Synchronous nitrogen and carbon removal set and method for wastewater of aquatic product processing

A technology for processing wastewater and aquatic products, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of saving energy and materials, easy to popularize and apply, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

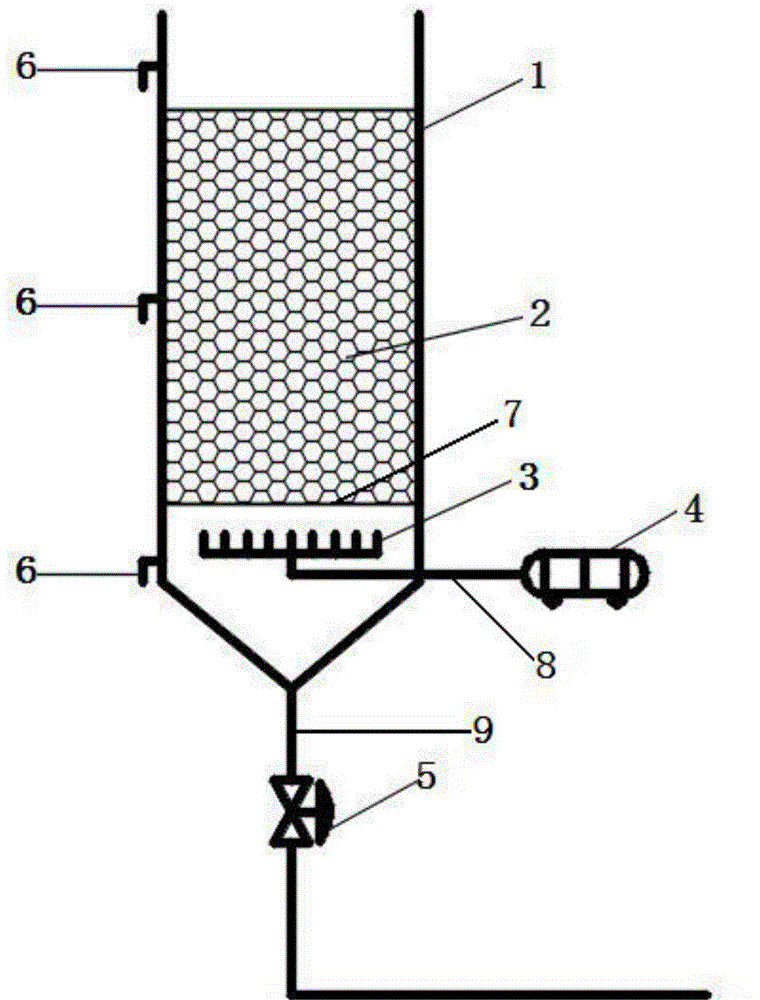

[0011] The main structure of the synchronous denitrification and carbon removal device for aquatic product processing wastewater described in this embodiment includes a reactor 1, a combined packing 2, an aerator 3, an air compressor 4, a sludge discharge valve 5, a valve 6, a fixed bracket 7, Intake pipe 8 and mud discharge pipe 9; reactor 1 is provided with a fixed bracket 7 for placing combined filler 2, and the combined filler 2 mainly composed of biofilm is installed on the fixed bracket 2 in a filling type, and the added combined filler The spun and twisted polypropylene fiber rope is used in series to press plastic discs with evenly distributed fiber filaments to form unit fiber bundles of the required length. The central rope is not knotted, and the tensile force is uniform. The film is agglomerated, the specific gravity of the combined filler is 1.02, the tensile strength is 6.8-7.1 g / single filament, the elongation is 4%, the pH tolerance range is 2-12, the combined f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com