Silica gel surface molecularly imprinted polymer with specific adsorption of DEHP and preparation method and application thereof

A surface molecular imprinting and species-specific technology, applied in selective adsorption, chemical instruments and methods, ion exchange, etc., can solve problems such as lack of coverage, instability, and chemical stability effects, and achieve high specificity recognition and selective adsorption , enhanced binding force, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

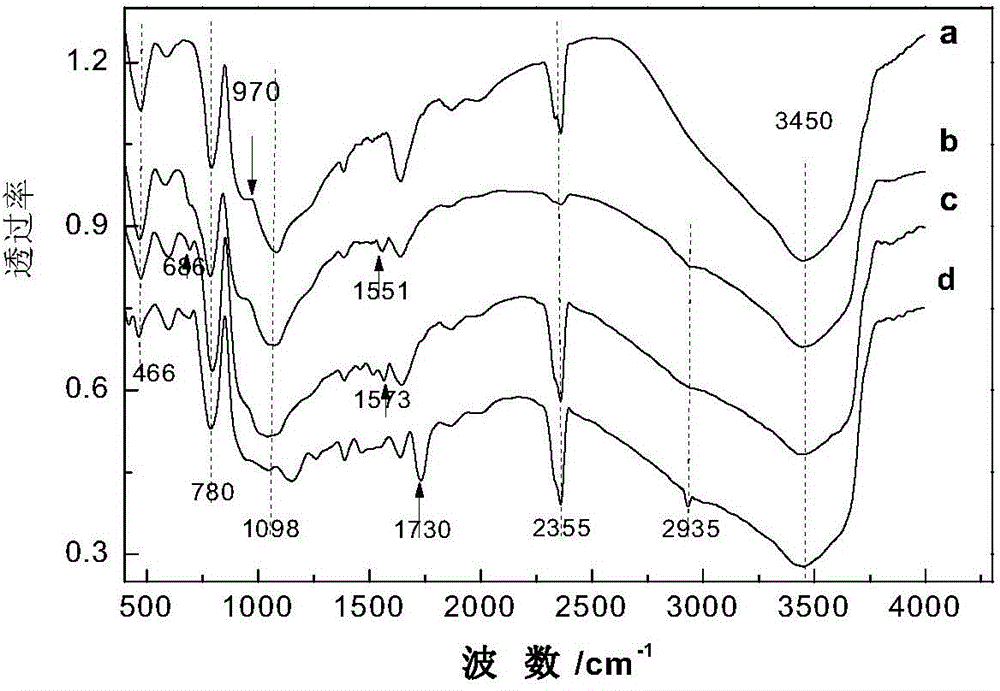

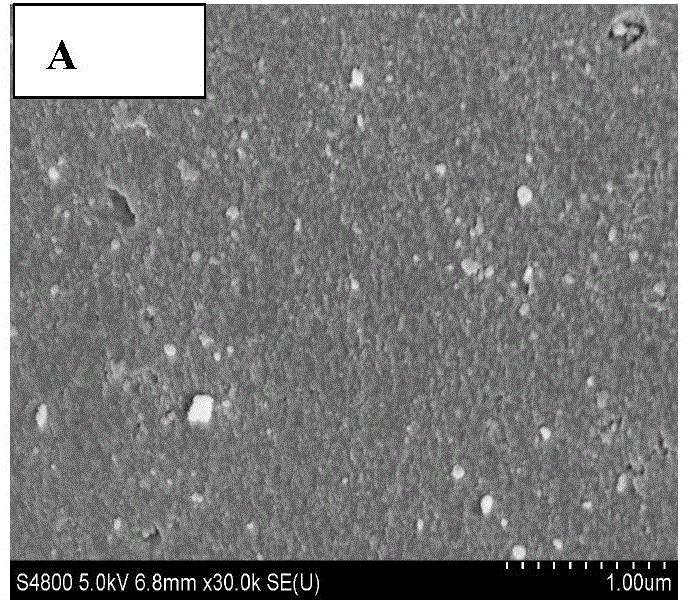

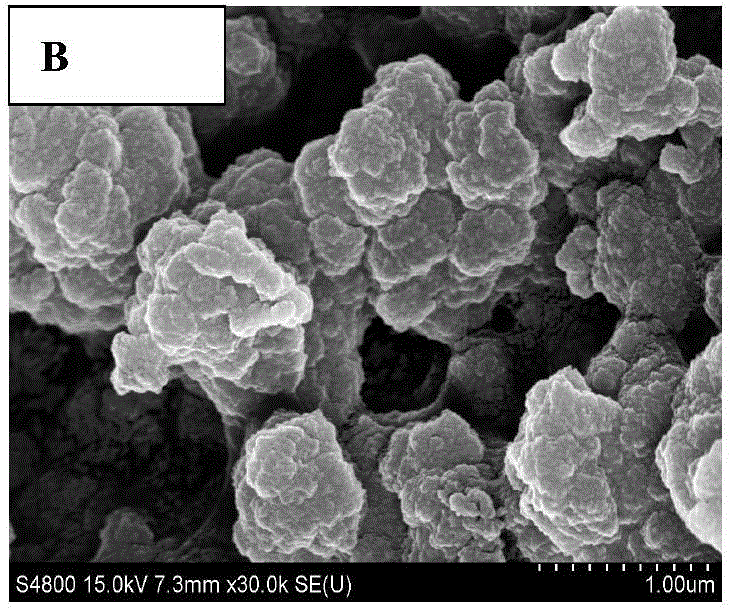

Embodiment 1

[0040] Take 15g of silica gel and add 200mL of hydrochloric acid solution with a mass fraction of 10%, heat and reflux in an oil bath at 120°C for 24h, wash with acetone and absolute ethanol respectively, then wash with distilled water until neutral, and vacuum dry at 150°C for 12h to obtain the activated Silica gel. Add 5g of activated silica gel into 50mL of toluene solution, ultrasonically disperse and degas for 30min, N 2 Add 15mL KH-550 dropwise under protection, then add 5mL triethylamine, heat and reflux at 90°C for 12h, alternately wash with toluene, acetone, methanol and then wash with distilled water, and vacuum dry at 60°C for 12h to obtain aminated silica gel. Take 4g of aminated silica gel and 80mL of toluene in a three-necked flask, N 2 Add 5 mL of acryloyl chloride dropwise under protection, stir for 10 min, then add 12 mL of triethylamine, stir and react at room temperature for 24 hours, wash the product with toluene, methanol, and deionized water several time...

Embodiment 2

