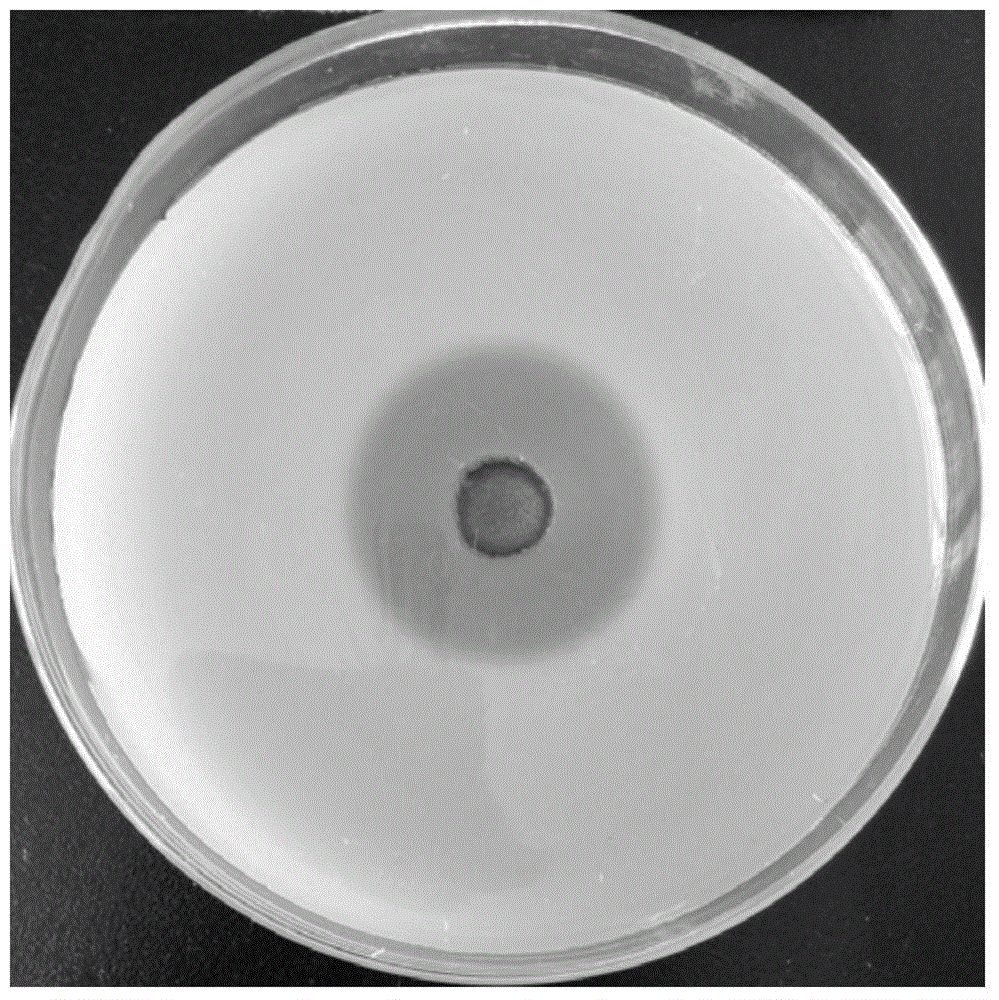

[0045] The present embodiment illustrates the screening method of Trichoderma dark green AWS26, and concrete steps are as follows:

[0046] Step 1, sampling and sample processing:

[0047] 10 soil samples were taken from the high-temperature fermented compost in Dahan Village, Yunlong District, Xuzhou City, Jiangsu Province. Weigh 5g of solid soil sample, put it into a triangular flask filled with glass beads and 50mL of sterilized saline, vibrate at 160r / min for 30min to make a suspension, and then put the triangular flask into a constant temperature shaking water bath at 60-70°C In the pot, shake at 100r / min for 20-30min to obtain a soil-like turbid solution.

[0048] Step 2, enrichment culture:

[0049] Take 2-4mL of the soil sample turbid solution obtained in step 1, add it to a 250mL Erlenmeyer flask containing 30-60mL enrichment medium 1, and place it in a constant temperature shaker at 45-50°C and a speed of 160-200r / min After culturing for 5-7 days, an enriched cult...

