Method for preparing foam glass by virtue of high-temperature liquid-state metallurgical clinker

A foam glass and slag technology, applied in the field of metal material processing, to achieve the effects of environmental friendliness, low energy consumption, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

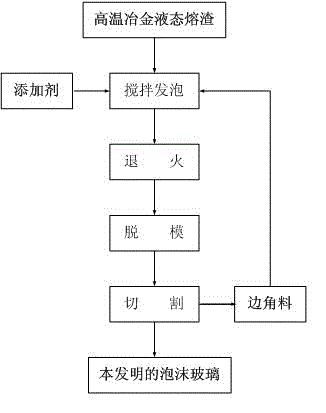

Image

Examples

Embodiment 1

[0024] (1) Put the blast furnace slag discharged from the metallurgical smelting furnace at a temperature of 1450°C directly into the homogeneous foaming furnace, add additives, and fully stir and foam under the waste heat of the slag at a stirring speed of 5 r / min , the stirring time is 0.4h, and the mixed foam of molten slag is obtained;

[0025] (2) Put the mixed foam of molten slag into the mold, use an annealing furnace with a cooling intensity of 20°C / min, lower the temperature to 600°C, and then anneal at a cooling rate of 1°C / min to obtain the slag Sintered body;

[0026] (3) Demould the sintered body of the molten slag, cut to obtain block material and leftover material, and the block material is foam glass.

[0027] The homogeneous foaming furnace is a pond kiln.

[0028] The additive is a cold auxiliary additive obtained by mixing the coolant, the conditioning agent, the cosolvent and the foaming agent evenly, wherein the coolant is a mixture of 10% scrap and 90% ...

Embodiment 2

[0032] (1) Put the silicon-manganese slag discharged from the metallurgical smelting furnace at a temperature of 1200°C directly into the homogeneous foaming furnace, add additives, and fully stir and foam under the waste heat of the slag at a stirring speed of 10 r / min, the stirring time is 0.2h, and the mixed foam of molten slag is obtained;

[0033] (2) Put the mixed foam of molten slag into the mold, use the annealing furnace, the cooling intensity is 30°C / min, reduce the temperature to 500°C, and then anneal at a cooling rate of 1.5°C / min to obtain the slag Sintered body;

[0034] (3) Demould the sintered body of the molten slag, cut to obtain block material and leftover material, and the block material is foam glass.

[0035] The homogeneous foaming furnace is an electric arc furnace.

[0036] The additive is a cold-state auxiliary additive obtained after uniformly mixing coolant, conditioner, cosolvent, and foaming agent, wherein the coolant is a mixture of 20% scrap...

Embodiment 3

[0040] (1) Put the high-temperature liquid nickel slag discharged from the metallurgical smelting furnace at a temperature of 1500°C directly into the homogeneous foaming furnace, add additives, and fully stir and foam under the residual heat of the slag at a stirring speed of 1 r / min, the stirring time is 0.8h, and the mixed foam of molten slag is obtained;

[0041] (2) Put the mixed foam of molten slag into the mold, use an annealing furnace with a cooling intensity of 40°C / min, lower the temperature to 700°C, and then anneal at a cooling rate of 2°C / min to obtain the slag Sintered body;

[0042] (3) Demould the sintered body of the molten slag, cut to obtain block material and leftover material, and the block material is foam glass.

[0043] The homogeneous foaming furnace is an induction furnace.

[0044] The additive is a cold-state auxiliary additive obtained after the coolant, the conditioning agent, the cosolvent, and the foaming agent are uniformly mixed, wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com