[0047] Take 10g of silica gel and add it to 100mL of hydrochloric acid solution with a mass fraction of 5%, heat and reflux in an oil bath at 110°C for 15h, wash with acetone and absolute ethanol respectively, then wash with distilled water until neutral, and dry in vacuum at 130°C for 12h to obtain activation Silica gel. Add 3g of activated silica gel into 30mL of toluene solution, ultrasonically disperse and degas for 20min, N 2 Add 10mL KH-550 dropwise under protection, then add 5mL triethylamine, heat and reflux at 90°C for 10h, alternately wash with toluene, acetone, methanol, then wash with distilled water, and vacuum dry at 60°C for 12h to obtain aminated silica gel. Take 2g of aminated silica gel and 50mL of toluene in a three-necked flask, N 2 Add 4 mL of acryloyl chloride dropwise under protection, stir for 10 minutes, then add 10 mL of triethylamine, stir and react at room temperature for 20 hours, wash the product with toluene, methanol and deionized water several...

Embodiment 3

[0049]Take 20g of silica gel and add 200mL of hydrochloric acid solution with a mass fraction of 20%, heat and reflux in an oil bath at 130°C for 30h, wash with acetone and absolute ethanol respectively, then wash with distilled water until neutral, and vacuum dry at 160°C for 15h to obtain activated Silica gel. Take 10g of activated silica gel and add it to 80mL toluene solution, ultrasonically disperse and degas for 40min, N 2 Under protection, add 30mL KH-550 dropwise, then add 10mL triethylamine, heat and reflux at 120°C for 20h, alternately wash with toluene, acetone, methanol, then wash with distilled water, and vacuum dry at 80°C for 24h to obtain aminated silica gel. Take 6g of aminated silica gel and 120mL of toluene in a three-necked flask, N 2 Add 10 mL of acryloyl chloride dropwise under protection, stir for 10 min, then add 20 mL of triethylamine, stir and react at room temperature for 36 h, wash the product with toluene, methanol, and deionized water several tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com