Embodiment 2

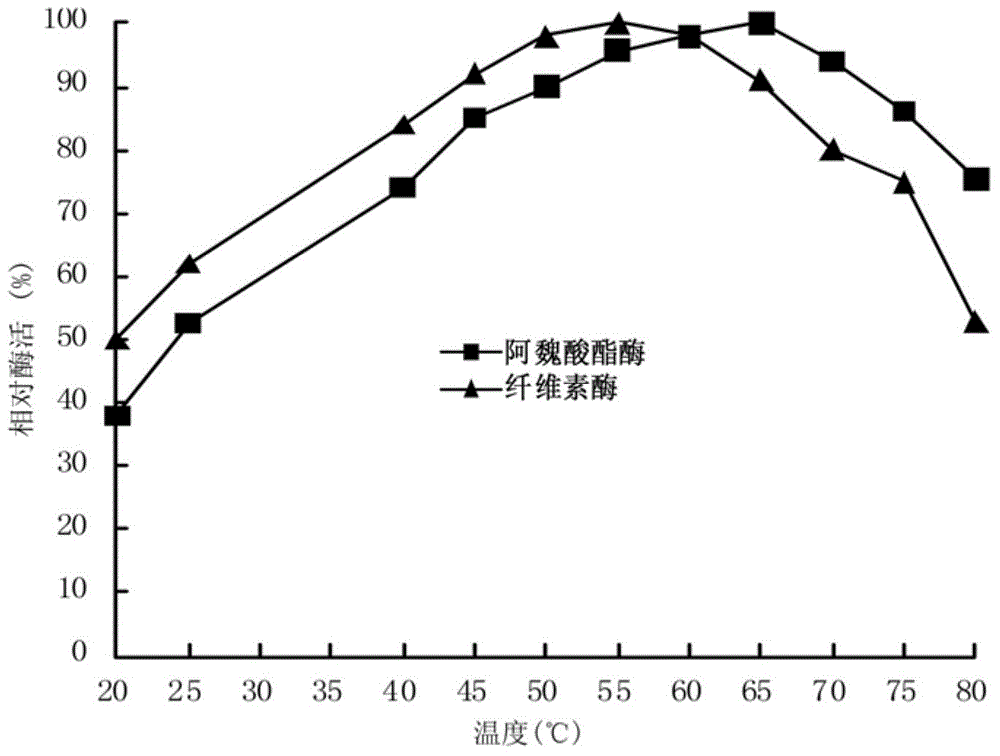

[0077] Example 2 Trichoderma dark viride producing high temperature resistant ferulic acid esterase and high temperature resistant cellulase is applied to feed raw material degradation

[0078] Dry corn straw powder 10g, bran 5g, ammonium sulfate 1g, soybean meal powder 1g, ammonium nitrate 0.4g, NaCl 0.5g, potassium dihydrogen phosphate 0.2g, MgSO4 0.05g, add according to the solid-liquid mass ratio 1:1.3 Ionized water, put the above feed into the Erlenmeyer flask, put it into the constant temperature and humidity incubator after sterilization and inoculation, adjust the temperature to 26-30°C, pH6.0. The inoculated strain is the activated strain AWS26 of the present invention. During the fermentation process, the Erlenmeyer flask was turned every day, and after 10 days of fermentation, the content changes of cellulose, hemicellulose and lignin were detected. The test results showed that among the fermentation raw materials, the degradation rate of lignin was 77.4%, the degr...

Embodiment 3

[0079] Example 3 Trichoderma dark viride producing high temperature resistant ferulic acid esterase and high temperature resistant cellulase is applied to ferment wheat bran to prepare ferulic acid

[0080] Add 50 g of bran, 1 g of ammonium sulfate, 2 g of peptone, 0.2 g of potassium dihydrogen phosphate, 0.05 g of magnesium sulfate, and 75 mL of water into a 500 mL Erlenmeyer flask, mix and sterilize. After PDA medium slant culture and inoculation of the Trichoderma dark green strain of the present invention, 30-35 ℃ culture 3-4d, then add sterile water 10ml in the slant and fully suspend spore, add 2ml spore suspension in the sterilized medium, After mixing well, culture at 30-35°C for 3-5 days, and turn over 2-3 times in the middle. Add deionized water to the fermented bran koji, stir well to disperse the bran koji, place it on a vibrating shaker at a speed of 100r / min, and extract at 50°C for 2h. Filter, centrifuge at 8000r / min for 20min, take the supernatant with a satur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com