Instant slow-release nitrogen fertilizer and preparation method thereof

A nitrogen fertilizer and slow-release technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of restricting the rapid popularization of water and fertilizer integration technology, high cost of irrigation and fertilization, lack of slow-release technology, etc. , reduce the number of irrigation, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

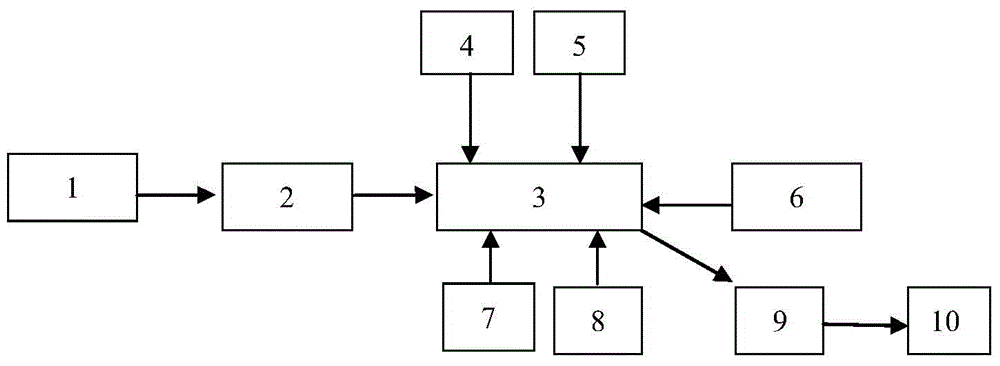

Image

Examples

Embodiment 1

[0023] Add 100kg of urea and 54.85kg of formaldehyde solution with a content of 36.5% (the molar ratio of urea to formaldehyde is 2.5:1) into the reaction kettle, and rapidly raise the temperature to 35-45°C under constant stirring, and use a concentration of 20% The sodium hydroxide solution is used to adjust the pH to 9.5-10, and the reaction is continued for about 1-2 hours to obtain a prepolymer of urea-formaldehyde. Then add organic acid (the weight ratio of oxalic acid, dodecylbenzenesulfonic acid and thioacetic acid is 1:2:0.8), until the pH of urea-formaldehyde prepolymer is 2-3, then add catalyzer 0.47kg (chlorine The weight ratio of ammonium chloride and ammonium persulfate is 1:0.25) and surfactant 0.16kg (the weight ratio of sodium dodecylbenzenesulfonate and alkyl alcohol ether carboxylate is 1:1.5), stir rapidly, about A solid low-molecular-weight slow-release nitrogen fertilizer can be produced within 5-10 minutes, and finally add 0.31 kg of modified synergist (...

Embodiment 2

[0025] Add 100kg of urea and 48.97kg of formaldehyde solution with a content of 36.5% (the molar ratio of urea to formaldehyde is 2.8:1) into the reaction kettle. The sodium hydroxide solution is used to adjust the pH to 9.5-10, and the reaction is continued for about 1-2 hours to obtain a prepolymer. Then add organic acid (the weight ratio of oxalic acid, dodecylbenzenesulfonic acid and thioacetic acid is 1:2:0.8), until the pH of the prepolymer is 2-3, then add catalyzer 0.45kg (ammonium chloride and the weight ratio of ammonium persulfate is 1:0.25) and surfactant 0.15kg (the weight ratio of sodium dodecylbenzenesulfonate and alkyl alcohol ether carboxylate is 1:1.5), stir rapidly, about 5- Solid low-molecular-weight slow-release nitrogen fertilizers can be generated within 10 minutes. Finally, 0.30 kg of modified synergist (the weight ratio of the mixture of polyaspartic acid and acetohydroxamic acid is 1:1.5) is added, and after being ground by a ball mill (95% of the pa...

Embodiment 3

[0027]Add 100kg of urea and 45.71kg of formaldehyde solution with a content of 36.5% (the molar ratio of urea to formaldehyde is 3:1) into the reaction kettle. The sodium solution is used to adjust the pH to 9.5-10, and the reaction is continued for about 1-2 hours to obtain a prepolymer. Then add organic acid (the weight ratio of oxalic acid, dodecylbenzenesulfonic acid and thioacetic acid is 1:2:0.8), until the pH of the prepolymer is 2-3, then add catalyzer 0.44kg (ammonium chloride and the weight ratio of ammonium persulfate is 1:0.25) and surfactant 0.146kg (the weight ratio of sodium dodecylbenzenesulfonate and alkyl alcohol ether carboxylate is 1:1.5), stir rapidly, about 5- Solid low-molecular-weight slow-release nitrogen fertilizers can be generated within 10 minutes. Finally, 0.29 kg of modified synergist (the weight ratio of the mixture of polyaspartic acid and acetohydroxamic acid is 1:1.5) is added and ground by a ball mill. (95% of the particles are less than 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com